Deepwater surface conduit feeding tool function test experimental device and method

A technology for feeding tools and functional testing, which is applied in the field of offshore oil and gas drilling, can solve problems such as ineffective realization of functions, high cost of deepwater drilling, and restriction of drilling efficiency, so as to improve efficiency and reduce the number of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 provides an experimental device for testing the function of a deep-water surface conduit delivery tool, and its structure will be described in detail below.

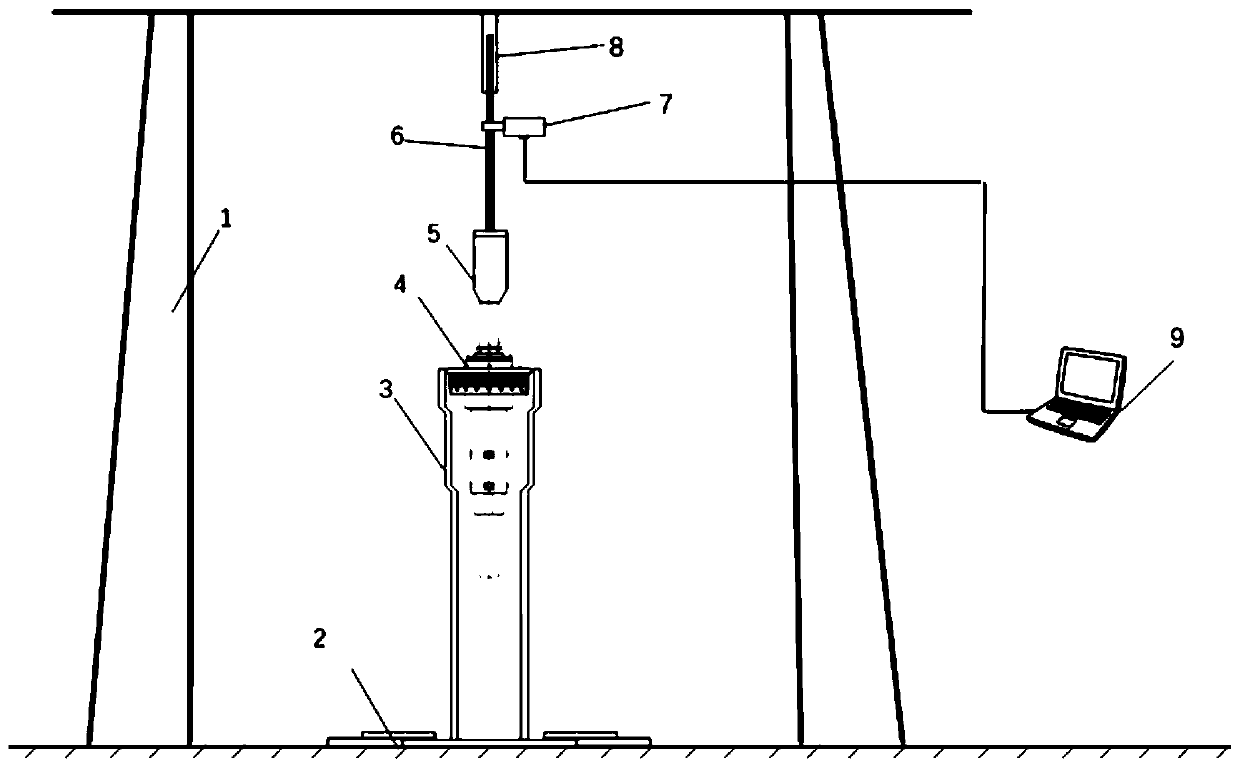

[0041] refer to figure 1 , the deep-water surface conduit feeding tool function test experimental device includes an experiment frame 1, a base 2, a low-pressure wellhead head 3, a deep-water surface conduit feeding tool 4, an adapter 5, a drill pipe 6, a rotating motor 7, a telescopic cylinder 8, a control Device 9.

[0042] The base 2 is arranged at the bottom of the test frame 1, specifically, the base 2 is a reinforced concrete structure base. The low-pressure wellhead head 3 is fixed on the base 2 by fastening bolts.

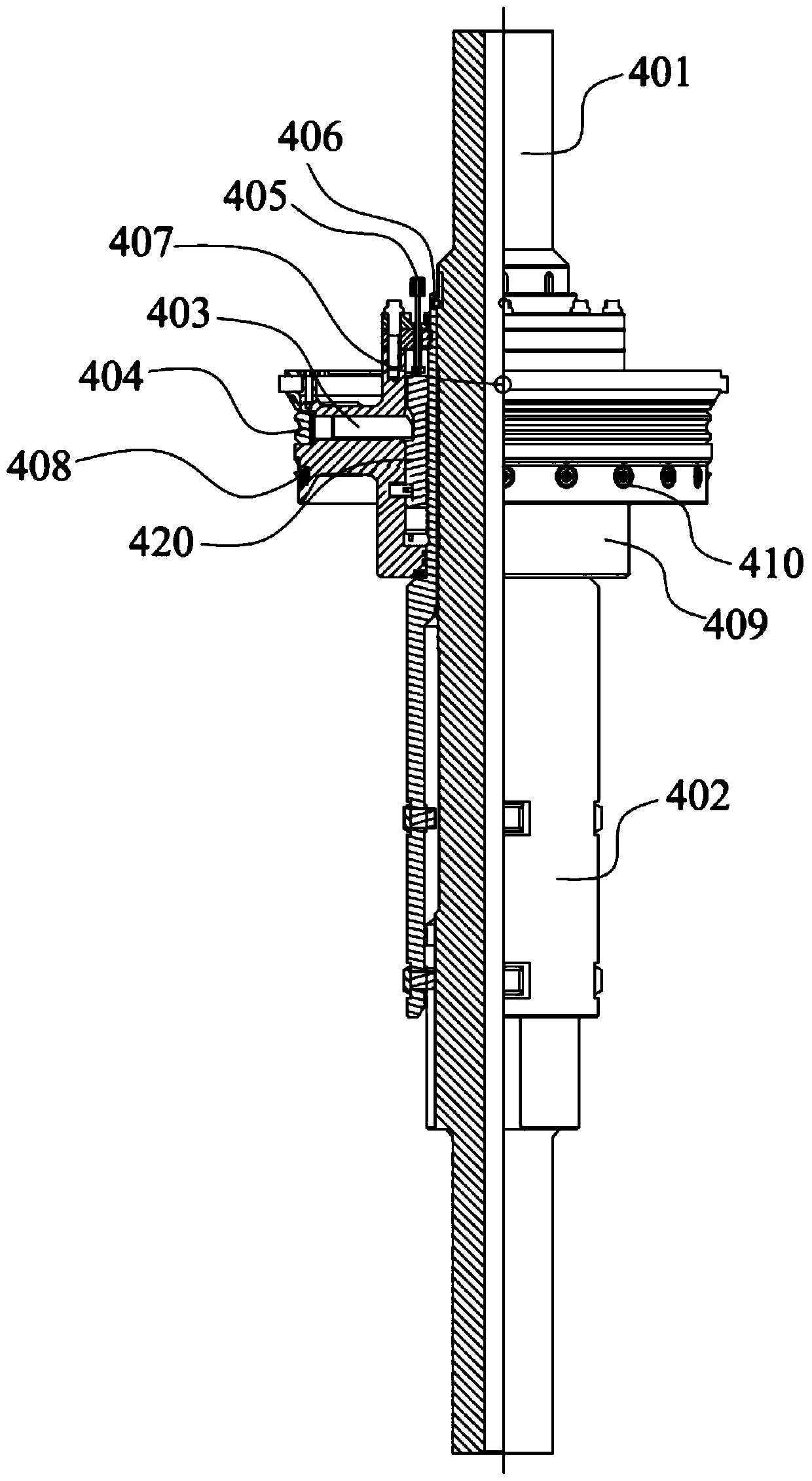

[0043] The upper part of the low-pressure wellhead head 3 is a deep-water low-pressure wellhead head, which is provided with two bosses, and the lower part of the deep-water surface conduit feeding tool 4 is provided with two flanges. The flange on the lower part of the tool 4 i...

Embodiment 2

[0063] Embodiment 2 provides a kind of deep-water surface layer conduit sending tool function test experimental method, adopts the deep-water surface layer conduit sending tool function test experimental device provided in embodiment 1, this functional test experimental method comprises the locking of deep-water surface layer conduit sending tool 4 The locking reliability evaluation method thereof, the unlocking method of the deep-water surface conduit sending tool 4, the release method of the deep-water surface conduit sending tool 4, and the recovery method of the deep-water surface conduit sending tool 4, etc.

[0064] Wherein, the locking method of deep-water surface conduit sending tool 4 comprises the following steps:

[0065] Step S11: Select the power of the rotating motor 7;

[0066] Step S12: Set the rotation output force and the number of rotations of the rotary motor 7, and start the rotary motor 7;

[0067] Step S13: The rotary motor 7 drives the drill pipe 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com