Photo-curing 3D printing equipment and image exposure system thereof

A technology of 3D printing and exposure system, applied in the field of image exposure system, can solve problems such as limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

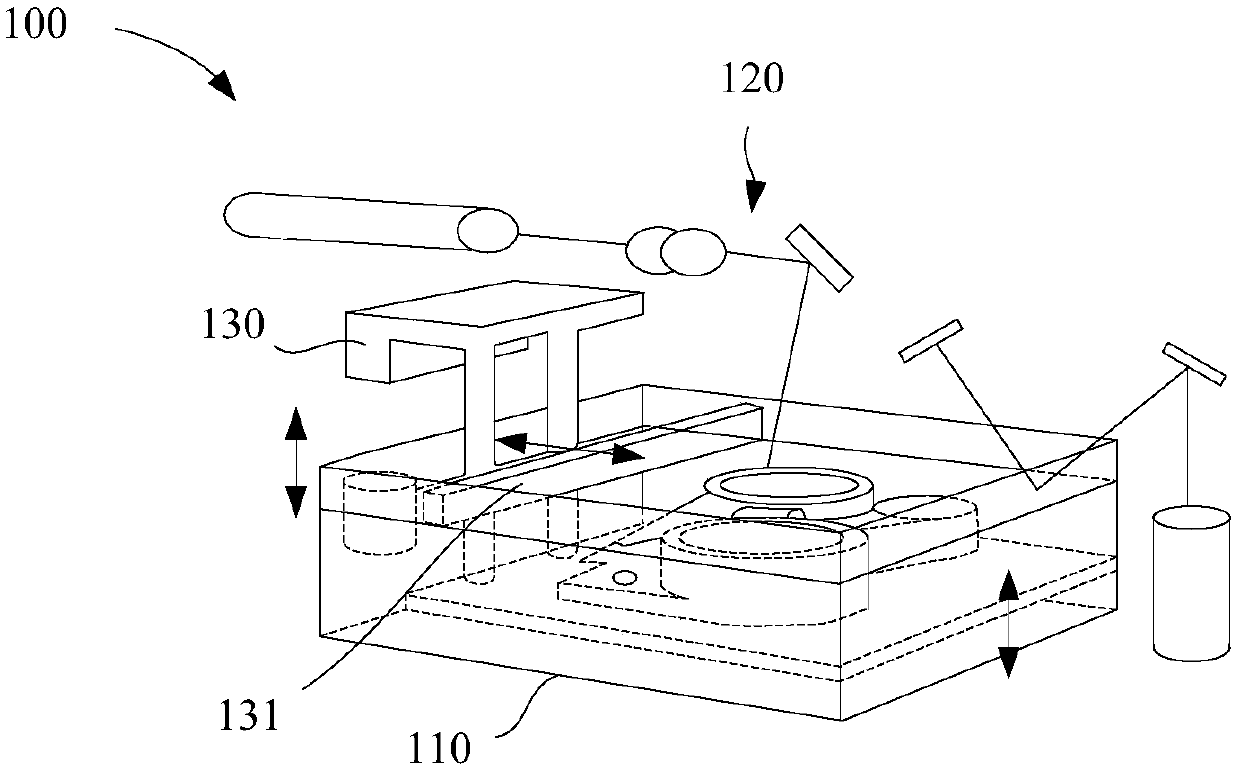

[0063] The embodiment of the present invention describes a 3D printing device and its image exposure system, and the image exposure system uses a silicon-based liquid crystal panel as an area array image source.

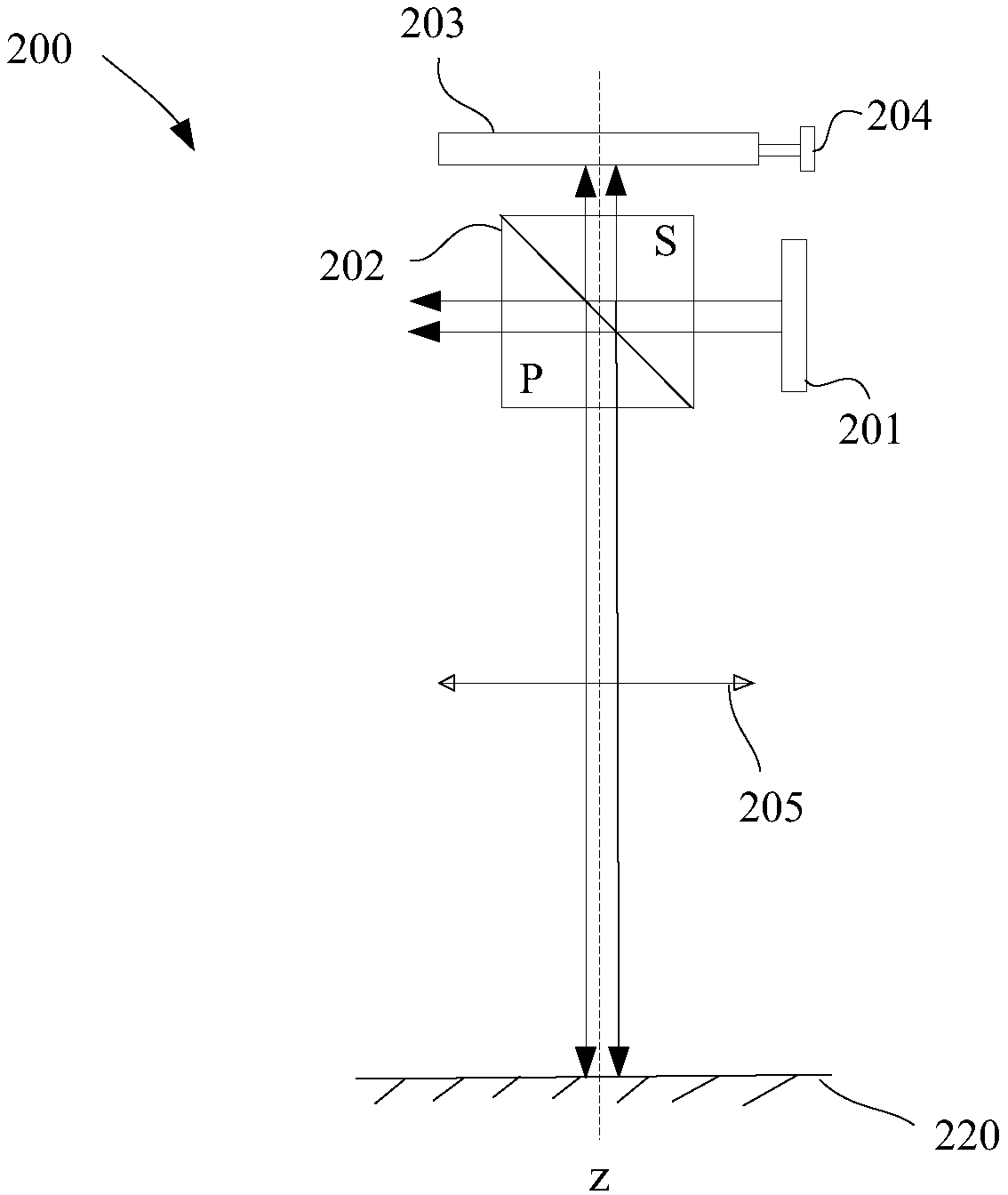

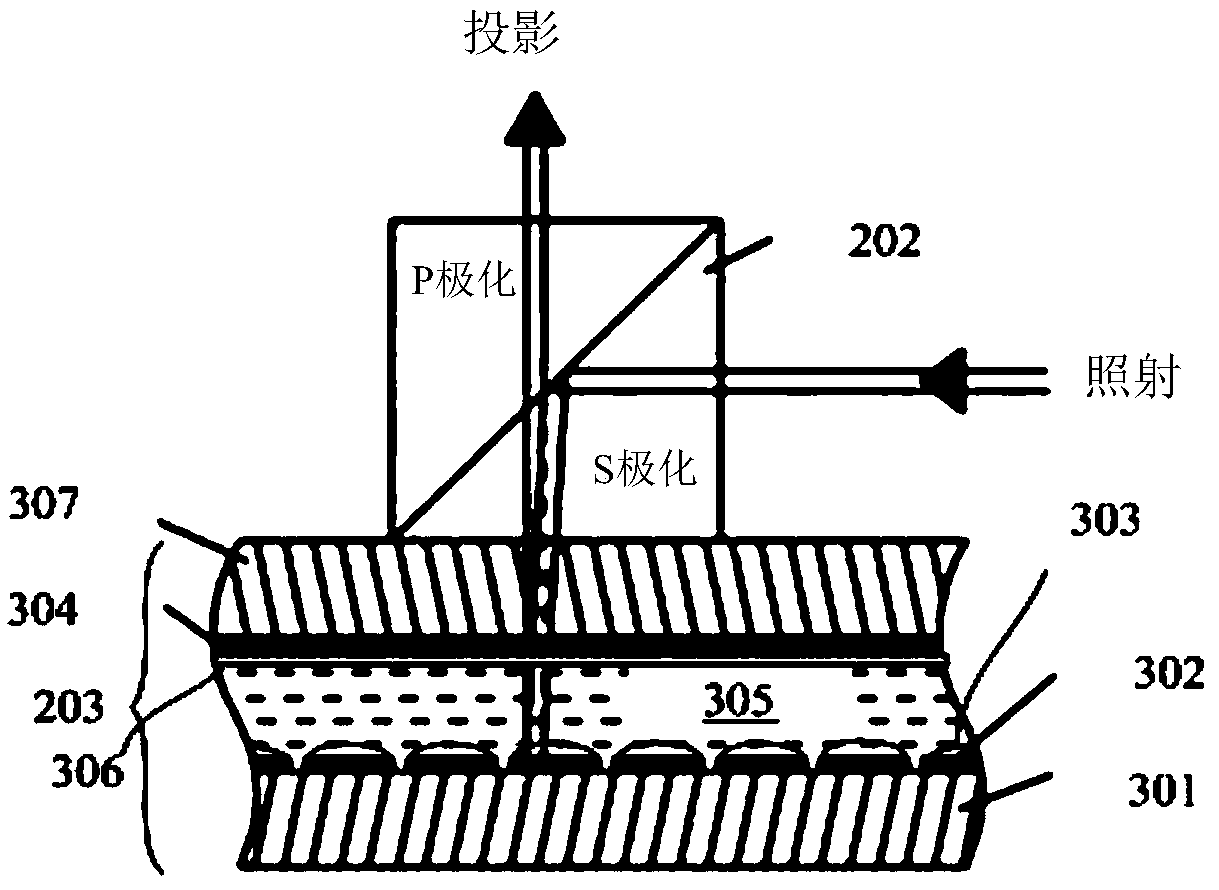

[0064] figure 2 An image exposure system of a 3D printing device according to an embodiment of the present invention is shown. refer to figure 2 As shown, the image exposure system 200 of this embodiment includes a light source 201, a polarizing beam splitter prism 202, a liquid crystal on silicon (LCOS) panel 203, a micro-displacement mechanism 204, a projection lens 205 and a controller (not shown). For the sake of clarity, components not relevant to the present invention are not shown.

[0065] The light source 201 is used to generate light beams to be irradiated onto the LCOS panel 203 . The wavelength of the light emitted by the light source 201 depends on the cured photosensitive material. For example, when UV resin is selected as the photosensitive mater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap