Method for determining contents of gold, platinum and palladium in high-silver high-platinum-palladium chemical slag

A platinum, palladium and chemical technology, applied in the field of non-ferrous metallurgy, can solve the problems of shortening the detection process, platinum and palladium dissolution loss, inability to effectively separate gold, etc., and achieve the effect of shortening the analysis process and shortening the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

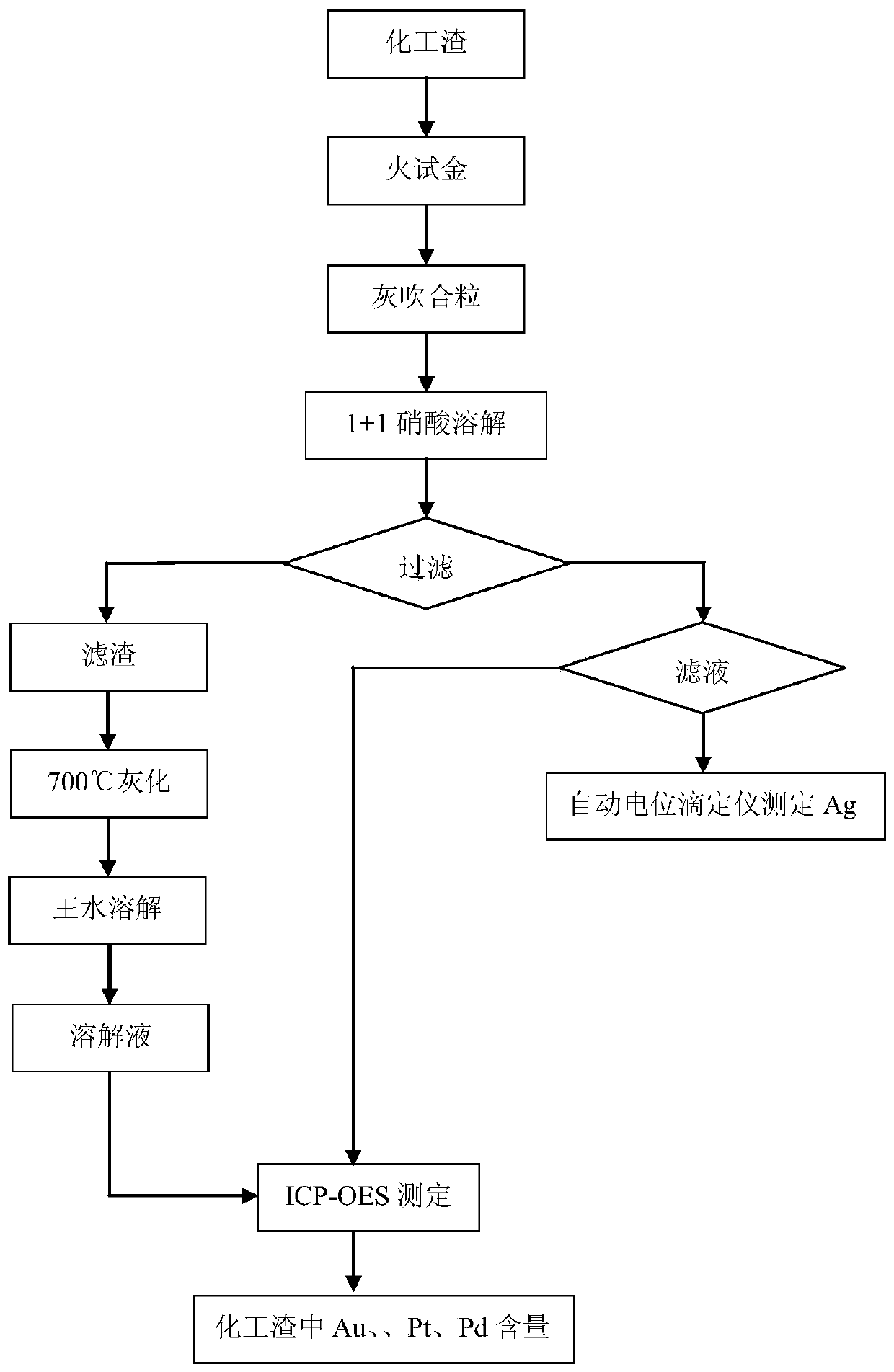

Method used

Image

Examples

Embodiment 1

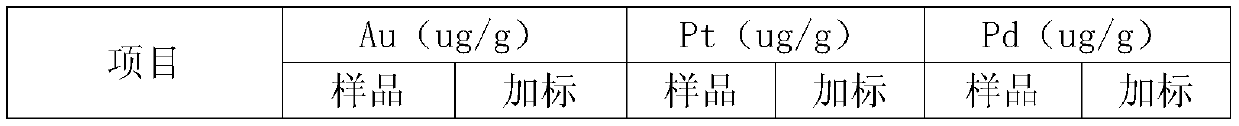

[0029] The standard addition recovery rate of sample 1 is 99.1~101.9%, as shown in Table 1,

[0030]

[0031]

[0032] Table 1

[0033] The relative standard deviation (RSD) of sample 1 is 0.56%~1.54%, as shown in table 2,

[0034] project Au(ug / g) Pt(ug / g) Pd(ug / g) 1 526.1 1001 1999 2 520.5 1036 2000 3 513.2 1031 2002 4 503.4 1043 2008 5 511.2 1048 2009 6 513.1 1018 2019 7 520.3 1040 2025 8 523.2 1045 2027 average value 516.4 1033 2011 Relative standard deviation RSD(%) 1.44 1.54 0.56

[0035] Table 2

Embodiment 2

[0037] The standard addition recovery rate of sample 2 is 96.5%~108.3%, as shown in Table 3,

[0038]

[0039] table 3

[0040] The relative standard deviation (RSD) of sample 2 is 0.48%~2.47%, as shown in table 4,

[0041]

[0042]

[0043] Table 4

Embodiment 3

[0045] The standard addition recovery rate of sample 3 is 100.4~102.5%, as shown in Table 5,

[0046]

[0047] table 5

[0048] The relative standard deviation (RSD) of sample 3 is 0.37%~0.43%, as shown in table 6,

[0049] project Au(ug / g) Pt(ug / g) Pd(ug / g) 1 995.9 1989 2986 2 997.5 1991 2987 3 1003 1993 2989 4 989.9 2002 2995 5 993.2 1997 2996 6 998.7 1995 3006 7 996.5 1989 3012 8 1002 2001 3014 average value 997.1 1995 2998 Relative standard deviation RSD(%) 0.43 0.25 0.37

[0050] Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com