Microscopic differential reflectance spectroscopy measurement system and method for measuring thickness of nano film

A differential reflection and spectral measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problem of not having the ability to measure differential reflection signals in microscopic or micro-area, and achieve reduction of measurement errors, simple optical path structure, and expansion. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

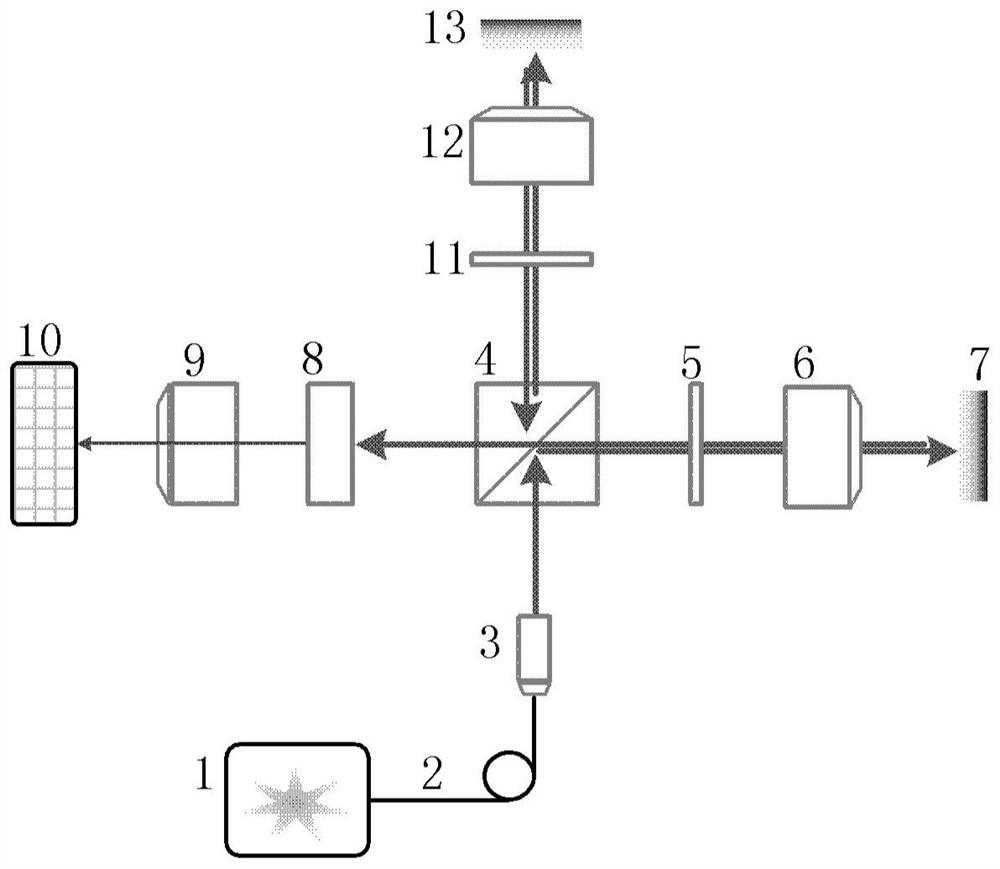

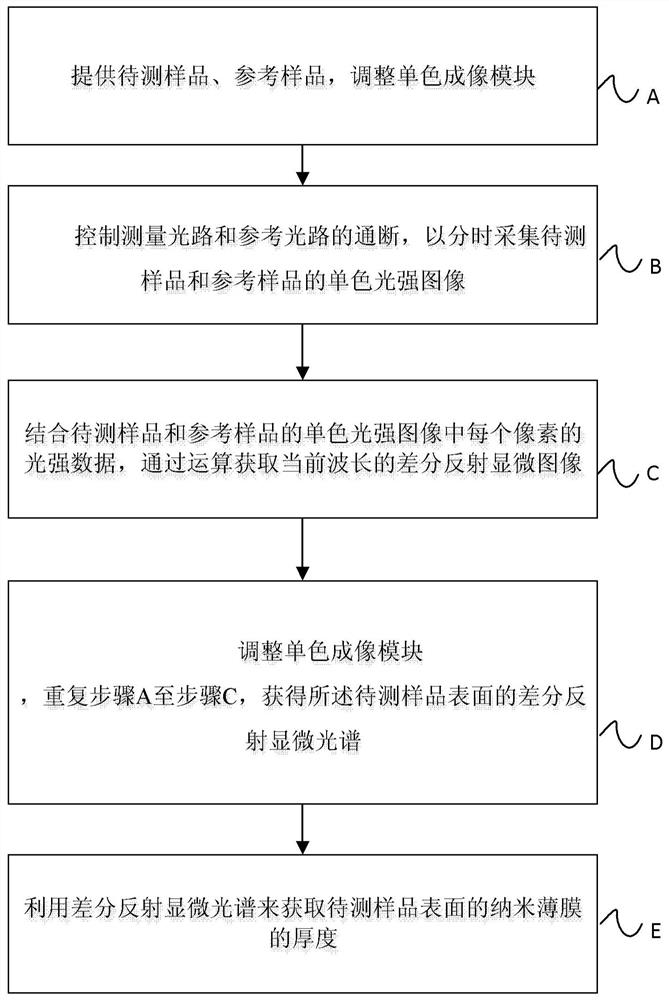

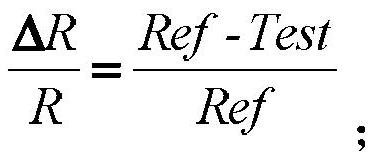

[0032] The invention provides a microscopic differential reflection spectrum measurement system and method for measuring the thickness of a nanometer film. The light output by the light source is respectively entered into the measurement optical path and the reference optical path through a beam splitter, and the samples to be measured and the reference samples are measured respectively. The real-time measurement of light intensity drift can be realized, the measurement error can be effectively reduced, and the microscopic spectrum measurement of the sample to be tested and the reference sample can be realized through the design of the measurement optical path and the reference optical path.

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0034] Certain embodiments of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com