ITO rotating target binding method

A technology of rotating target and binding, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of ITO target scrap, uneven welding layer, back tube deformation, etc., to reduce labor Operation and human error, improve safety factor, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0038] A method for binding an ITO rotating target, comprising the steps of:

[0039] 1) Metallization pretreatment of the ITO target tube, sending a single segment of the ITO target tube to the automatic ultrasonic indium coating equipment, including the following sub-steps.

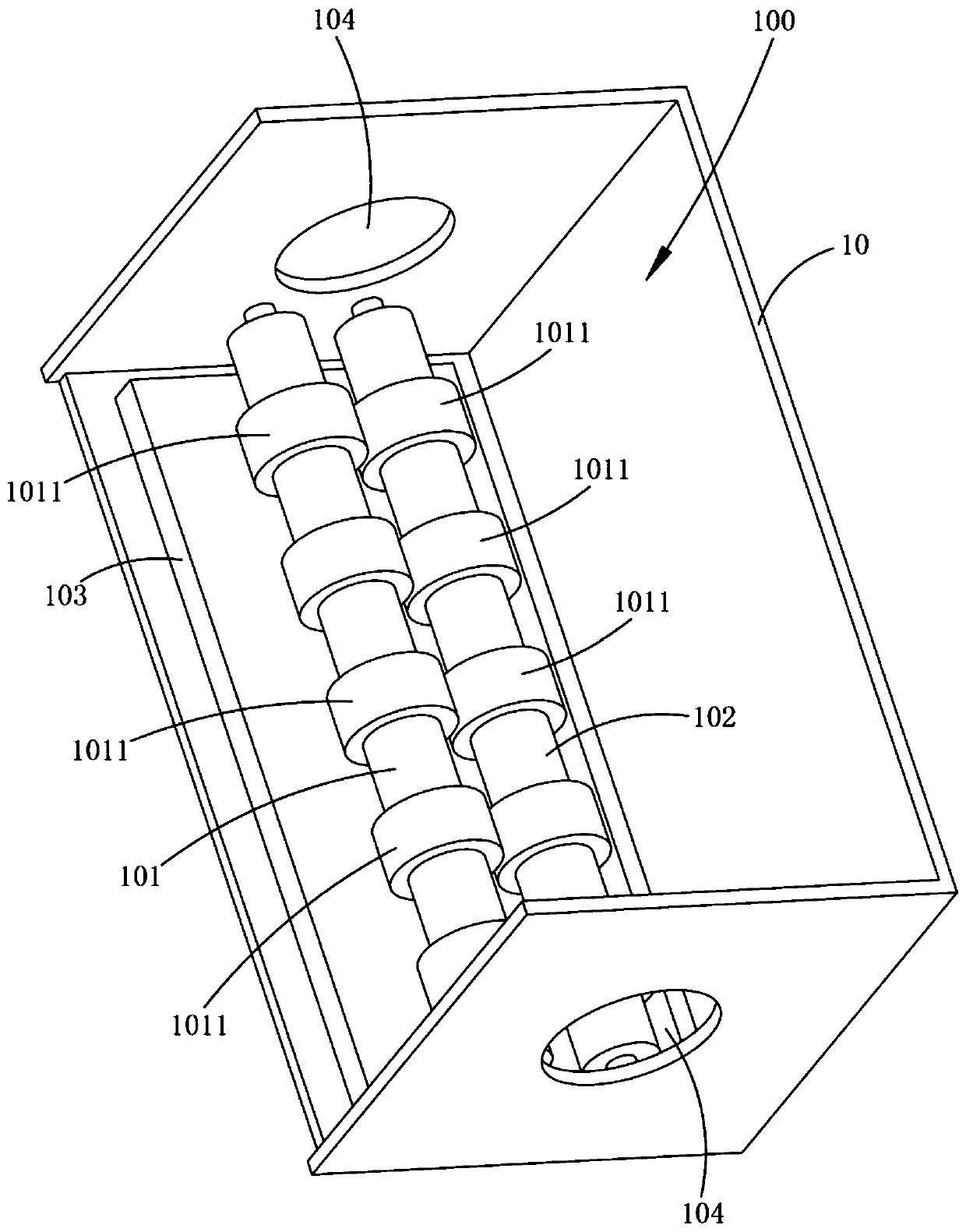

[0040] 1.1) The high temperature box 10 of the automatic ultrasonic indium coating equipment is used to heat up the temperature of the single-section ITO target tube, and the temperature of the ITO target tube is raised to 200 °C at a heating rate of 1.2-1.6 °C / min.

[0041] 1.2) Manually add molten indium to the inner tube wall of the ITO target tube through a spoon.

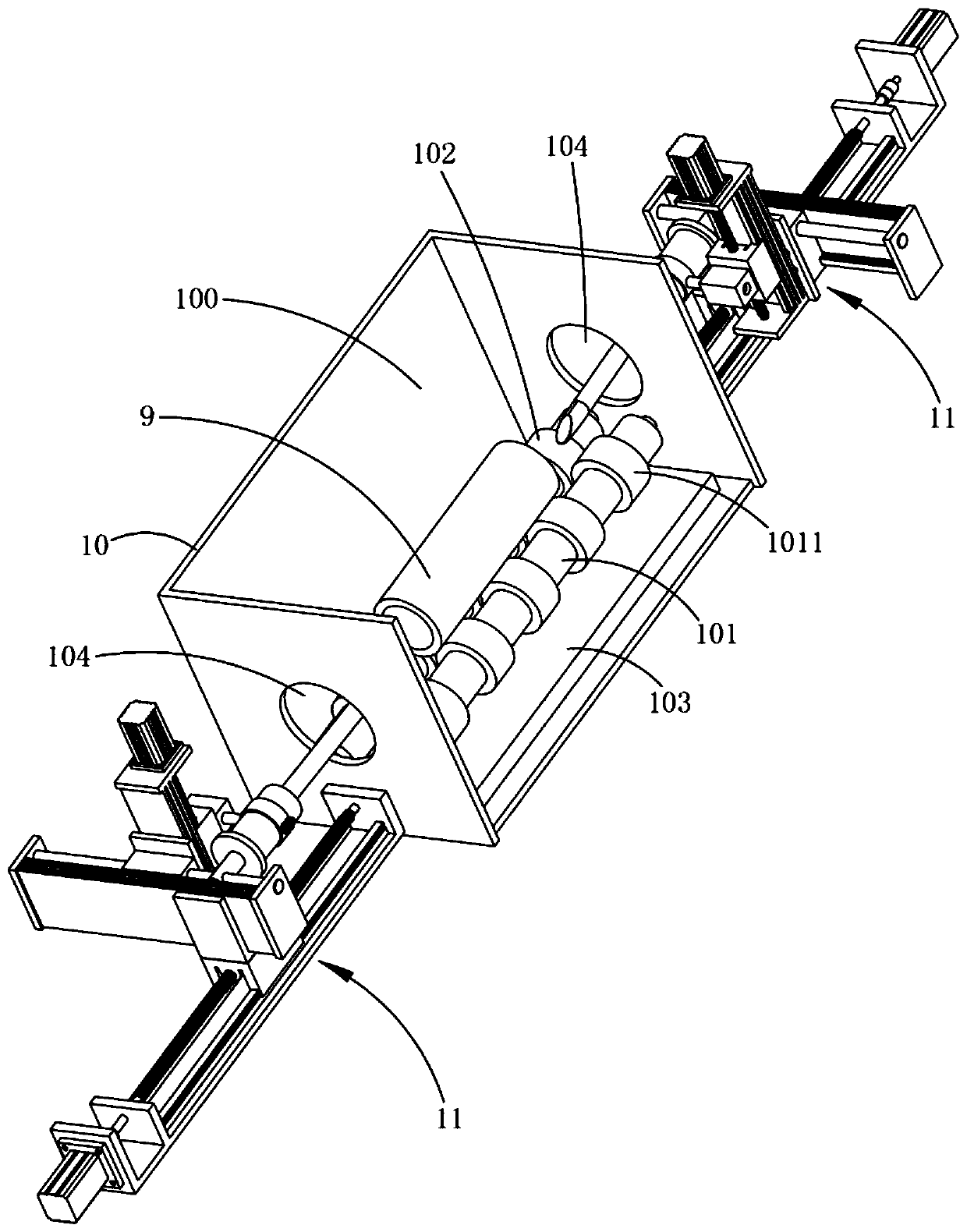

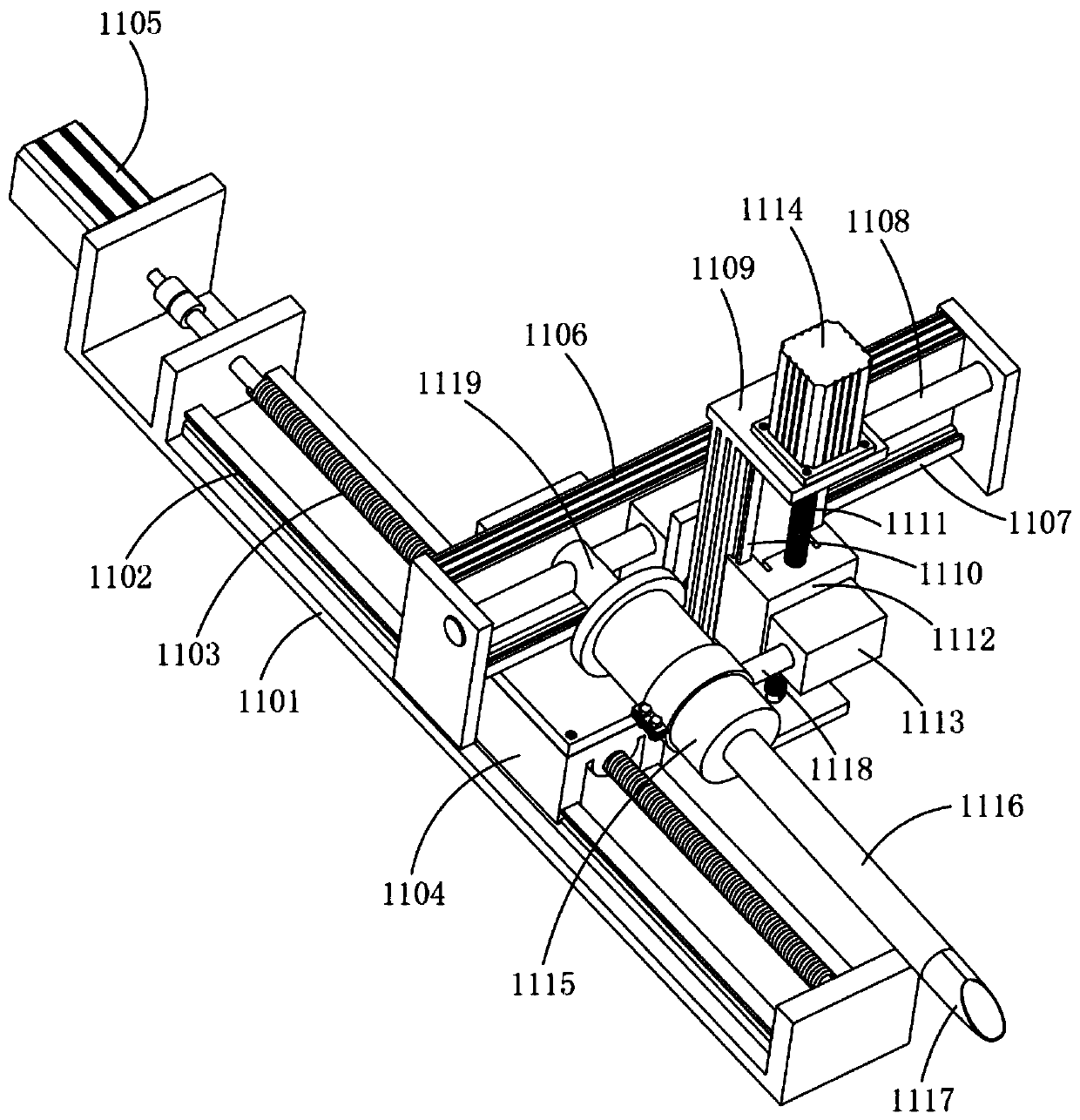

[0042] 1.3) The ITO target tube is driven to rotate on its axis by means of the back-up roller device arranged in the high temperature box 10, and at the same time, the ultrasonic coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com