Disperse dye and preparation process thereof

A disperse dye and preparation technology, applied in the field of dyes, can solve problems such as contamination, achieve the effects of improving surface roughness, bright color, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

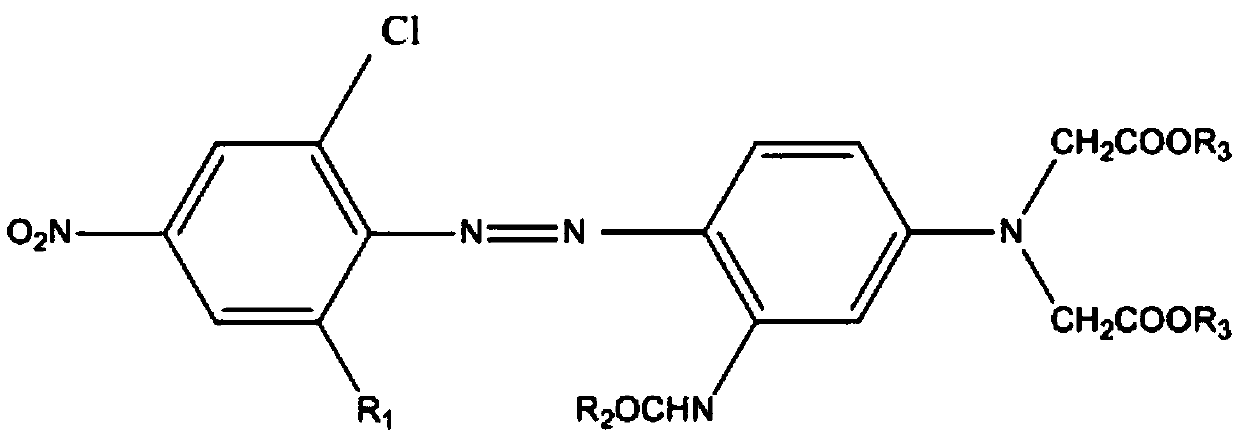

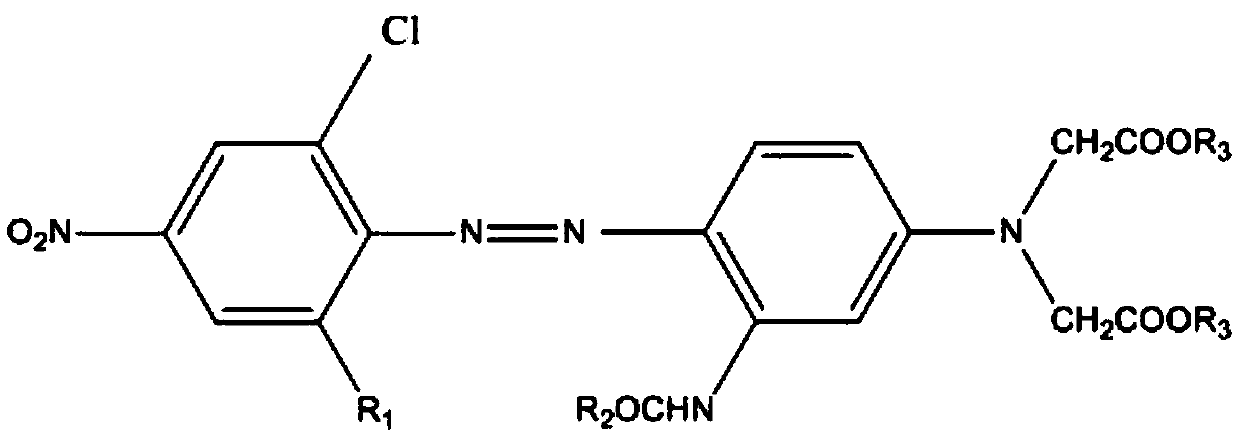

[0044] Preparation of dye monomer: the general formula is The compound diazotization, and the diazonium salt of this compound is coupled to obtained from above, where R 1 is chlorine or bromine, R 2 is methyl or ethyl, R 3 is methyl or ethyl.

Embodiment 1

[0047] The invention discloses a preparation process of disperse dyes, comprising the following steps:

[0048] S1, first mix the silica sol and distilled water, and adjust the pH value to 4;

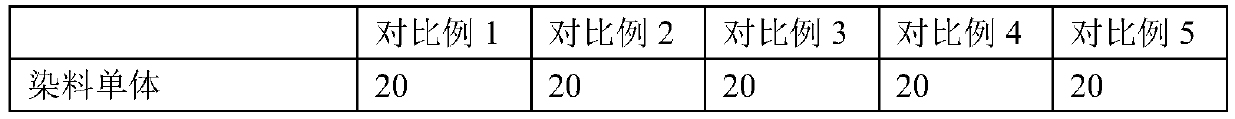

[0049] S2. Then add dye monomer, 6-bromo-2,4-dinitroaniline, dispersant and disperse blue 2BLN to obtain a preliminary mixture, stir and mix at 45°C, and then grind with a sand mill to obtain a dispersion dye. The content of each component is shown in Table 1 below.

Embodiment 2

[0051] The invention discloses a preparation process of disperse dyes, comprising the following steps:

[0052] S1, first mix the silica sol and distilled water, and adjust the pH value to 5;

[0053] S2. Then add dye monomer, 6-bromo-2,4-dinitroaniline, dispersant and disperse blue 2BLN to obtain a preliminary mixture, stir and mix at 50°C, and then grind with a sand mill to obtain a dispersion dye. The content of each component is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com