A kind of preparation method of solid oxide fuel cell cathode current collector

A fuel cell cathode, solid oxide technology, applied in solid electrolyte fuel cells, fuel cell parts, fuel cells and other directions, can solve the problems of complex preparation process, achieve simple process, good high temperature toughness, good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of described current collector casting film, comprises the following steps:

[0041] A. Mix the current collector material with alcohol and methyl ethyl ketone solvent, triethanolamine dispersant, and ball mill to mix;

[0042] B. the mixed slurry of step A is equipped with dibutyl phthalate and polyvinyl alcohol plasticizer, polyvinyl butyral binder, graphite pore-forming agent and triethanolamine dispersant, and ball milling and mixing;

[0043] C. After sieving the slurry mixed in step B with a 60-80 mesh drying net and vacuum degassing treatment, cast it on the casting machine according to the required thickness and size;

[0044] D. Cut the dried biscuit into the required size, laminate and vacuum seal, and then carry out isostatic pressing.

[0045] The ball milling condition in step A is to use a planetary ball mill for 1-3 hours under the controllable condition of 0-50Nz.

[0046] The ball milling condition in step B is to use a planetar...

Embodiment 1

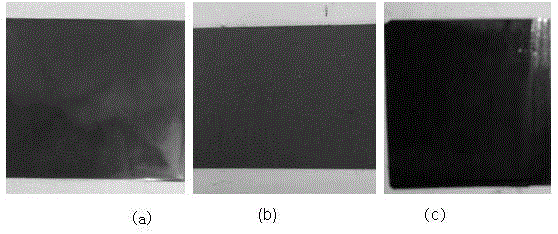

[0062] Preparation of SOFC cathode current collector green body

[0063] Weigh 25g cathode current collector material (such as: La 0.8 Sr 0.2 CoO 3 (LSC), La 0.8 Sr 0.2 MnO 3 (LSM) and (Mn,Co) 3 o 4 ), with alcohol and butanone (according to 1:1 mass ratio) mixed solvent, add triethanolamine dispersant, and then use planetary ball mill to mix ball ink under 50Nz (400 rpm) controllable conditions for 1 hour. Then add dibutyl phthalate and polyvinyl alcohol plasticizer, polyvinyl butyral binder, graphite pore-forming agent and triethanolamine dispersant, mix well by ball milling, and then use planetary ball milling The ball mill was mixed for 2 hours under the controllable condition of 50Nz (400 rpm). After sieving through a 60-mesh screen and vacuum degassing treatment, it is cast on a tape casting machine. The casting film was dried at 50°C for 1 hour, cut into the required size, laminated and hot pressed at 75°C under a pressure of 10-12MPa to obtain the desired gree...

Embodiment 2

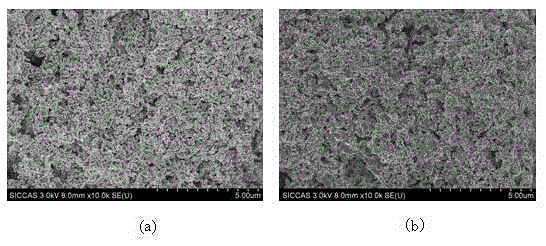

[0065] Weigh 50gLSC, 50g(Mn,Co) 3 o 4 , after preparing the current collector green body according to the steps of Example 1, it was assembled on the cathode of the battery. After heating at a rate of 1 °C / min to 600 °C for 2 hours, and then at a rate of 2 °C / min to 850 °C for 1 hour, the battery cathode current collector is formed in situ. image 3 where a and b are LSC and (Mn,Co) respectively 3 o 4 SEM images of current collectors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com