Photosensitive composition and application thereof

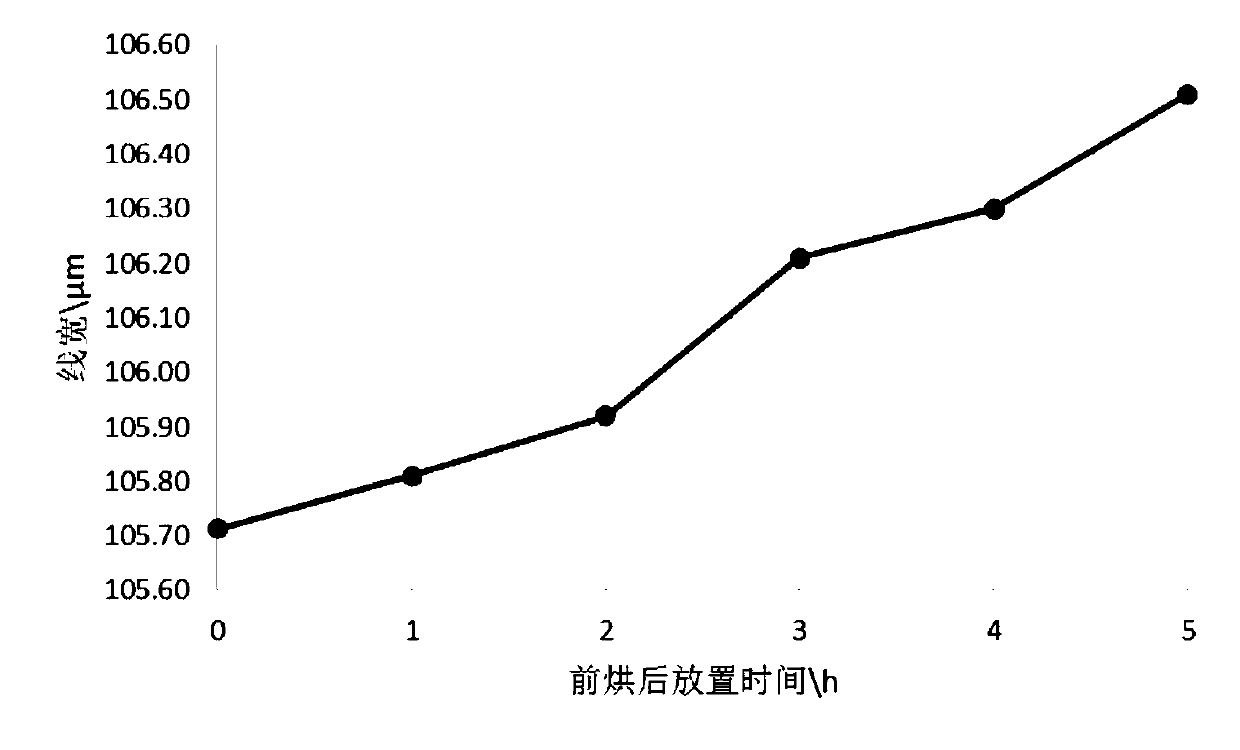

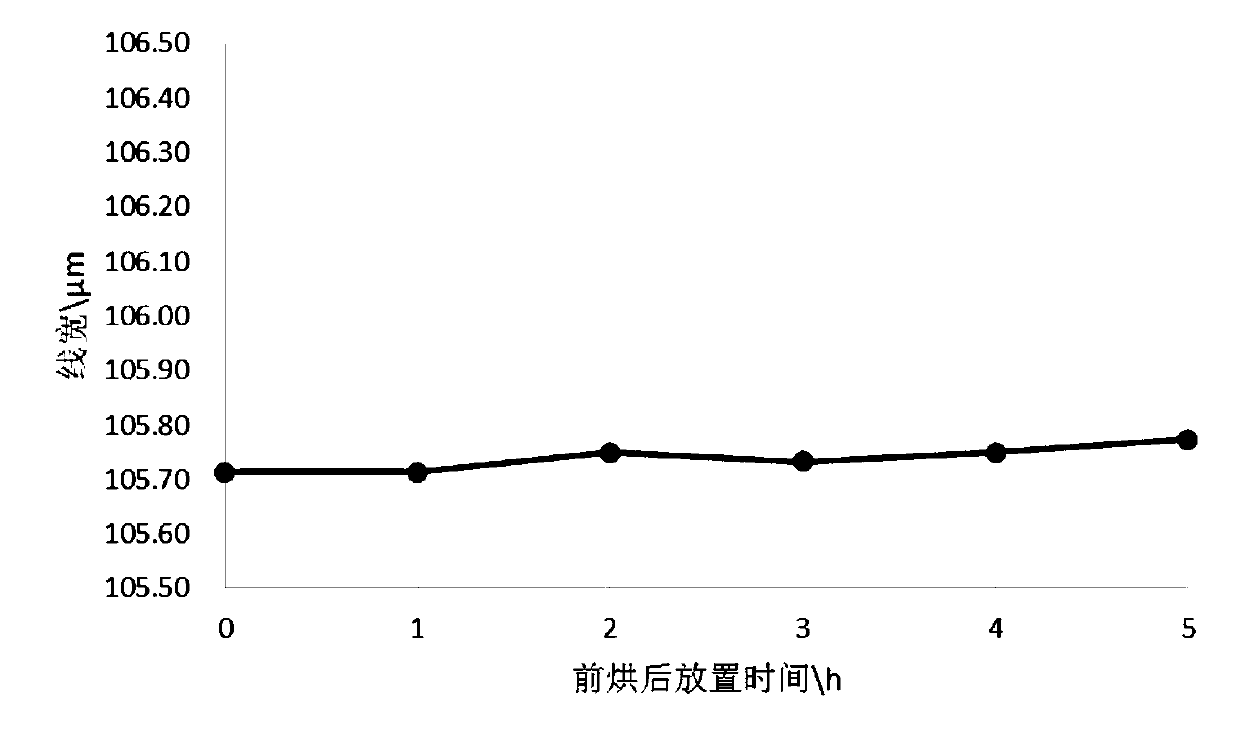

A composition and aromatic compound technology, applied in optics, optical components, optomechanical equipment, etc., can solve the problems of lower product yield, increased line width, and increased difficulty of development, etc., to achieve weakened dark reaction and high tolerance , the effect of stable line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

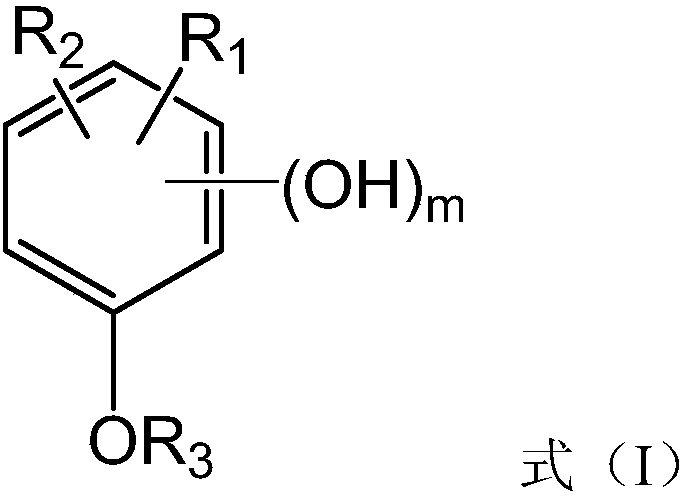

Method used

Image

Examples

Embodiment 1

[0061] A kind of preparation of photosensitive composition:

[0062] Get 40 parts by weight of alkali-soluble resin Sarbox SB400 (purchased from Sartomer), 65 parts by weight of dipentaerythritol hexaacrylate (purchased from Sartomer), 100 parts by weight of G36+Y150 pigment (wherein G36 is 50 parts by weight, Y150 is 50 parts by weight) (purchased from DIC company), 6 parts by weight photoinitiator OXE-01 (Basf company), 1.5 parts by weight BYK-333 leveling agent (purchased from BYK company), 260 parts by weight solvent propylene glycol methyl ether Acetate (purchased from Dow Company), 1.5 parts by weight of silane coupling agent OFS-6030 (purchased from Dow-Corning Company), 0.6 parts by weight of aromatic compound 1 A photosensitive composition is obtained.

Embodiment 2

[0064] The difference from Example 1 is that the aromatic compound 1 Replaced by Aromatic Compound 2

Embodiment 3

[0066] The difference from Example 1 is that the aromatic compound 1 Replaced by Aromatic Compound 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com