Sewage pipeline construction process

A sewage pipeline and construction technology technology, applied in the sewer pipeline system, waterway system, pipeline laying and maintenance, etc., can solve the problems of enlargement, influence of pipe jacking construction process, etc., to improve the bonding strength, not easily affected, improve The effect of the lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

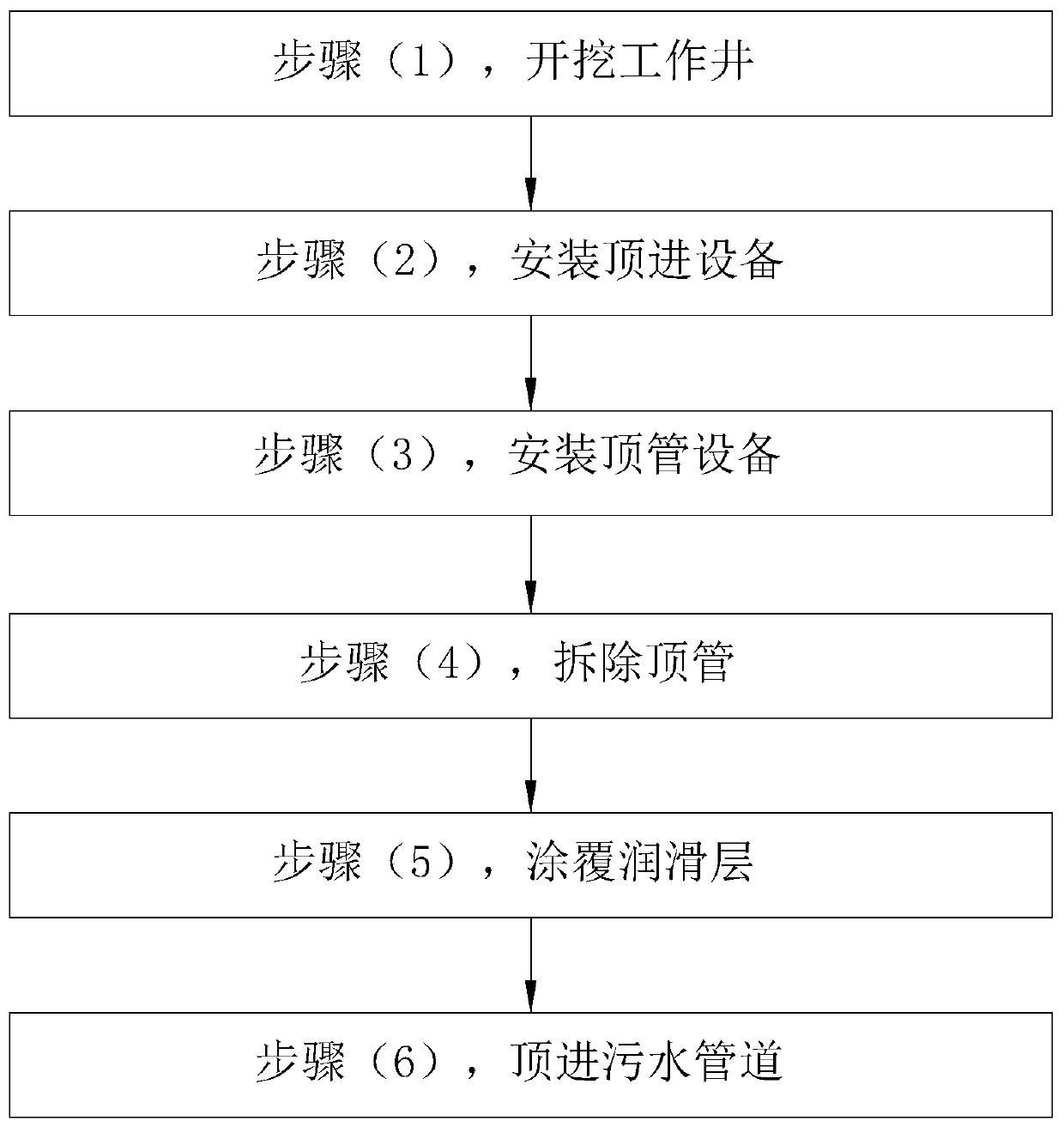

[0070] refer to figure 1 , is a kind of sewage pipeline construction technique disclosed by the present invention, comprising the following steps:

[0071] Step (1), digging working well, specifically as follows:

[0072] Determine the laying position of the sewage pipeline according to the design drawings, and excavate several working wells in the length direction of the sewage pipeline, and control the distance between adjacent working wells to be 50m.

[0073] Step (2), install jacking equipment, details are as follows:

[0074] First fix the jacking equipment on one side of the working well, and then fix the base on the bottom wall of the working well, and the base is close to the side opposite the working well and the jacking equipment, and is used for the sewage pipeline during the jacking process. Pre-positioning.

[0075] Step (3), install the pipe jacking equipment, as follows:

[0076] Install the pipe jacking machine on the base first, then install the pipe jack...

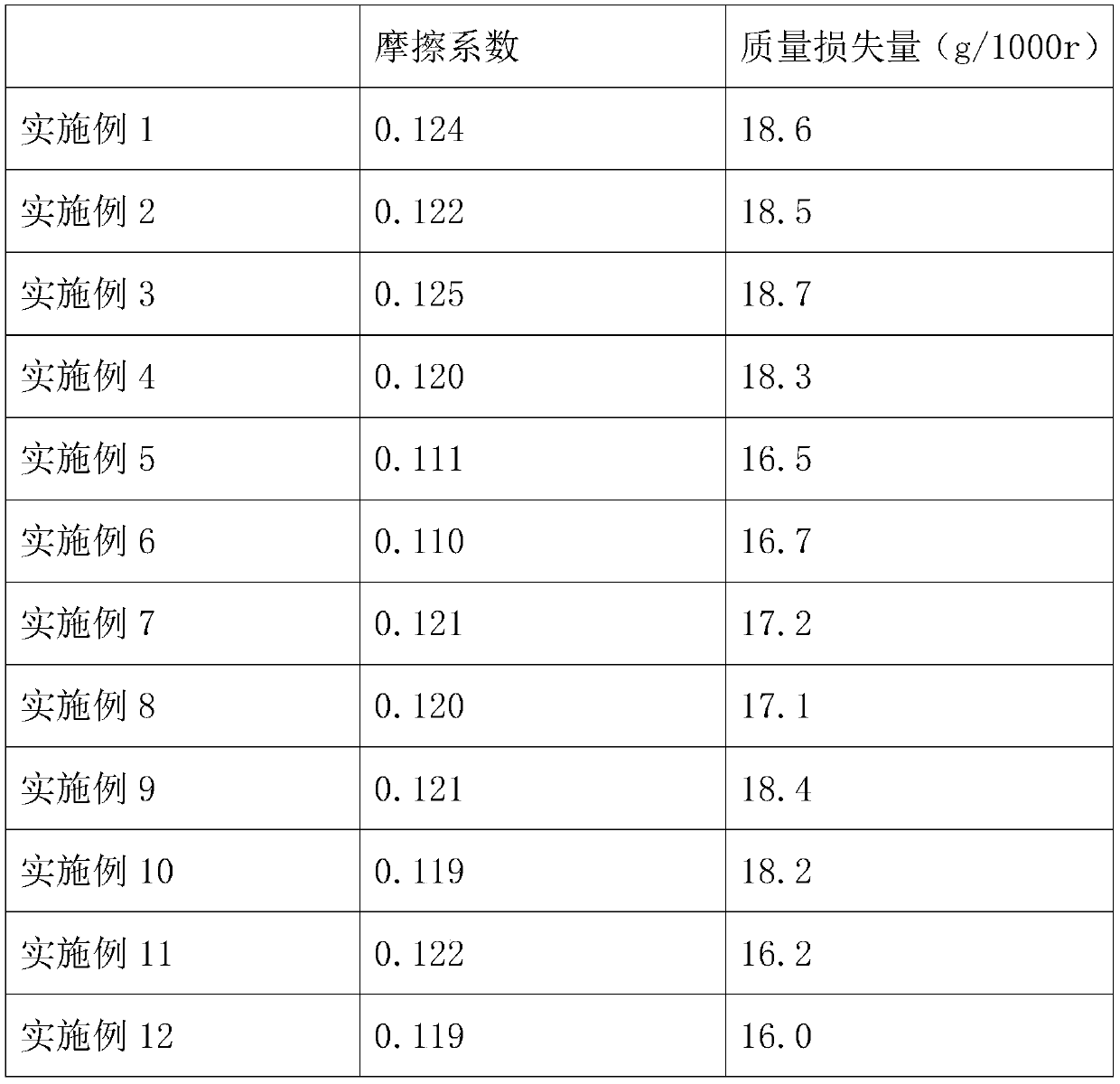

Embodiment 2

[0085] The difference with embodiment 1 is:

[0086] The consumption of each component that adds in the step (5) is as follows:

[0087] Sodium stearate 52.5kg; acrylic acid emulsion 30kg; water 15kg; sodium hexametaphosphate 2kg; polyvinyl alcohol 1.25kg; oleic acid 1.5kg.

Embodiment 3

[0089] The difference with embodiment 1 is:

[0090] The consumption of each component that adds in the step (5) is as follows:

[0091] Sodium stearate 55kg; acrylic acid emulsion 32.5kg; water 10kg; sodium hexametaphosphate 3kg; polyvinyl alcohol 1kg; oleic acid 1kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com