An anti-shock sliding spindle device

A main shaft device and impact-resistant technology, applied to rotating parts, shafts, bearings and other directions that resist centrifugal force, can solve the problems of poor impact resistance of the main shaft, fragile edges of ceramic parts, difficult processing of ceramic parts, etc. Longevity, the effect of avoiding machining difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

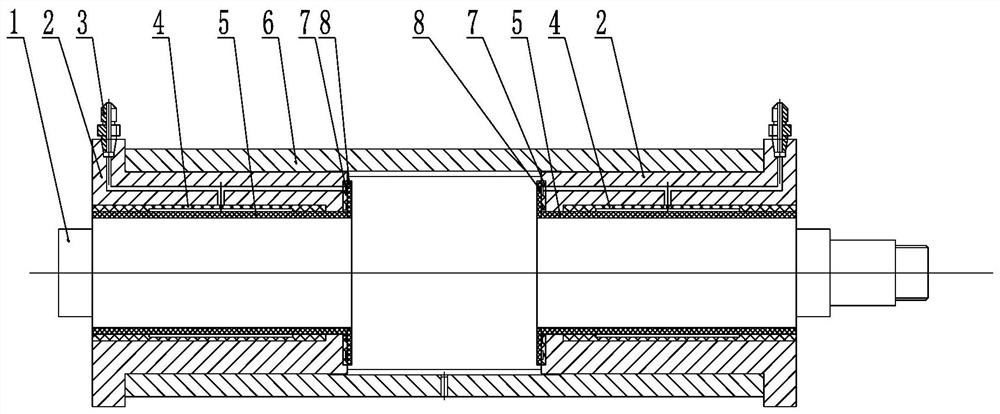

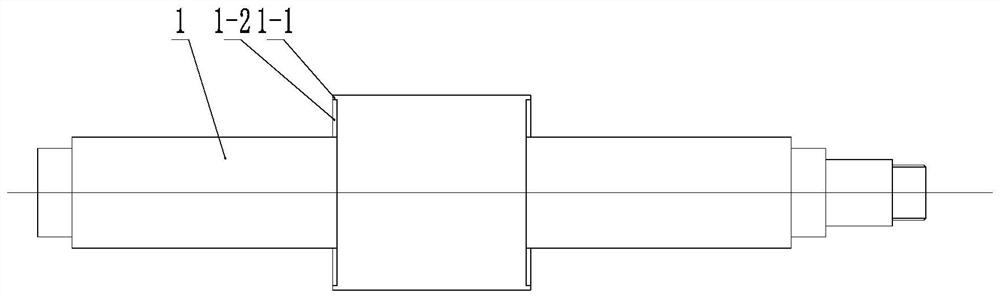

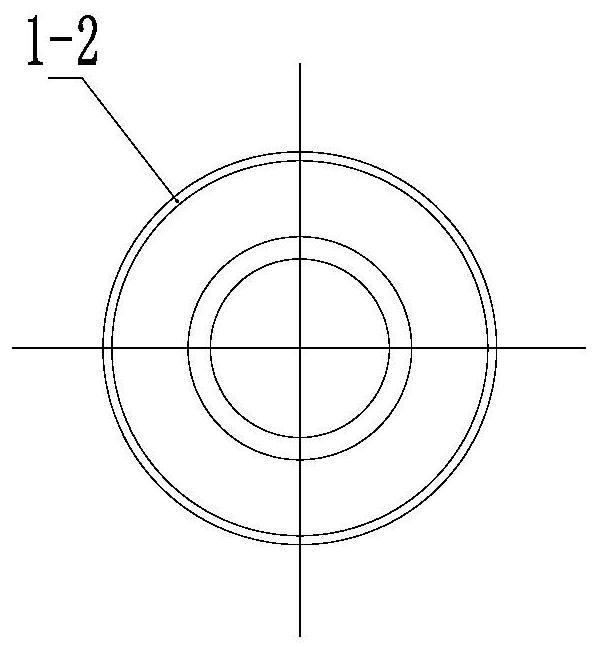

[0033] In order to solve the problems of poor wear resistance and high thermal expansion coefficient of the traditional spindle-bearing metal friction pair, an impact-resistant sliding spindle device is provided in this embodiment, using the shaft core 1 and the bearing bush bush 2 to pair all the bushes and bearing bushes The all-inclusive structure design avoids sudden changes in the shape of ceramic parts; at the same time, the bushing is made of ceramic material, and the bearing bush is made of polyether ether ketone or polyether ether ketone-based composite material. The friction pair formed by the two has excellent impact resistance, friction resistance and wear resistance , and can adapt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com