Grinding machine with fixing function

A fixed function, grinding machine technology, used in grinding machines, manufacturing tools, grinding workpiece supports, etc., can solve problems such as affecting grinding quality, inability to fix materials, grinding offset, etc., to improve grinding quality, increase clamping efficiency, increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

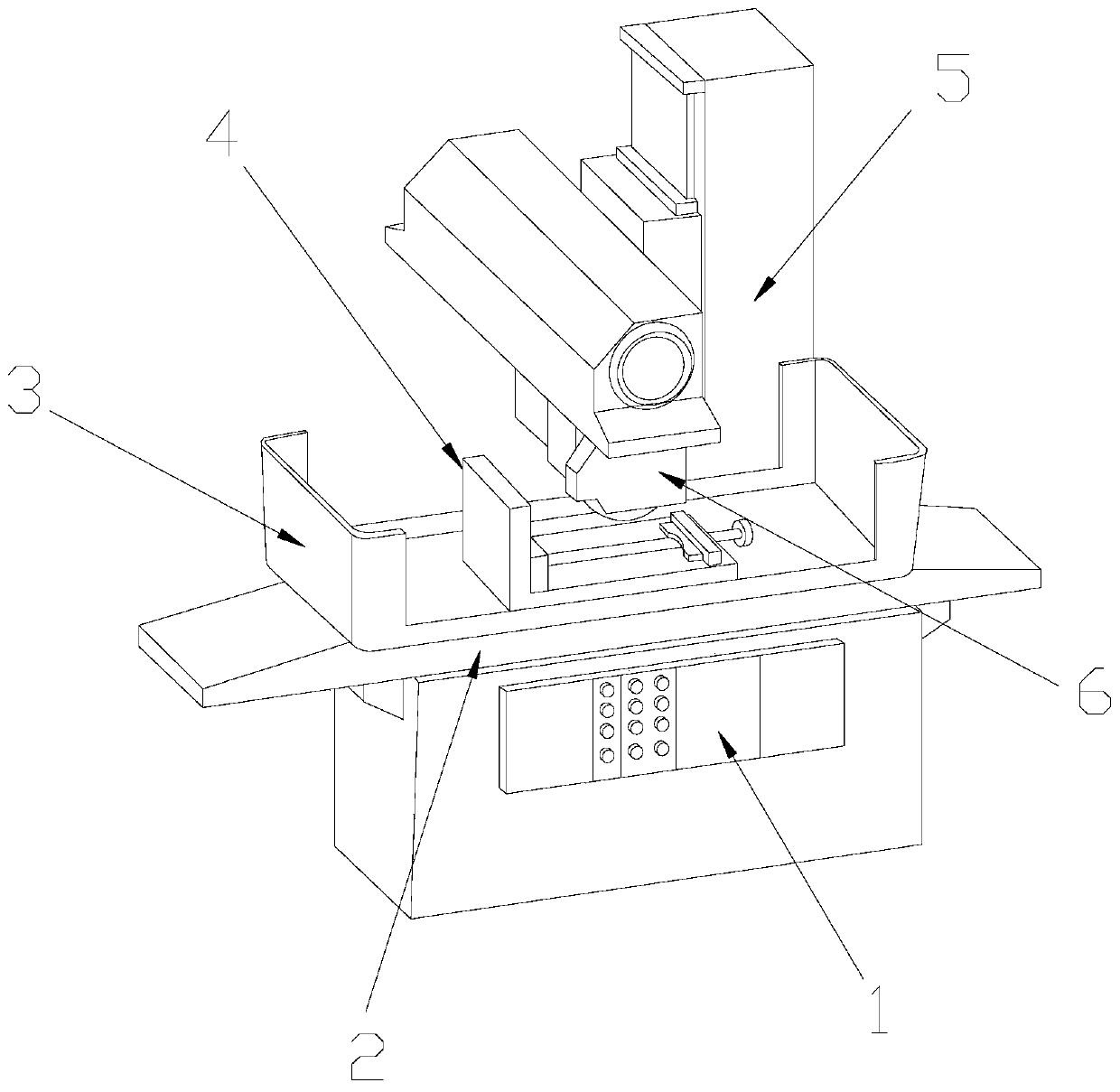

[0029] see Figure 1-Figure 3 , the present invention provides a kind of grinder with fixed function, and its structure comprises grinder 1, workbench 2, baffle plate 3, fixing mechanism 4, driving device 5, grinding mechanism 6, and described grinder 1 top is provided with workbench 2 , the grinder 1 is connected to the workbench 2, the surface of the workbench 2 is provided with a baffle 3, the workbench 2 and the baffle 3 are an integrated structure, and the middle of the top of the workbench 2 is The position is provided with a fixing mechanism 4, the workbench 2 is connected with the fixing mechanism 4, the driving device 5 is arranged on the rear end of the grinding machine 1, the grinding machine 1 and the driving device 5 are movably connected, and the A grinding mechanism 6 is installed under the front end of the driving device 5;

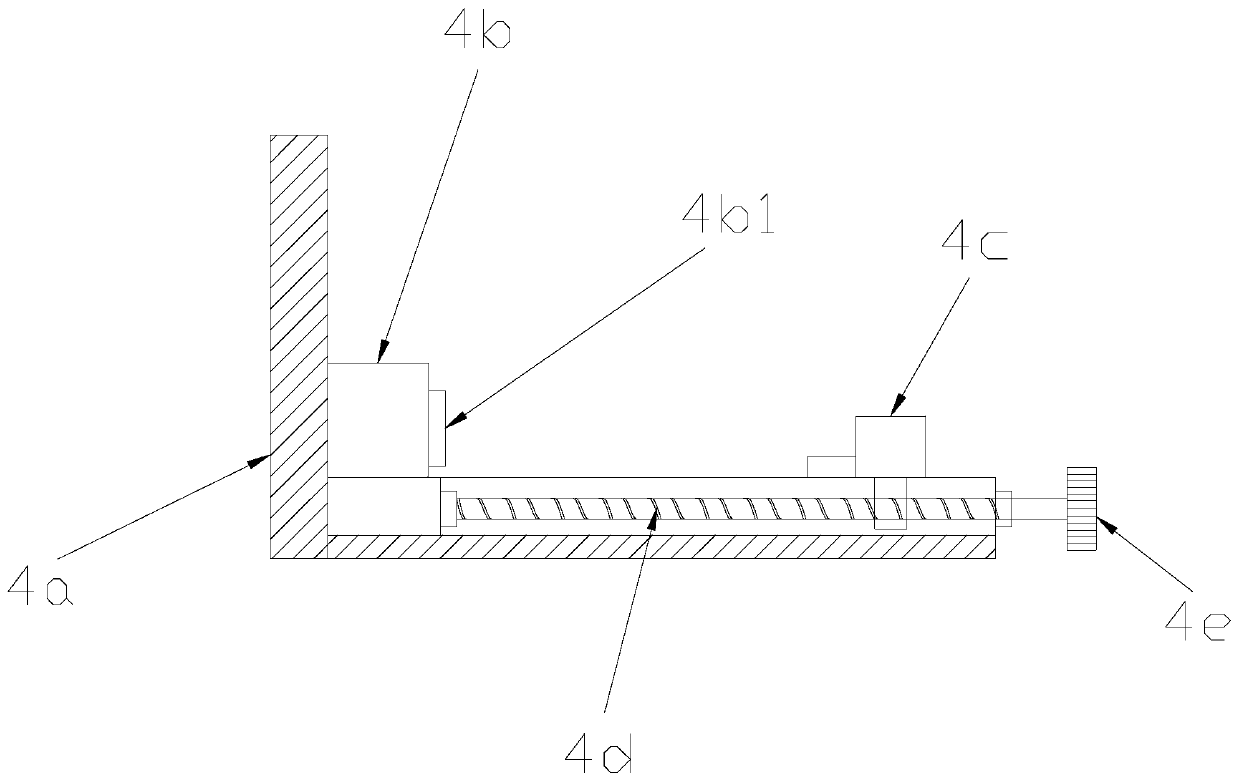

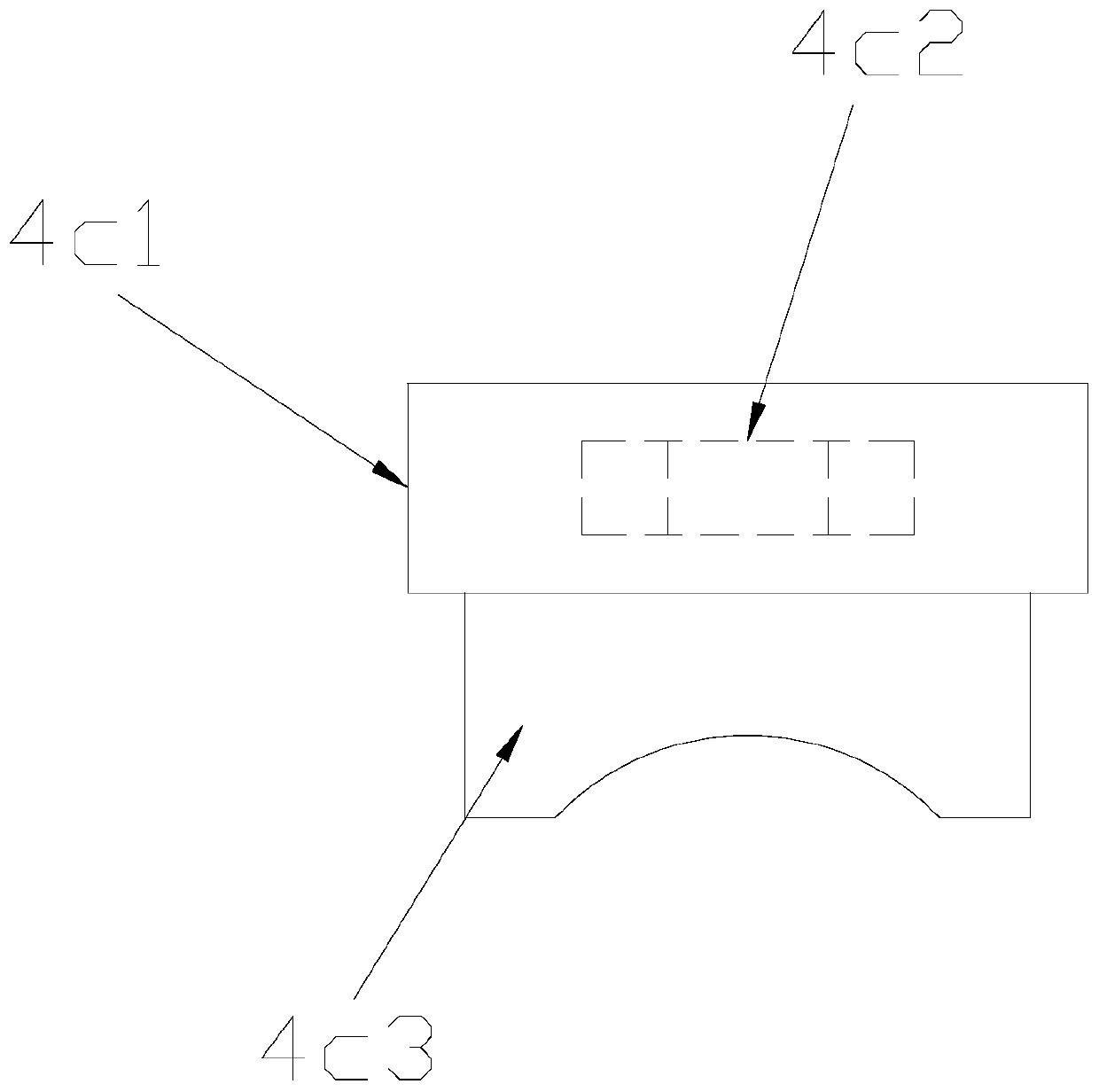

[0030] The fixing mechanism 4 is composed of an L-shaped support 4a, a fixed clip 4b, a clamping mechanism 4c, a screw mandrel 4d, and a...

Embodiment 2

[0036] see Figure 1-Figure 6 , the present invention provides a grinding machine with a fixed function, the grinding mechanism 6 is composed of a bracket 6a, a grinding wheel shaft 6b, an air induction mechanism 6c, a chip collecting box 6d, a pull ring 6e, a chip guide plate 6f, and a rejecting mechanism 6g, The inner side of the support 6a is provided with a grinding wheel shaft 6b, the support 6a is matched with the grinding wheel shaft 6b, and one end of the grinding wheel shaft 6b is provided with a draft mechanism 6c, and the described grinding wheel shaft 6b and the draft mechanism 6c tenon connection, the right side of the bracket 6a is provided with a dust collection box 6d, the bracket 6a is connected with the dust collection box 6d, the surface of the dust collection box 6d is provided with a pull ring 6e, and the The dust collection box 6d and the pull ring 6e are an integrated structure, the inside of the bracket 6a is provided with a chip guide plate 6f, the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com