Corrosion-resistant stainless steel concrete beam

A concrete beam, anti-corrosion technology, applied in the direction of joists, girders, trusses, etc., can solve problems such as structural durability decline, concrete cracking, corrosion, etc., and achieve the effect of improving service life, reducing maintenance costs, and solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

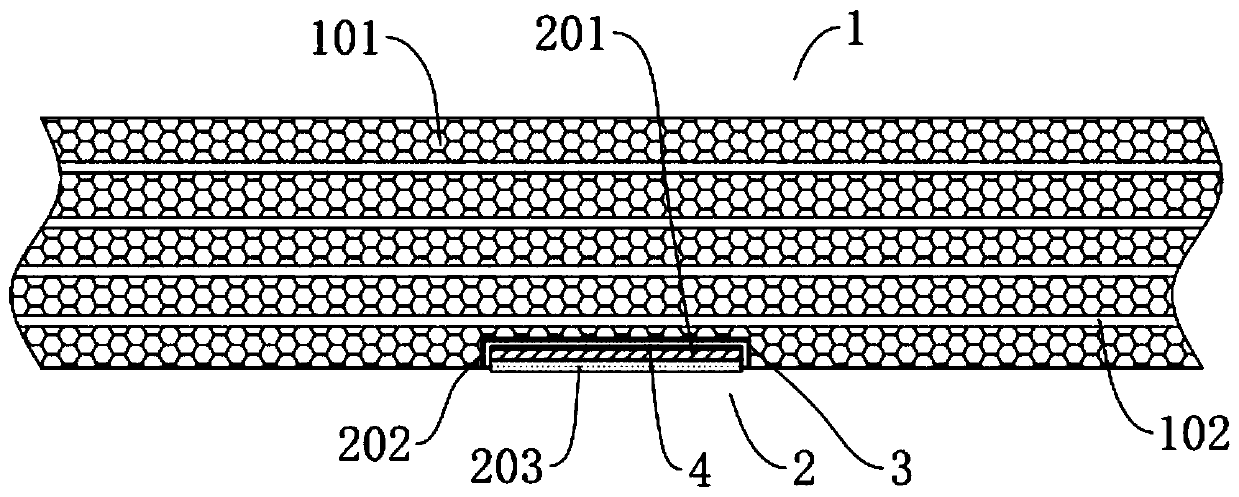

[0022] Please refer to the attached figure 1 , a corrosion-resistant stainless steel concrete beam, including a beam body 1, the beam body 1 includes a corrosion-resistant concrete structure 101 and a stainless steel bar structure 102, the stainless steel bar structure 102 is placed inside the corrosion-resistant concrete structure 101, the A support structure 2 is provided below the anti-corrosion concrete structure 101. The support structure 2 includes a support steel plate 201, a sealant 202, and a rubber pad 203. An embedded groove 3 is arranged under the anti-corrosion concrete structure 101. The embedded groove 3 is covered with a layer of stainless steel plate 4, the supporting steel plate 201 is embedded in the slot 3, a rubber pad 203 is placed under the supporting steel plate 201, and the rubber pad 203 and the supporting steel plate 201 are fixed by expansion screws .

[0023] Specifically, the joint between the caulking groove 3 and the stainless steel plate 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com