A kind of laser additive manufacturing sinking roller composite shaft sleeve and its preparation method

A composite shaft sleeve, laser additive technology, applied in additive processing, metal material coating process, coating and other directions, to achieve the effect of simple operation, dense microstructure and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

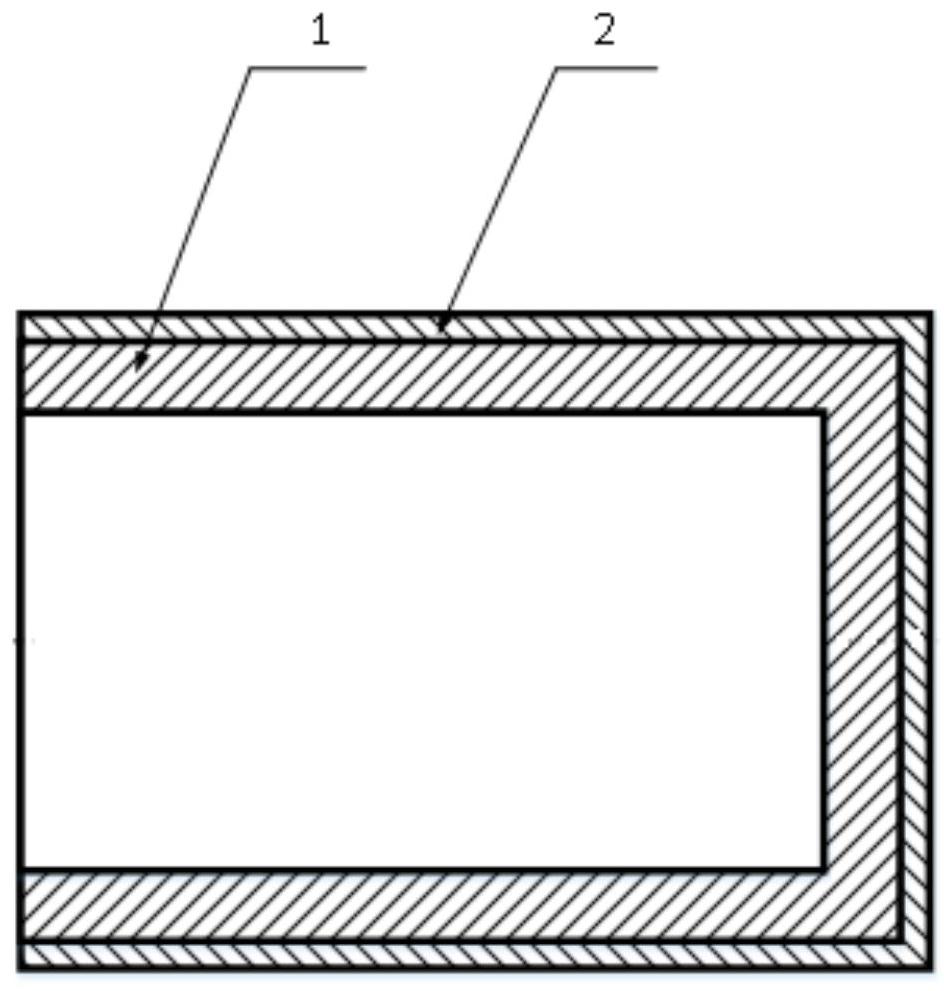

[0039] A composite bushing for sinking rollers manufactured by laser additive manufacturing in this embodiment, the bushing includes a sinking roller bushing body 1 and a wear-resistant and corrosion-resistant surface layer 2, and the wear-resistant and corrosion-resistant surface layer 2 is covered on the On the sinking roller bushing body 1.

[0040] Wherein, the chemical composition and mass fraction of the material of the sunken roller sleeve body 1 include 0.30%C, 22.83%Cr, 8.06%Ni, 0.06%Ce, 0.02%N, 5.79%Mo, 2.64%Al, 12.53% Nb, 3.21% Si, 0.41% Mn, 0.022% P, 0.019% S, the balance being Fe and other unavoidable impurities. The chemical composition and mass fraction of the material of the wear and corrosion resistant surface layer 2 include 18.03% B, 28.60% Cr, 16.45% Co, 10.66% W, 0.75% Y, 2.30% C and 23.21% Ni.

[0041] A method for preparing a composite shaft sleeve of a sinking roller manufactured by laser additive manufacturing in this embodiment includes the following...

Embodiment 2

[0046] A composite bushing for sinking rollers manufactured by laser additive manufacturing in this embodiment, the bushing includes a sinking roller bushing body 1 and a wear-resistant and corrosion-resistant surface layer 2, and the wear-resistant and corrosion-resistant surface layer 2 is covered on the On the sinking roller bushing body 1.

[0047] Wherein, the chemical composition and mass fraction of the material of the sunken roller sleeve body 1 include 0.43%C, 22.15%Cr, 8.51%Ni, 0.03%Ce, 0.05%N, 5.40%Mo, 2.88%Al, 12.18% Nb, 3.46% Si, 0.27% Mn, 0.021% P, 0.015% S, the balance being Fe and other unavoidable impurities. The chemical composition and mass fraction of the material of the wear-resistant and corrosion-resistant surface layer 2 include 18.77% B, 28.17% Cr, 16.51% Co, 9.75% W, 0.89% Y, 2.17% C and 23.74% Ni.

[0048] A method for preparing a composite shaft sleeve of a sinking roller manufactured by laser additive manufacturing in this embodiment includes the ...

Embodiment 3

[0053] A composite bushing for sinking rollers manufactured by laser additive manufacturing in this embodiment, the bushing includes a sinking roller bushing body 1 and a wear-resistant and corrosion-resistant surface layer 2, and the wear-resistant and corrosion-resistant surface layer 2 is covered on the On the sinking roller bushing body 1.

[0054] Wherein, the chemical composition and mass fraction of the material of the sunken roller bushing body 1 include 0.38%C, 22.60%Cr, 8.35%Ni, 0.05%Ce, 0.03%N, 5.61%Mo, 2.76%Al, 12.30% Nb, 3.29% Si, 0.34% Mn, 0.020% P, 0.017% S, the balance being Fe and other unavoidable impurities. The chemical composition and mass fraction of the material of the wear and corrosion resistant surface layer 2 include 18.08% B, 28.34% Cr, 16.92% Co, 10.12% W, 0.80% Y, 2.23% C and 23.51% Ni.

[0055] A method for preparing a composite shaft sleeve of a sinking roller manufactured by laser additive manufacturing in this embodiment includes the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com