Breaking-up and assembling system and method for bogie

An assembly system and bogie technology, applied in the field of assembly system and bogie decomposition, can solve the problems of high labor intensity, scattered work stations, hidden dangers of safe operation, etc., and achieve the effect of improving transfer efficiency and good restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

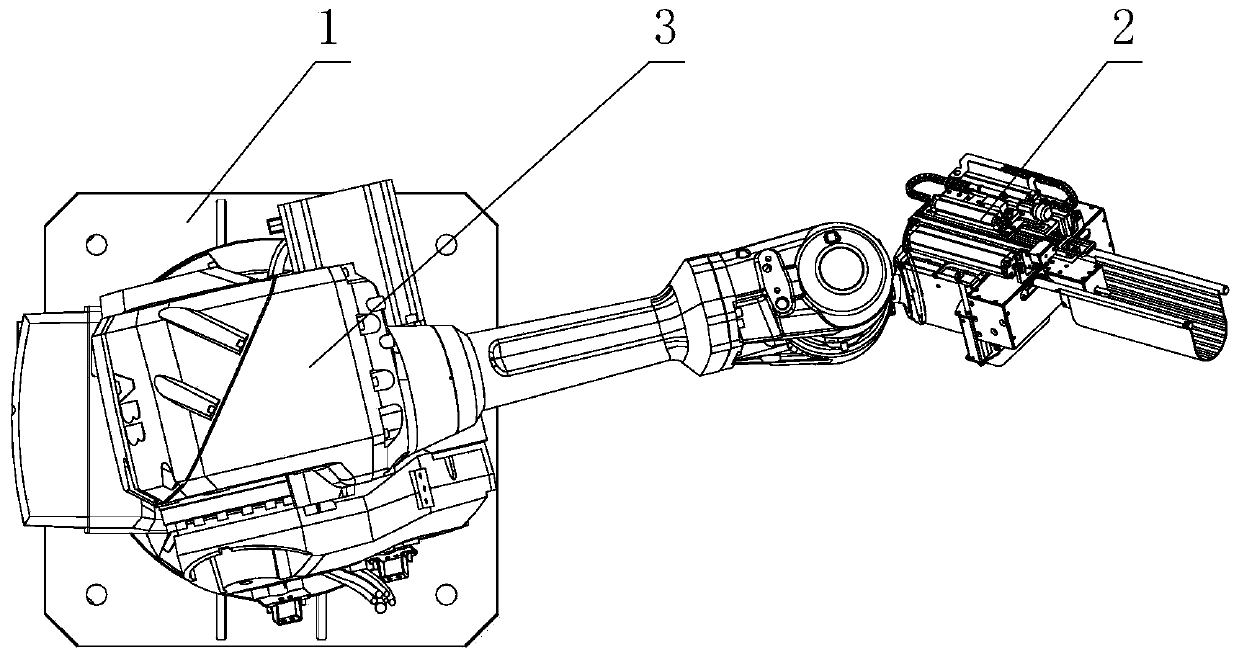

[0049] Embodiment 1: as Figure 1 to Figure 4 As shown, a bogie disassembly and assembly system, the disassembly and assembly system includes a disassembly system for realizing bogie disassembly, an assembly system for realizing bogie assembly, and also includes a A conveyor belt 18, the material input end of the conveyor belt 18 is connected to the part output end of the disassembly system, and the material output end of the conveyor belt 18 is connected to the part receiving end of the assembly system;

[0050] It also includes a detection and sorting station, which is set on the material transfer path between the part output end of the disassembly system and the part receiving end of the assembly system.

[0051] When this scheme is used in practice, the purpose of bogie disassembly and assembly can be achieved through the following methods, that is, a specific bogie disassembly and assembly method based on the above system is provided as follows:

[0052] S1. Complete the...

Embodiment 2

[0068] The present embodiment is further limited on the basis of embodiment 1:

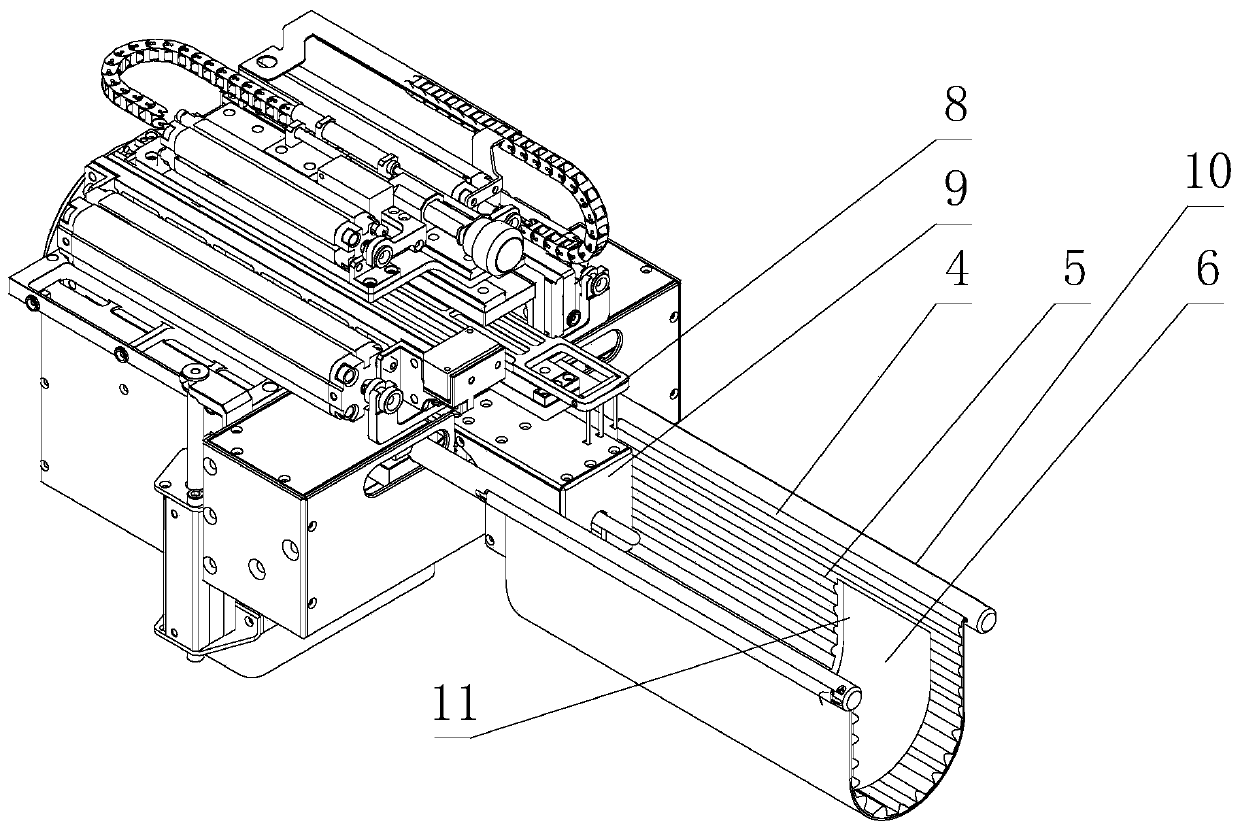

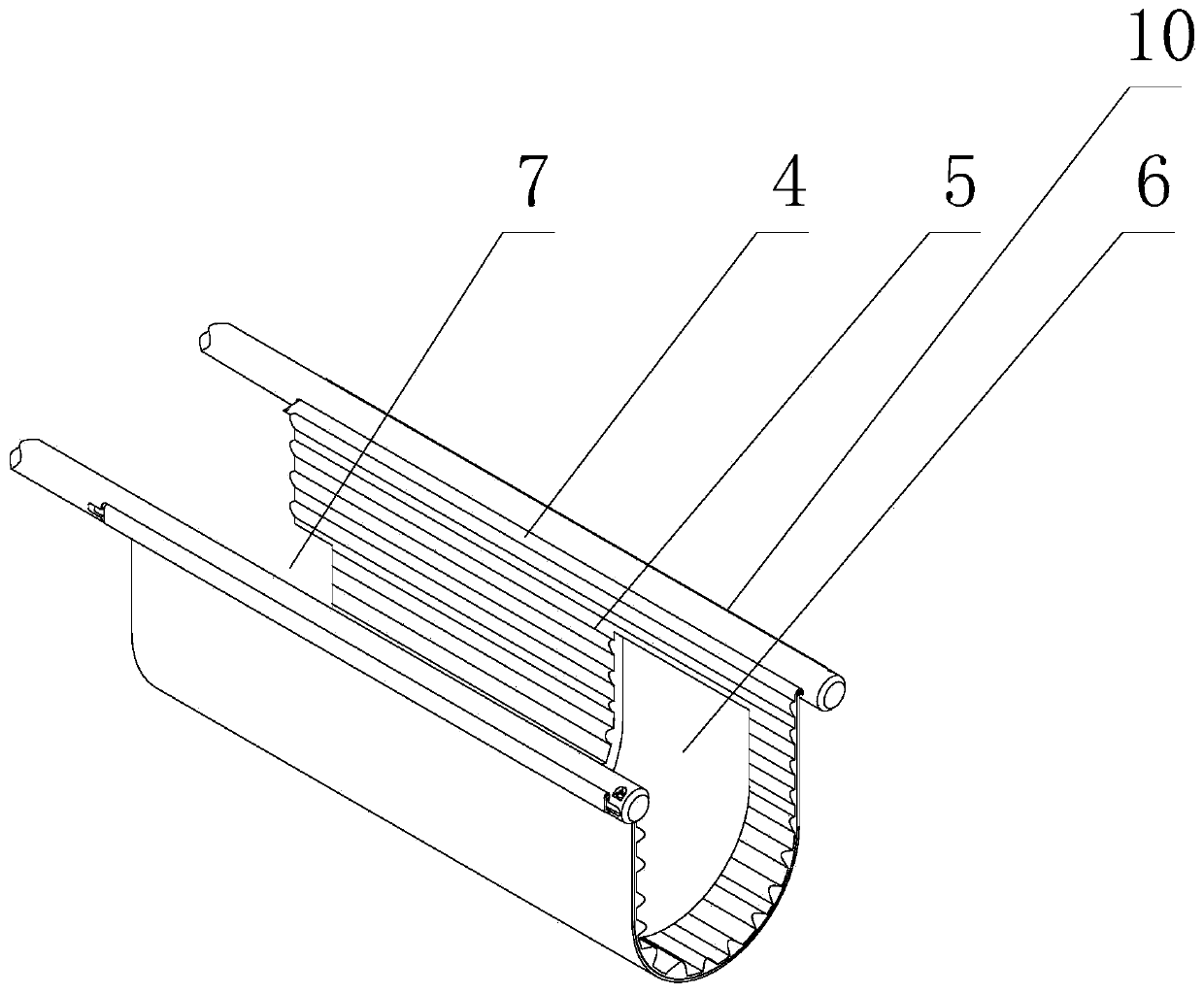

[0069] Such as Figure 1 to Figure 4 As shown, the disassembly manipulator 12 includes a manipulator body 1, and also includes a gripping part 2 arranged on the action end of the manipulator body 1, and the gripping part 2 includes two cantilever rods 10, a pocket for providing a pocket-like space body 4, each side of the pocket body 4 is fixed on the cantilever rod 10, and also includes a rib 5 arranged on the pocket body 4, and the rib 5 is convex outward relative to the inner surface of the pocket body 4 space The ribs 5 are made of elastic material: when the ribs 5 are squeezed outside the bogie bolster spring, the compressed ribs 5 are partially elastically deformed.

[0070] In the prior art, for bogie disassembly, there is a technical solution such as that provided by the invention patent document with application number CN201822272546.9, and the adoption of this solution is conducive to r...

Embodiment 3

[0083] Such as Figure 1 to Figure 3 As shown, this embodiment is further limited on the basis of Embodiment 1: in the prior art, in the process of realizing the mechanized disassembly and assembly of the bogie, since the wedge is taken out by the dismantling unit, its bottom is supported on the dismantling unit. On the unit, it is not convenient to use the pocket body 4 to realize the position transfer of the wedge in this state. To solve the above problems, it is set as follows: the manipulator body 1 also includes a rotary joint 3, and the rotary joint 3 can drive the gripping part 2 to generate Greater than or equal to 180° of rotation, and can drive the clamping part 2 to rotate: the notch 11 of the pocket-shaped space on the pocket body 4 faces upwards, and the notch 11 of the pocket-shaped space on the pocket body 4 faces downward. In actual use, the upward state of the notch 11 can be used for the pillow spring topple over and be introduced into the pocket-shaped space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com