UV-LED cured inkjet ink and preparation method thereof

A UV-LED and inkjet ink technology, which can be used in ink, household utensils, applications, etc., can solve the problems of narrow wavelength range, low power and irradiation, and single wavelength peak, and achieve moderate hardness and broad development prospects. good fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] 1. Detection method:

[0079] (1) Particle size: Dilute the ink or color paste with a solvent 500-2000 times according to the pigment concentration, and use a laser particle size analyzer to measure the average particle size range D50.

[0080] (2) Viscosity: NDJ-5S rotational viscometer from Shanghai Nirun Intelligent Technology Co., Ltd. is used;

[0081] (3) Surface tension: BZY-1 surface tension meter produced by Shanghai Hengping Instrument Factory was used to test;

[0082] (4) Curing speed

[0083] Power of UV-LED lamp: electric power 610W; radiation 8W / cm 2 , the lamp distance is about 6mm, and the energy of one trip on the conveyor belt is: 300-600mj / cm 2 . Cured was judged to have been cured by rubbing a finger on the printing surface whereby it was observed that the ink was not smeared or smeared on the surface.

[0084] (5) Pencil hardness test reference standard: GB / T9286-1998

[0085] Using a glass substrate, scrape the ink layer into a thin layer wi...

Embodiment 9-12

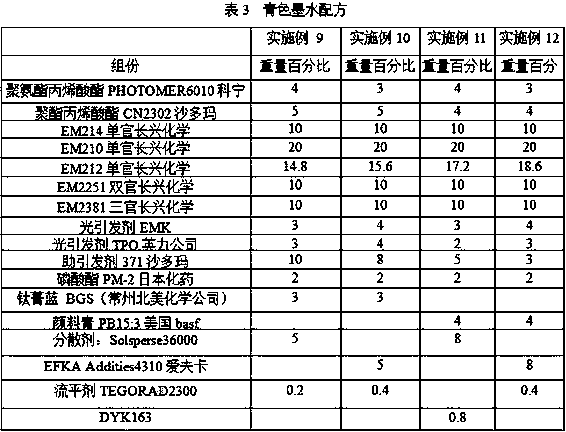

[0107] Embodiment 9-12 cyan ink formula table 3:

[0108]

[0109] Manufacture method: adopt the method identical with embodiment 1-4.

[0110] Embodiment 13-16 black ink formula sees table 4:

[0111]

[0112] Manufacture method: adopt the method identical with embodiment 1-4.

[0113] Example 17 and 21-22 spot color purple formula, embodiment 18-20 spot color green formula are shown in Table 5:

[0114]

[0115] Manufacture method: adopt the method identical with embodiment 1-4.

[0116] 3. The performance testing results are shown in Table 6.

[0117]

[0118] 4 Conclusion:

[0119] From the above data, it can be seen that the UV inkjet ink of the present invention does not contain organic solvents and has the characteristics of green environmental protection; the ink can be cured instantly under the irradiation of LED lamps, and the appearance is not sticky, which meets the requirements of fast printing; the ink fluency is good; Moderate hardness, scratch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com