High-temperature lava, magma and molten liquid class waste heat recovery multi-stage rotating heat absorption head

A technology of waste heat recovery and lava, which is applied in the field of magma, molten liquid waste heat recovery multi-stage rotating heat absorption head, high temperature lava, can solve the problem of low utilization rate of heat exchange medium, and achieve the effect of improving the utilization rate of heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

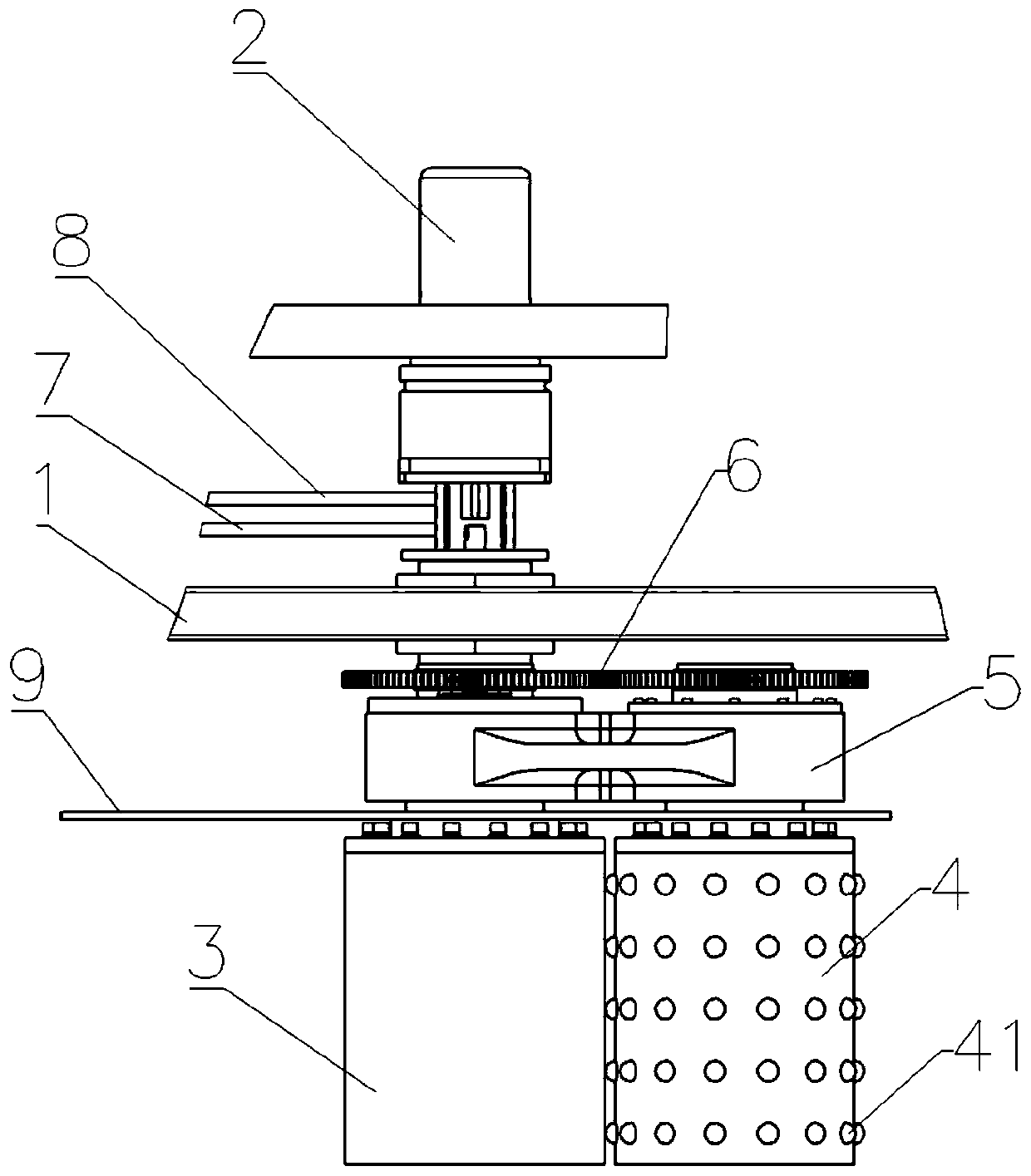

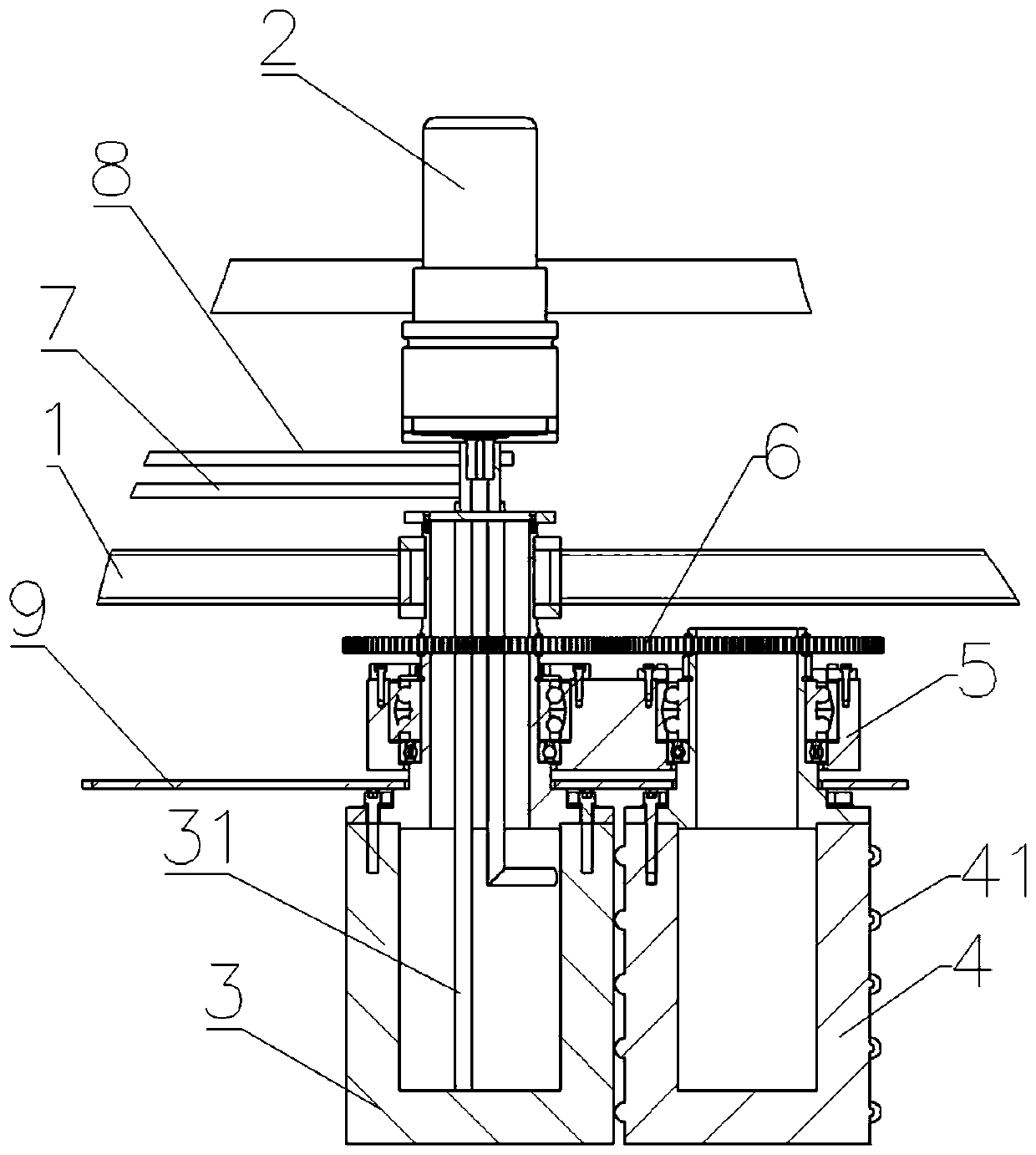

[0030] The multi-stage rotating heat-absorbing head for recovering waste heat from high-temperature lava, magma, and molten liquid includes a mounting frame 1, and a motor 2 is fixed on the left side of the top of the mounting frame 1. The bottom of the mounting frame 1 is provided with a heat absorption roller 3 and a granulation roller 4 positioned on the right side of the heat absorption roller 3, and the axes of the heat absorption roller 3 and the granulation roller 4 are all vertically arranged. A transmission structure is provided between the heat absorbing roller 3 and the granulating roller 4 .

[0031] The top of the heat absorbing roller 3 is coaxially fixed with a first rotating shaft, and the top of the granulation roller 4 is coaxially fixed with a second rotating shaft. The transmission structure includes a driving gear fixed coaxially with the first rotating shaft and a driven gear fixed coaxially with the second rotating shaft, and the first driving gear meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com