Intelligent drying system

A technology of drying system and conveyor belt, which is applied in the direction of drying solid materials, dry cargo handling, drying, etc., which can solve the problems of uneven drying and different drying degrees, and achieve the goal of improving drying effect, reducing humidity, and improving dispersing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

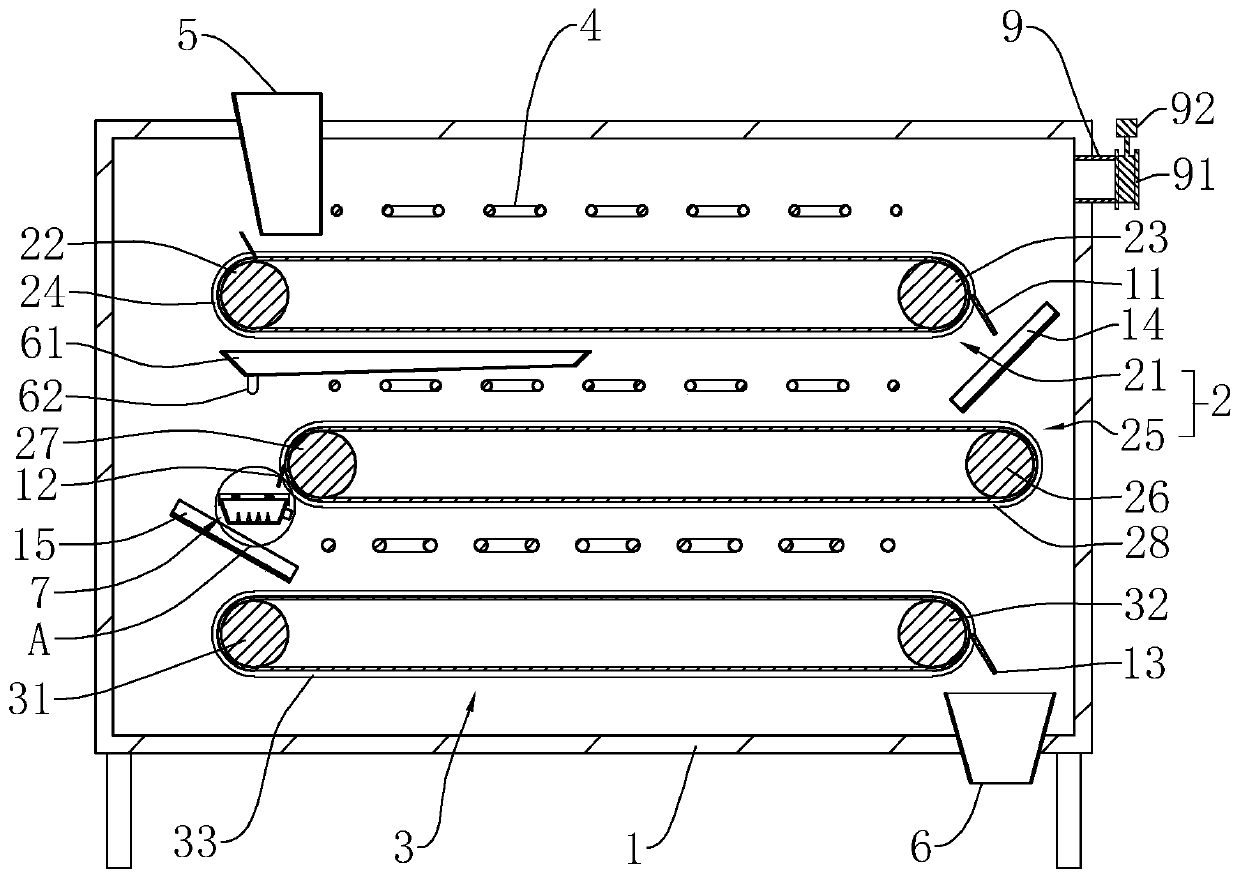

[0037] refer to figure 1 , is an intelligent drying system disclosed in the present invention, comprising a box body 1, in which a first conveyor belt 2, a second conveyor belt 3, a heating pipe 4, a feed hopper 5, a discharge hopper 6 and a separation mechanism 7 are arranged. . The feeding hopper 5 is fixed on the top of the box body 1 , and the feeding hopper 5 is located above the feeding end of the first conveyor belt 2 . The feed end of the second conveyor belt 3 is located below the discharge end of the first conveyor belt 2 , and the separation mechanism 7 is close to the discharge end of the first conveyor belt 2 . The discharge hopper 6 is fixed on the bottom of the box body 1 , and the discharge hopper 6 is located below the discharge end of the second conveyor belt 3 .

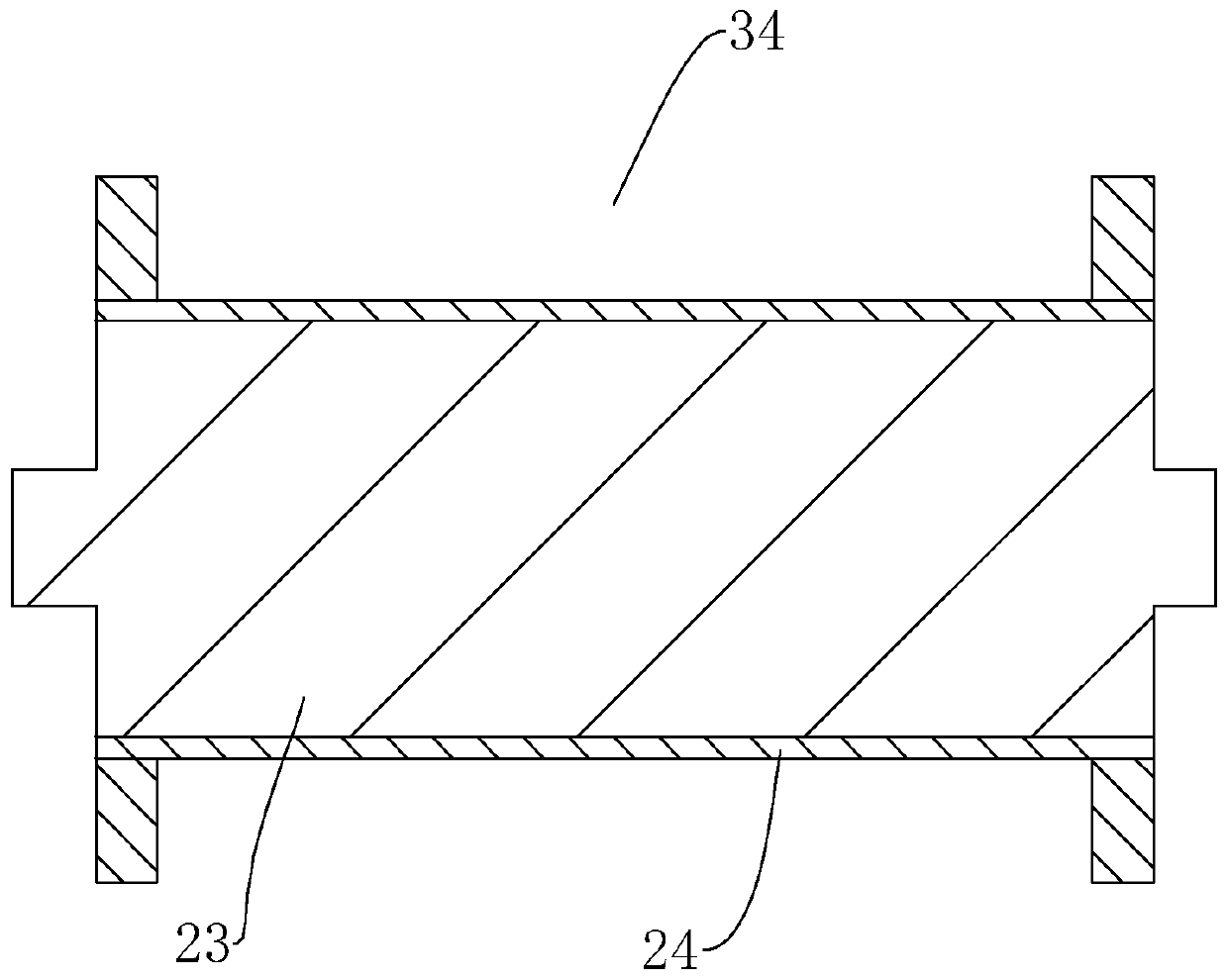

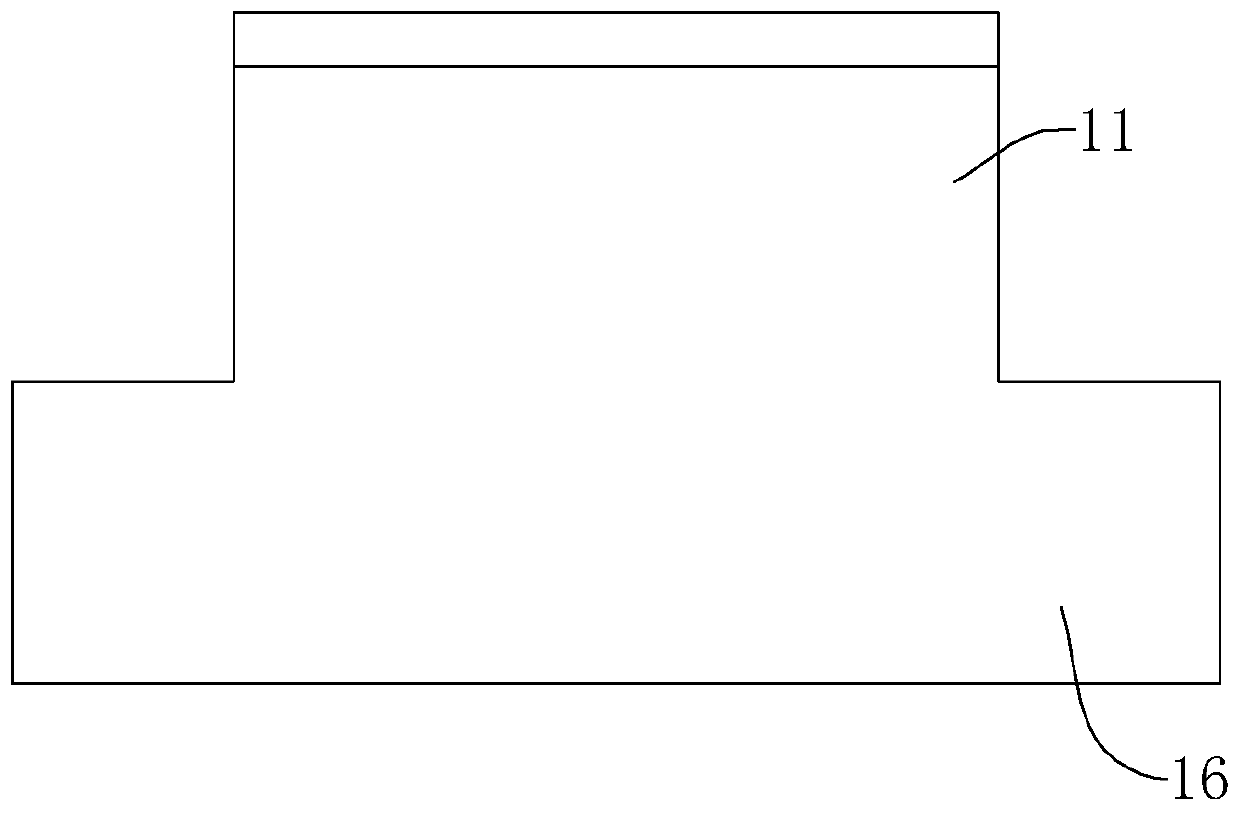

[0038] The first conveyer belt 2 comprises conveyer belt one 21 and convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com