Mars wind tunnel with sand and dust simulation

A wind tunnel, sand and dust technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve the problems that it is difficult to ensure the uniformity of sand and dust distribution in the test section, and cannot realize high wind speed simulation, so as to improve the boundary layer The effect of blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

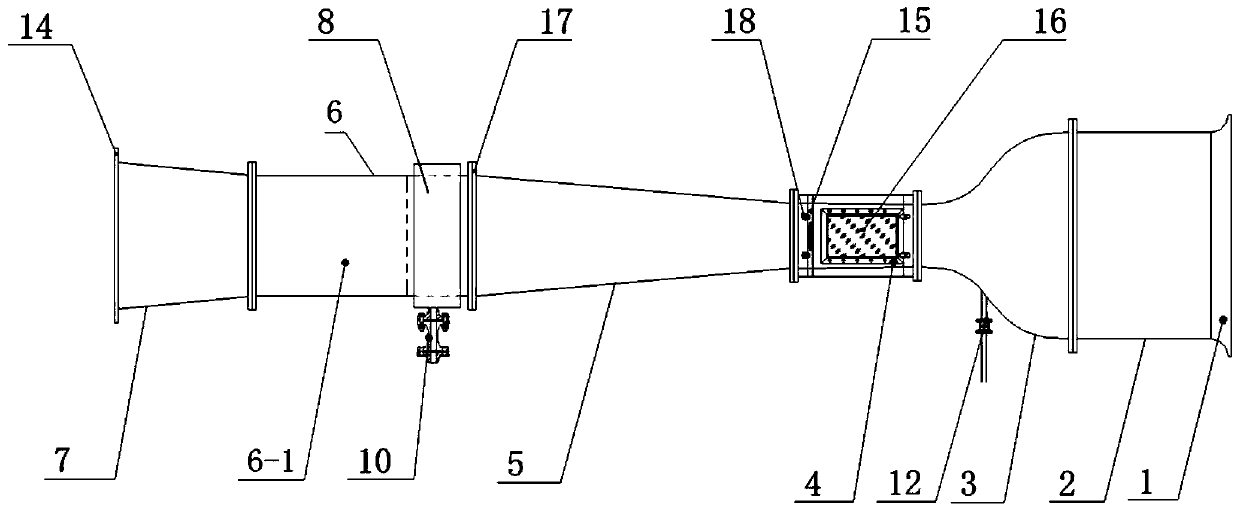

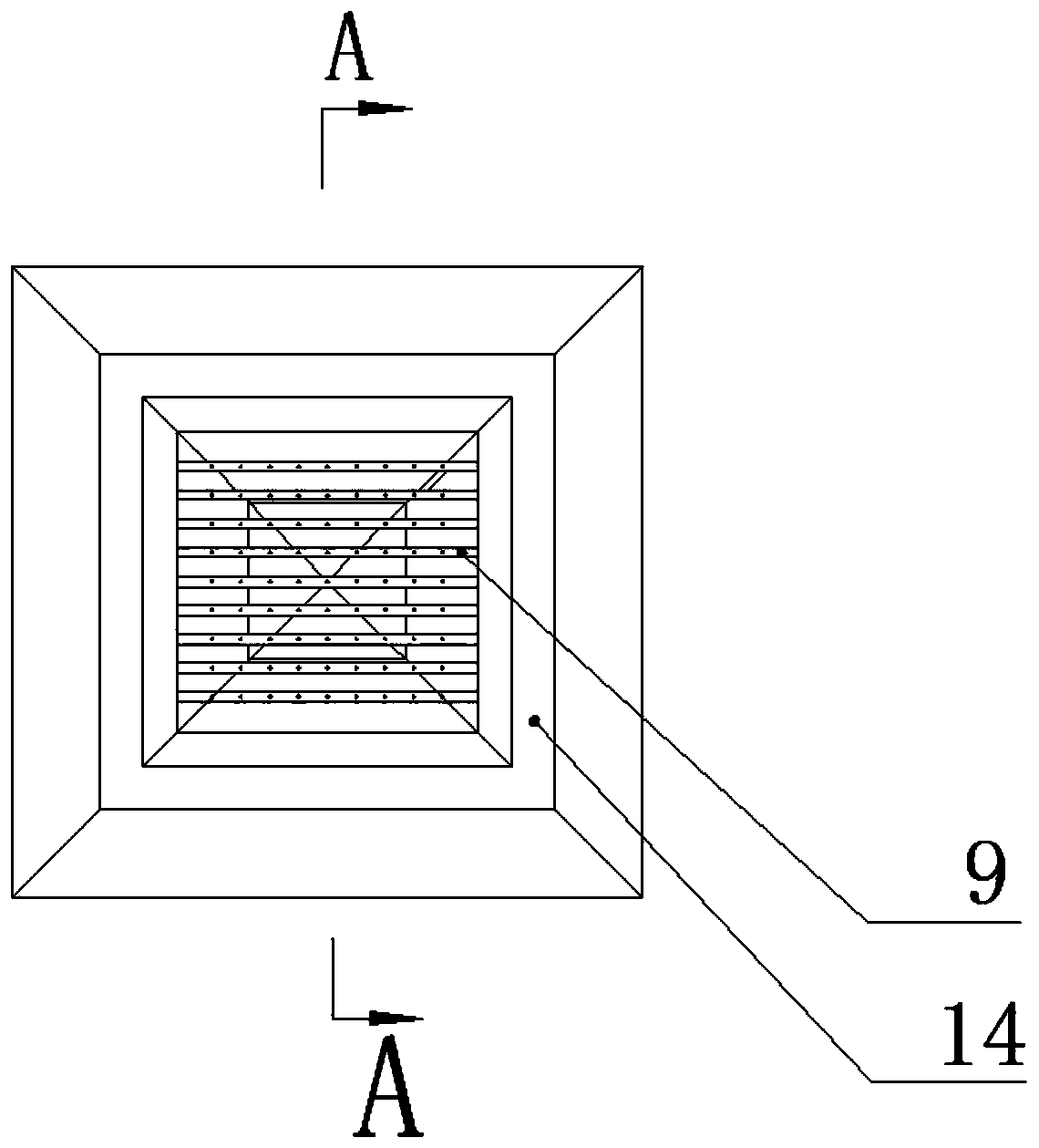

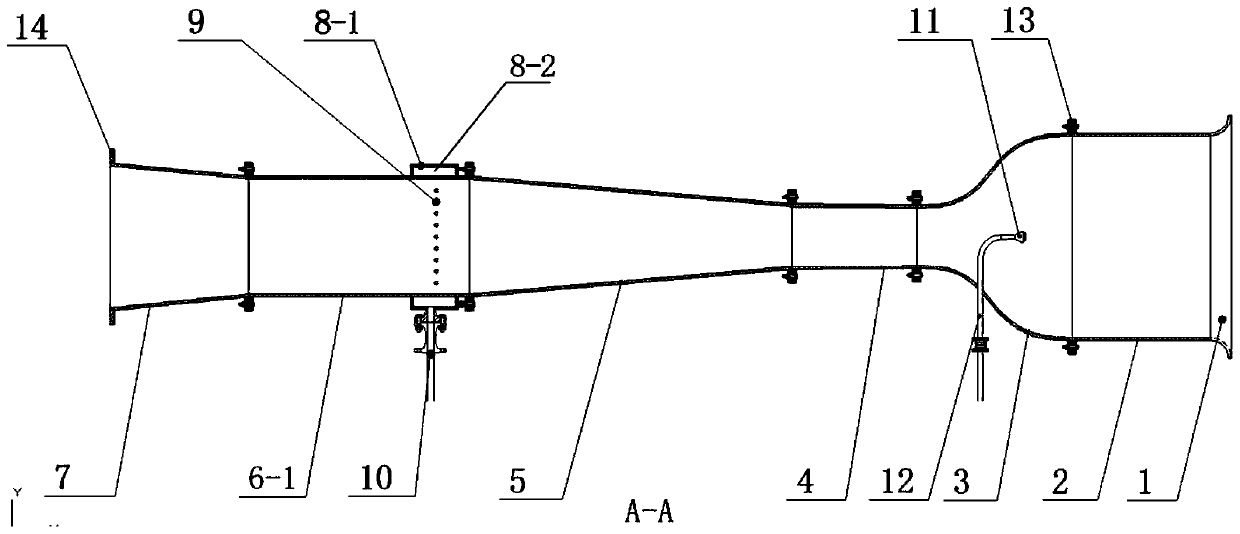

[0017] A Martian wind tunnel with sand and dust simulation. The wind tunnel is placed horizontally in a low-pressure vacuum container and adopts the structure of a straight-line wind tunnel, including a collector 1, a stable section 2, a contraction section 3, a test section 4, The ejector section 6, the exit diffuser section 7 and the ejector 8, the collector 1 is in the shape of a bell mouth, the collector 1 is connected to the entrance of the stabilizing section 2, the section of the stabilizing section 2 is square, and a layer of honeycomb is reserved inside And the connection port of the multi-layer damping net, the honeycomb and the damping net are optional parts, which can be selected and installed according to the needs of the test. The outlet of the stable section 2 and the inlet of the contraction section 3 are connected by flanges, and the outlet of the contraction section 3 is connected to the test section. The inlet of section 4 is connected by flange. This wind tu...

Embodiment 2

[0023] This embodiment adopts the structure of Embodiment 1, adjusts the air supply flow rate entering the ejector chamber 8 through a high-precision regulating valve, changes the injection flow rate of the ejector, and then changes the wind speed in the test section, 9 ejectors 9 nozzles of the device are arranged in parallel at equal intervals, and each nozzle has 9 injection holes, a total of 81 holes.

Embodiment 3

[0025]This embodiment adopts the structure of Embodiment 1. When carrying out the sand and dust simulation test, the method of conveying sand and dust by pressure feeding is adopted, so that the test gas with higher pressure enters the sand and dust conveying pipeline 12 and mixes with the sand and dust for transportation. The Venturi injector is finally ejected from the sand dust nozzle 11 in the contraction section. In order to spread the sand dust in the test section 4 evenly, the outlet structure of the sand dust nozzle 11 adopts a multi-layer staggered form, and adopts the injection direction of the reverse air flow , this method can also keep the nozzle away from the entrance of the test section and improve the flow field quality of the test section. When the sand and dust test simulation is not needed, the sand and dust nozzle and its pipeline can be removed, and the dust concentration meter can be removed at the same time to further improve the flow field quality of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com