Cap structure for fragile bottles

一种碎瓶、盖体的技术,应用在易碎瓶体的盖体结构领域,能够解决增加罹癌危险、溶出至内容物、焚化毒气等问题,达到提高卫生与安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

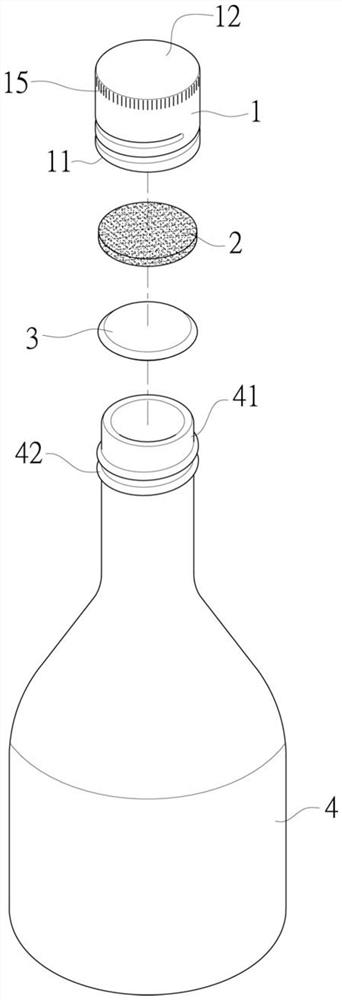

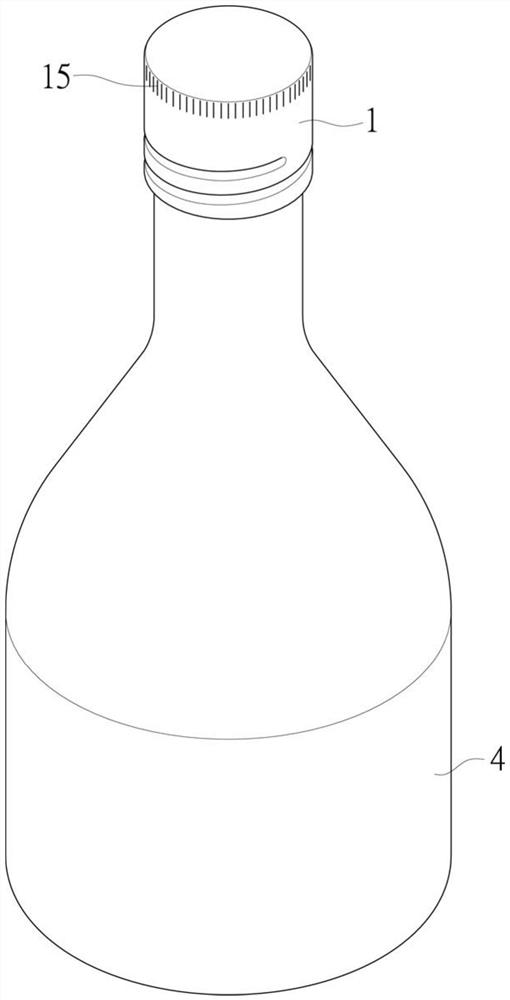

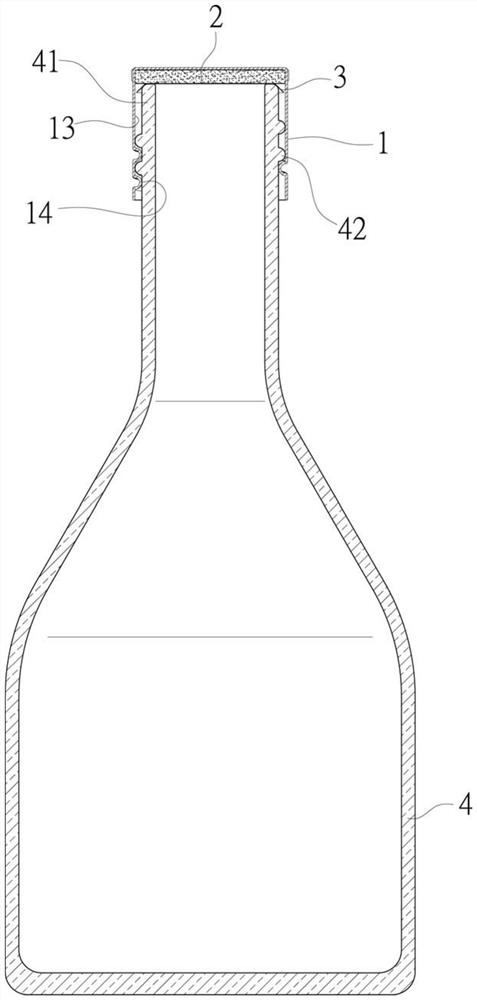

[0035] In order to make the technical means of the present invention and the technical effects that can be achieved more completely and clearly disclosed, please refer to the accompanying drawings and the labels as shown, and the detailed description is as follows:

[0036] First, see Figure 1 ~ Figure 3 Shown, be the cap body structure of fragile bottle body of the present invention, comprise:

[0037] A cover body 1, the cover body 1 can be made of metal materials such as stainless steel, please refer to Figure 4 As shown, the opposite ends of the cover main body 1 are respectively an open end 11 and a closed end 12, and the inside of the cover main body 1 forms a hollow covering cavity 13, and the opening of the covering cavity 13 is located at the open end 11, The cavity roof of the covering cavity 13 is located at the closed end 12, and the surrounding surface of the covering cavity 13 between the mouth of the cavity and the cavity roof forms the cavity wall of the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com