Die for processing special-shaped conductor

A technology of circular conductors and conductors, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, electrical components, etc., can solve the problems of reducing cable diameter and cross section, cable diameter cannot be reached, cannot be reached, etc. , to achieve the effect of reducing consumables, reducing diameter and reducing production consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

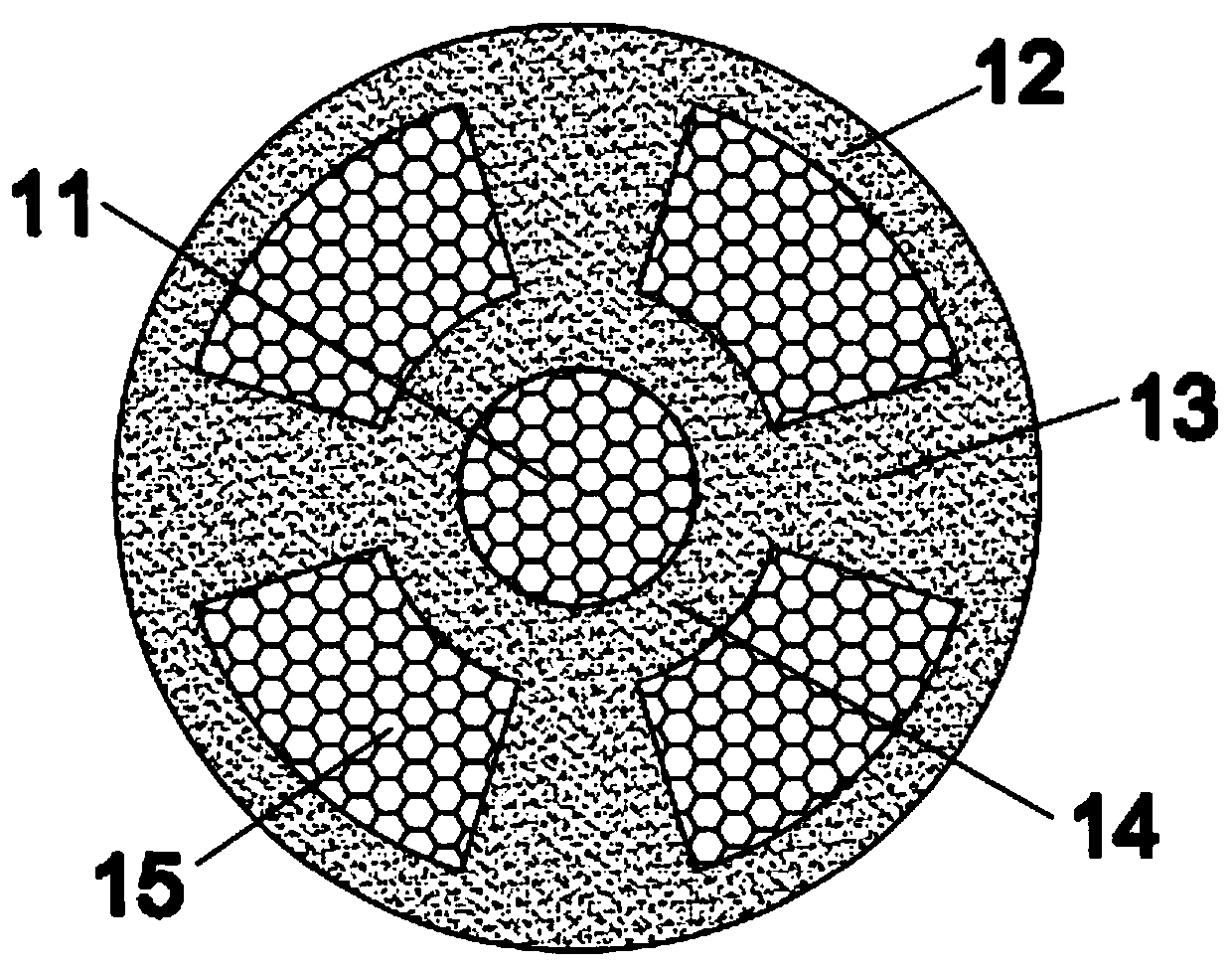

[0025] Such as figure 1 Among them, it is a cross-sectional schematic diagram of a special-shaped conductor produced by a mold for processing a special-shaped conductor adopting the technical solution of the present invention, wherein the mark 11 is a circular conductor layer, the mark 14 is a circular conductor filling layer, and the mark 13 is a special-shaped conductor filling mold , mark 15 is the special-shaped conductor layer, and mark 12 is the wrapping layer.

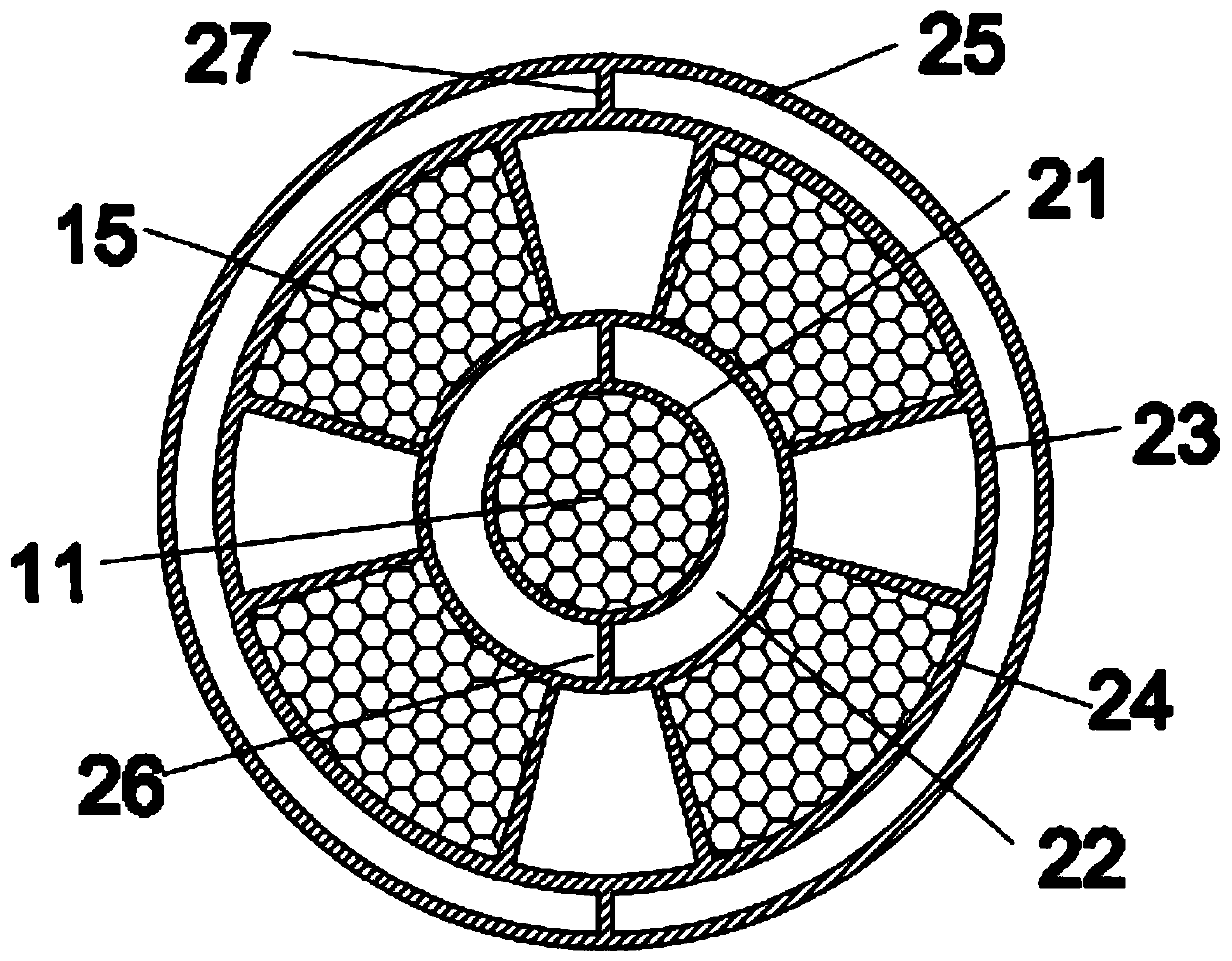

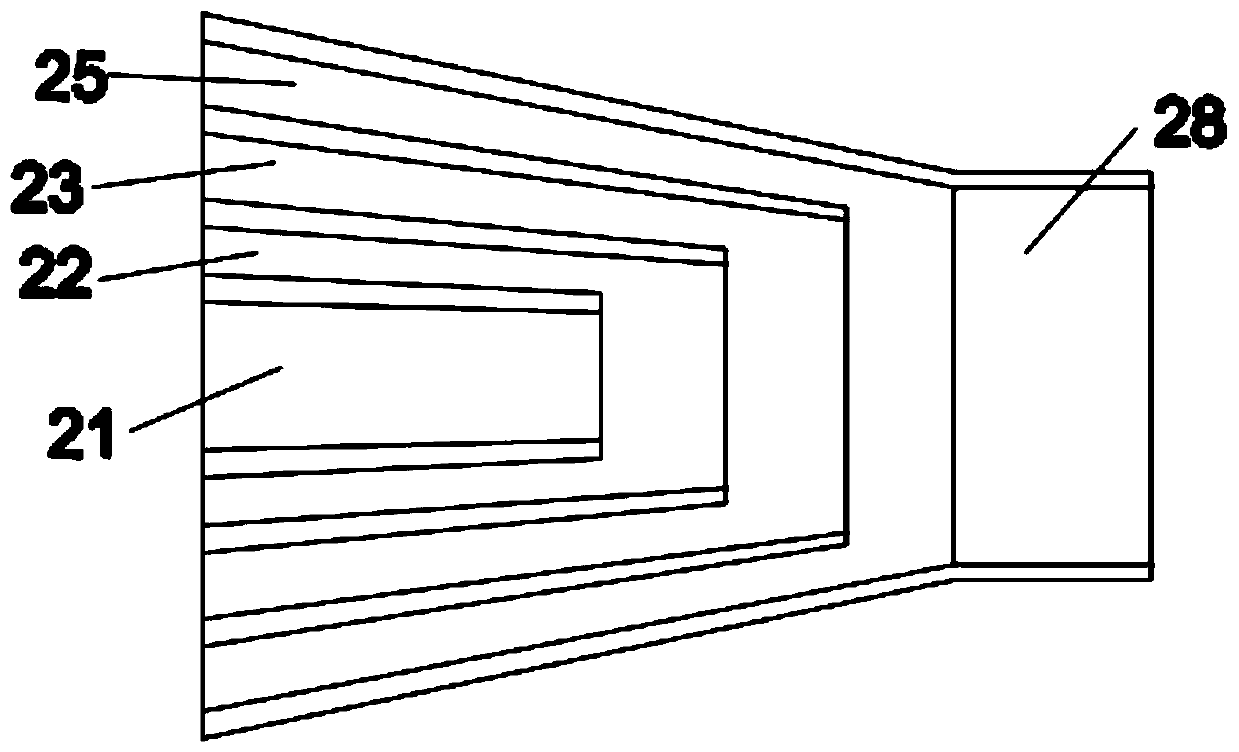

[0026] Such as figure 2 and image 3 As shown, when producing special-shaped conductors, this mold is installed on the nozzle end of the extruder, and the base rubber of the extruder is used to fill the outside of the conductor to realize the isolation and wrapping of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com