Continuous Mo fiber reinforcement TiAl base composite material and method for preparing same

A composite material and fiber-reinforced technology, which is applied in the field of composite materials and its preparation, can solve the problems of poor room temperature toughness, complex preparation methods, and insufficient strength of TiAl alloys, and achieve the effects of simple operation, improved efficiency, and improved performance of TiAl alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

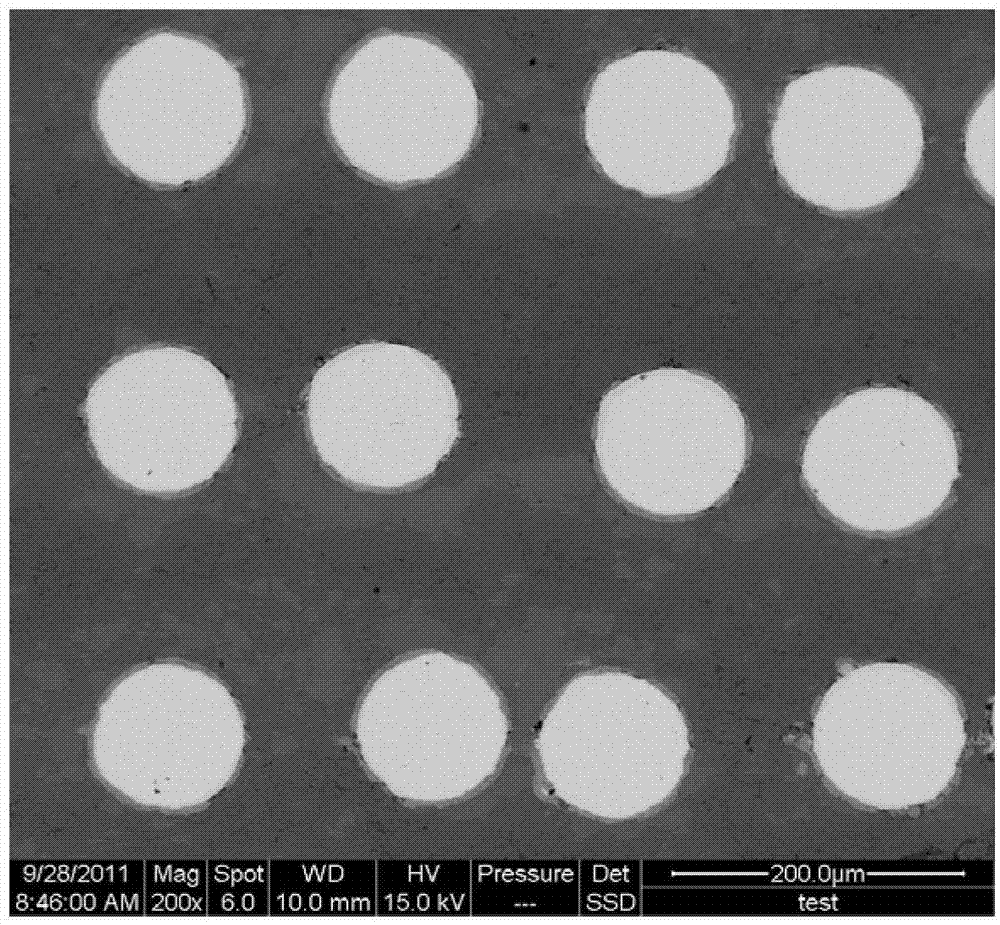

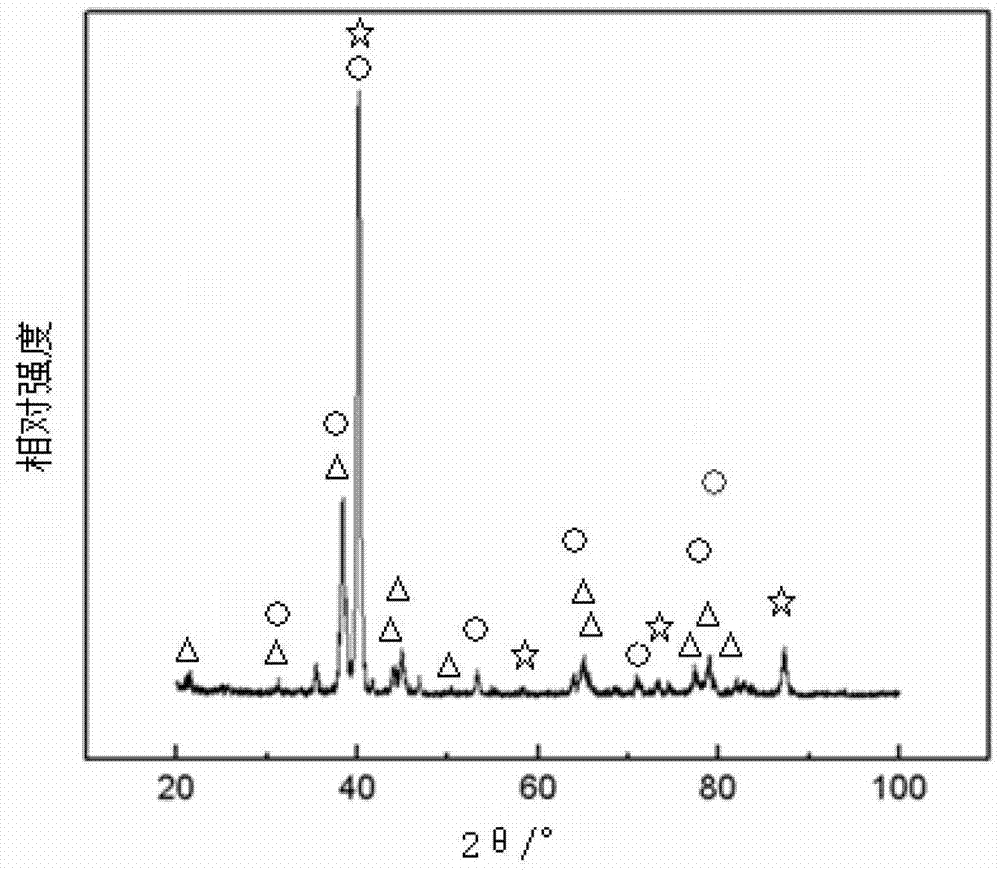

[0017] Specific embodiment one: a kind of continuous Mo fiber reinforced TiAl matrix composite material of this embodiment is characterized in that continuous Mo fiber reinforced TiAl matrix composite material is made up of continuous Mo fiber reinforcement phase and TiAl matrix; Wherein, the volume percentage of Mo fiber 10-50vol.%; the molar ratio of Ti element to Al element in the TiAl matrix is 1-1.5:1.

specific Embodiment approach 2

[0018] Specific embodiment two: the preparation method of a kind of continuous Mo fiber reinforced TiAl-based composite material of this embodiment is carried out according to the following steps:

[0019] 1. Weigh 1 part of polymethyl methacrylate, 4 to 10 parts of mixed powder of Ti powder and Al powder in parts by mass; wherein, the molar ratio of Ti powder to Al powder is 1 to 1.5:1;

[0020] 2. Add the polymethyl methacrylate weighed in step 1 into acetone, stir and dissolve, and prepare a polymethyl methacrylate acetone solution with a mass percentage of polymethyl methacrylate of 15.3% to 20.2%, and then Add the mixed powder of Ti powder and Al powder weighed in step 1 and continue to stir until a uniform suspension is formed to obtain a powder slurry;

[0021] 3. Using a fiber winding machine, with the aluminum plate as the carrier, the Mo fiber is wound on the aluminum plate at a distance of 0.12-0.3mm, and the powder slurry obtained in step 2 is coated on it, and the...

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, take 1 part of polymethyl methacrylate by mass fraction, the mixed powder of 6 parts of Ti powder and Al powder; Wherein, The molar ratio of Ti powder to Al powder is 53:47. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com