A machine-controlled annular multi-node welding device and its welding method

A welding device and multi-node technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of affecting the welding efficiency of curved workpieces, increasing the welding cost of workpieces, wasting time, etc., so as to increase welding efficiency and reduce welding costs. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

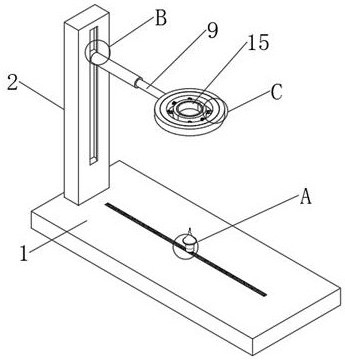

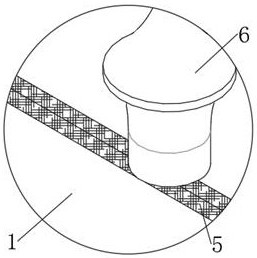

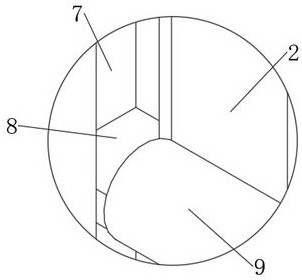

[0035] see Figure 1-5, a machine-controlled ring-shaped multi-node welding device, including a base 1 and a lifting platform 2, and the lifting platform 2 is fixedly connected to the base 1, and a translational electric chute 3 is dug on the base 1, and the translational electric chute 3 is Slidingly connected with a translational electric slider 4, the upper end of the translational electric slider 4 is fixedly connected with a welding nozzle 6, and a lifting electric chute 7 is excavated on the lifting table 2, and a lifting slider 8 is slidingly connected in the lifting electric chute 7, and the lifting Slide block 8 is fixedly connected with electric telescopic rod 9 at one end far away from lifting electric chute 7 slot bottom plates, and the end of electric telescopic rod 9 far away from lifting slide block 8 is fixedly connected with outer fixed frame 10, and is connected with itself in the outer fixed frame 10. The matching inner rotating frame 11, the inner rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com