Material yard windshield and dust suppression wall and construction method

A wind and dust suppression wall, construction method technology, applied in separation methods, building structures, chemical instruments and methods, etc. Loss of kinetic energy and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

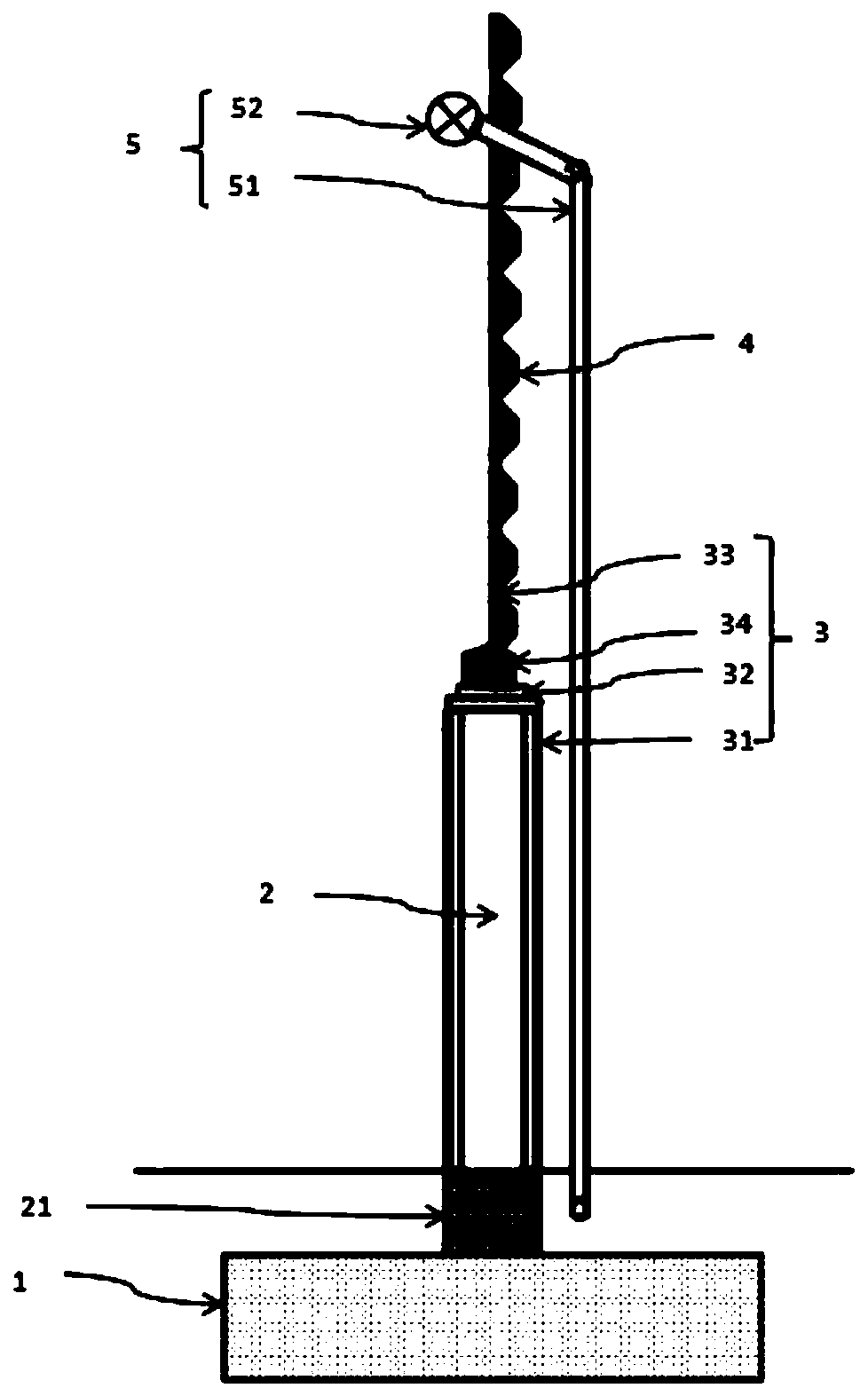

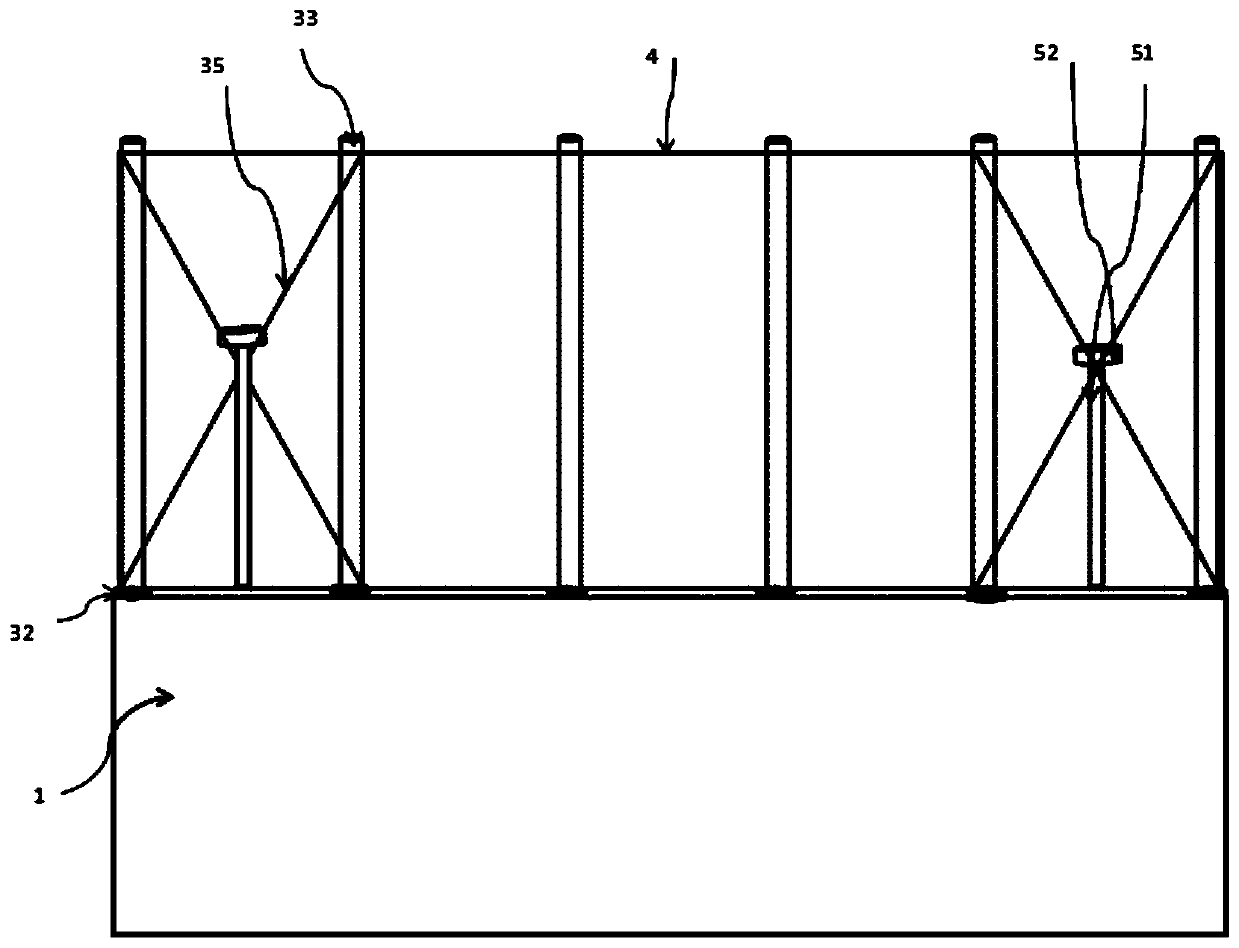

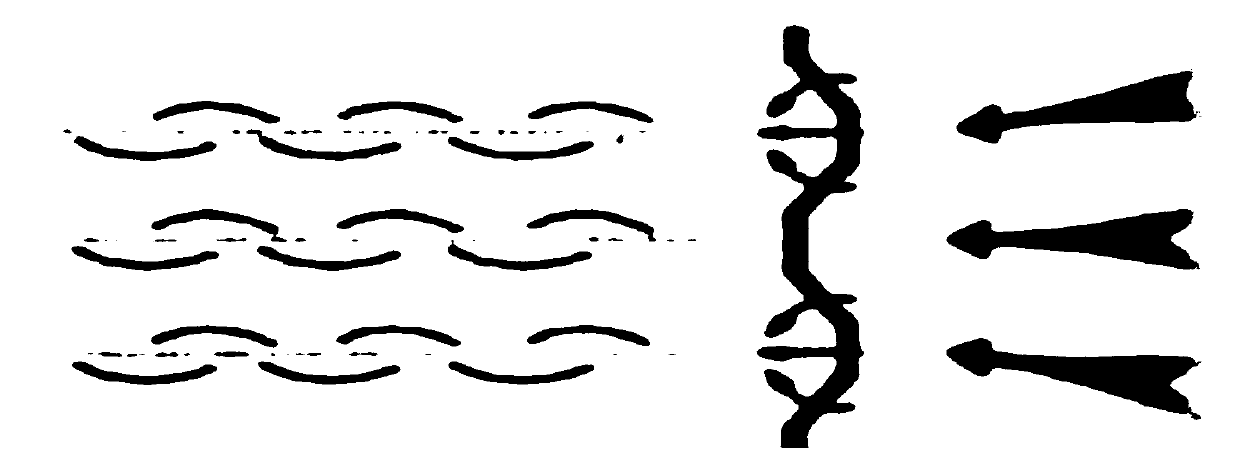

[0027] See attached figure 1 and 2 , a wind and dust suppression wall in a stockyard, the wind and dust suppression wall is composed of a foundation cushion, a wind protection wall, a steel structure support for a wind deflector, a wind deflector and a spraying device, and the specification of the foundation cushion is It is 200×1.2×0.3 meters, and it is set in the foundation cushion groove 0.5 meters below the ground; the windbreak wall adopts C30 reinforced concrete to pre-embed the windbreak wall reinforcement and windbreak wall on the foundation cushion The steel structure foundation on the upper part of the steel bar is poured as a whole windshield wall; the steel structure support of the windshield is installed on the windshield wall; the windshield is installed on the steel structure support of the windshield; The sprinkler device includes sprinkler pipes and spray guns, the sprinkler pipes are buried between the foundation cushion and the ground along the direction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com