Preparation method of interdigital electrode

A technology of interdigitated electrodes and carbon layers, which is applied to electrical components, impedance networks, etc., can solve the problems of large metal wires, poor adhesion, and collapsed patterns, so as to improve adhesion, improve molding accuracy and quality, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

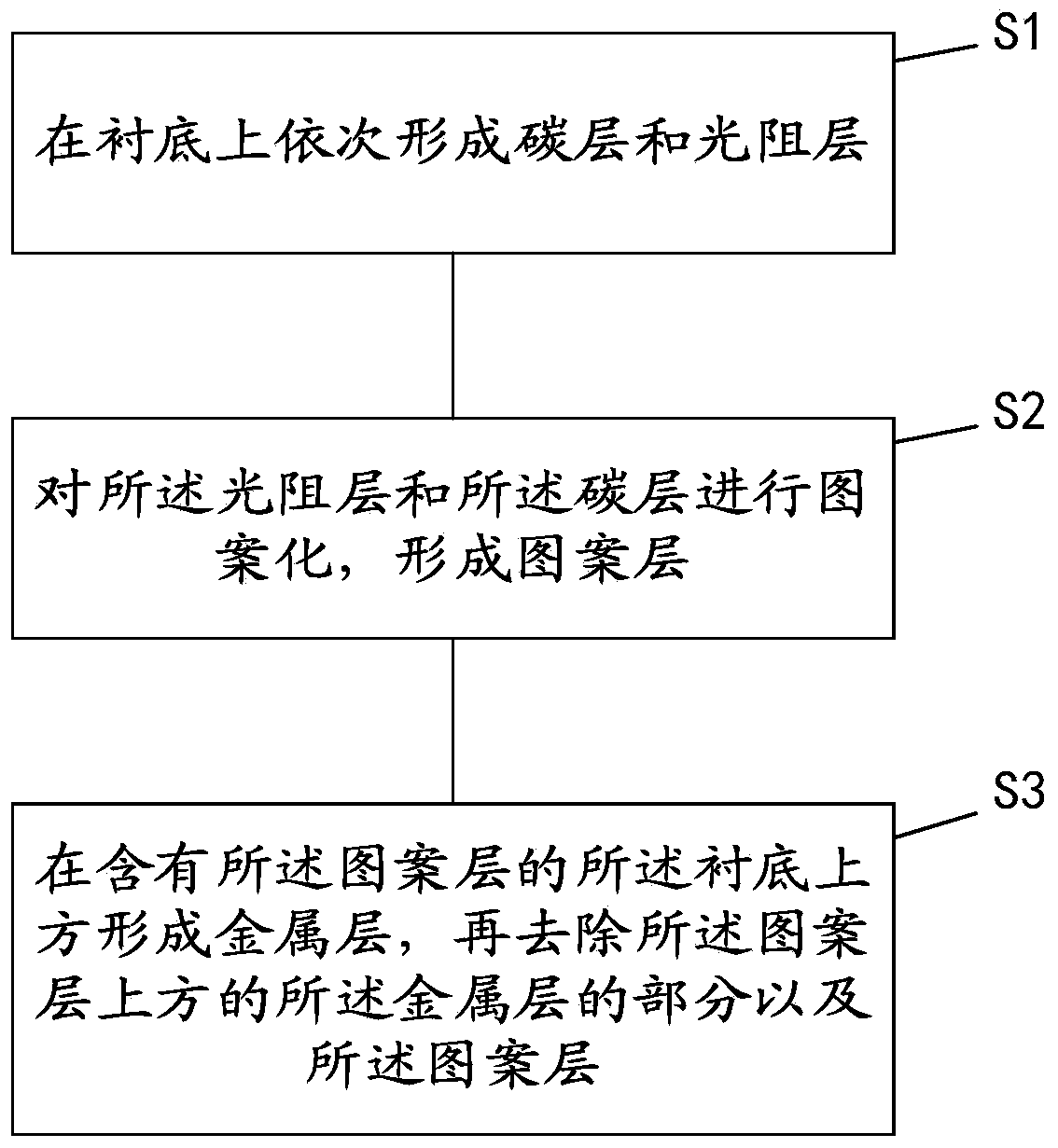

[0055] see figure 1 , the present embodiment provides a method for preparing an interdigitated electrode, comprising the following steps:

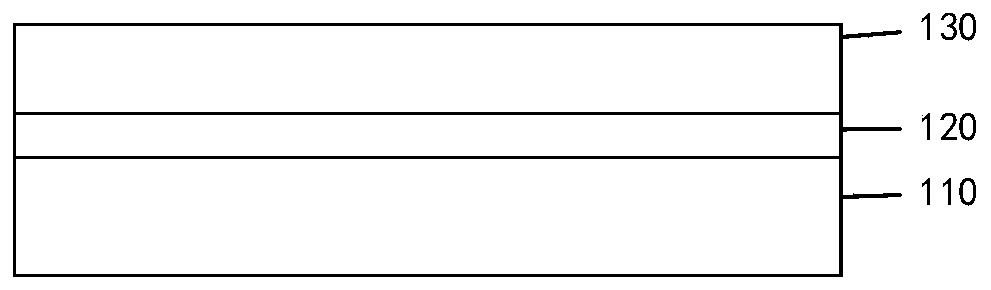

[0056] S1: see figure 2 , forming a carbon layer 120 and a photoresist layer 130 sequentially on the substrate 110 .

[0057] Wherein, the substrate 110 is made of lithium niobate or lithium tantalate. The carbon layer 120 may be formed on the substrate 110 by sputtering at a temperature below 100 degrees Celsius. The thickness of the carbon layer 120 is not less than the thickness of the required metal wire, preferably 300-3000.

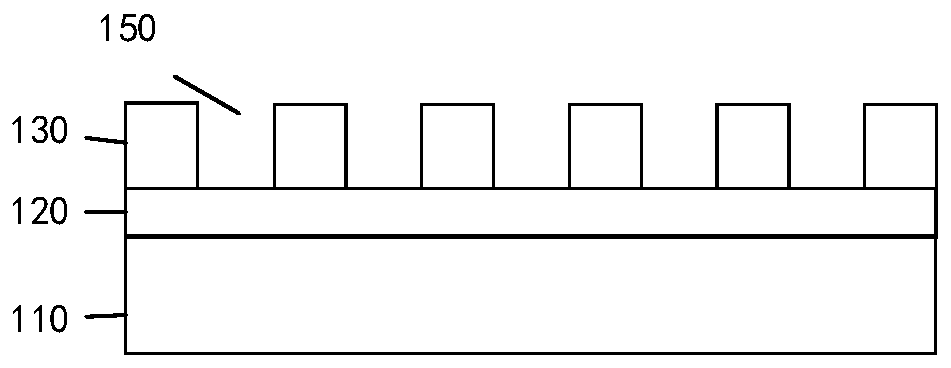

[0058] S2: see Figure 3 to Figure 5 , patterning the photoresist layer 130 and the carbon layer 120 to form a patterned layer 180 .

[0059] Specifically, firstly, the photoresist layer 130 is exposed and developed to form a plurality of spaced hollow areas 150 on the photoresist layer 130 . The width of the hollow area 150 is equal to the line width of the required metal line 170 . The bottom of the ho...

no. 2 example

[0071] see Image 6 , the present embodiment provides a method for preparing an interdigitated electrode, comprising the following steps:

[0072] S21: See Figure 7 , forming the metal layer 140 on the substrate 110 .

[0073] Wherein, the metal layer 140 is a preliminary material for forming the required metal wire 170, and the thickness of the metal layer 140 is equal to the thickness of the required metal wire 170. The metal layer 140 can be made of aluminum and formed by evaporation.

[0074] S22: sequentially forming a carbon layer 120 and a photoresist layer 130 on the metal layer 140 .

[0075] Wherein, the carbon layer 120 is used as an anti-reflection layer, and can also improve the adhesion of the photoresist layer 130 .

[0076] S23: See Figure 8 , exposing and developing the photoresist layer 130 to form a plurality of spaced hollow areas 150 on the photoresist layer 130 .

[0077] Wherein, forming a plurality of spaced hollow areas 150 on the photoresist la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com