A device and method for accurately preparing cooling holes of turbine blades by picosecond laser

A cooling hole and ultra-fast laser technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of expensive, difficult to apply, high operation and maintenance costs, and achieve low maintenance and use costs, high processing quality, The effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

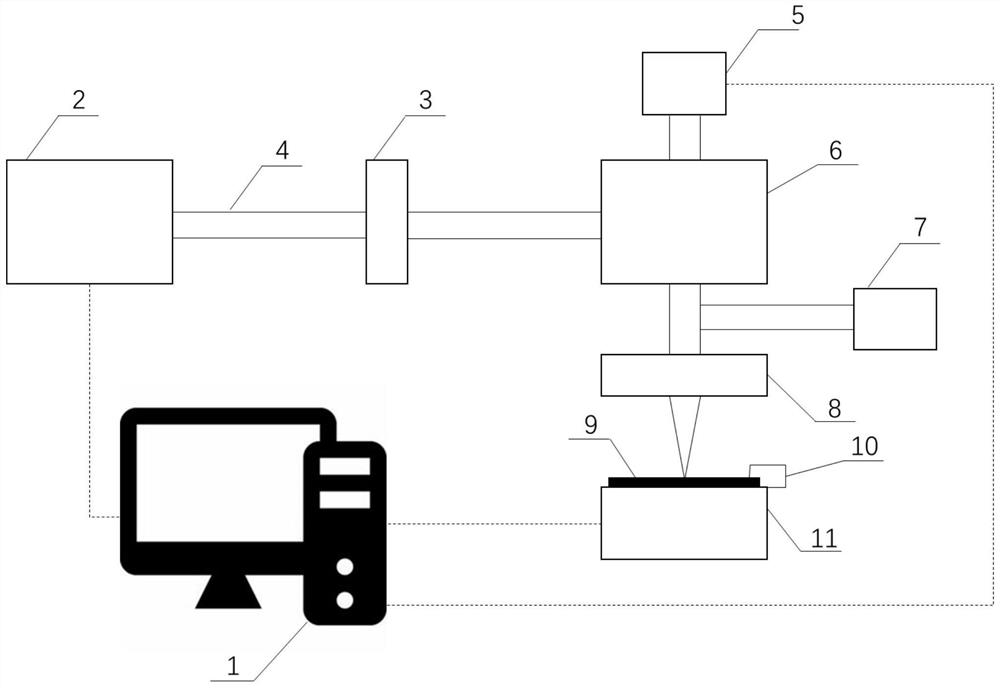

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0032] The invention involves the use of a fixed laser beam, a six-position translation platform to clamp the workpiece to be processed, CCD real-time monitoring and feedback, according to different material types and processing requirements, the use of corresponding processing methods and process parameters, and the realization of the process through integrated programming software A high-quality and high-efficiency gas film hole preparation method and device for controlled automatic processing.

[0033] Specifically, it can be achieved by the following methods:

[0034] Step 1. Perform equipment attribute selection and performance debugging according to the material type of the workpiece to be processed; program writing and software setting according to the parameters of the gas film hole to be processed;

[0035] Step 2: Directly irradiate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com