Stator core liquid cooling system

A stator core, liquid cooling technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of cooling system failure, high risk of short circuit, scale and impurities that are easy to block pipelines, etc., to achieve pipeline pressure. Low, improve the adaptation range, the effect of stable and reliable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

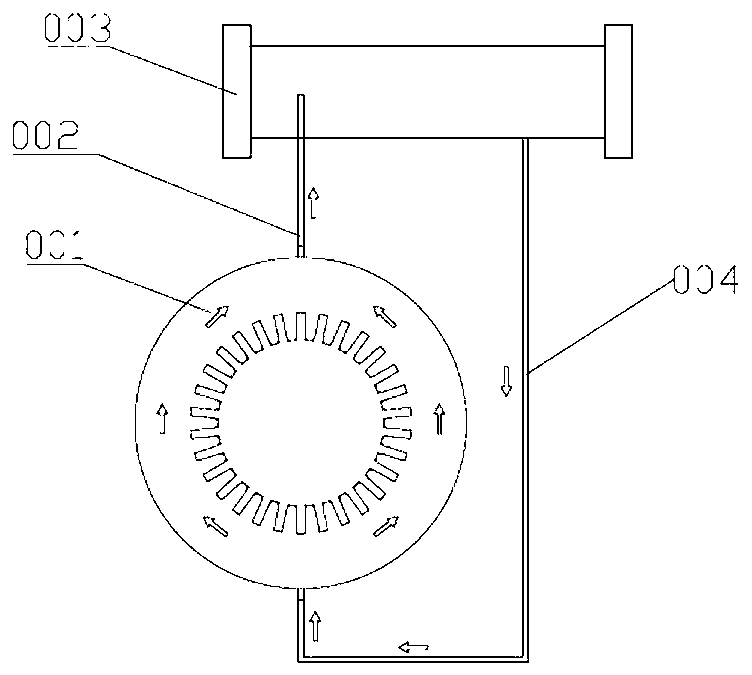

[0052] Embodiment 1 Stator core radial self-circulating liquid cooling system of horizontal motor

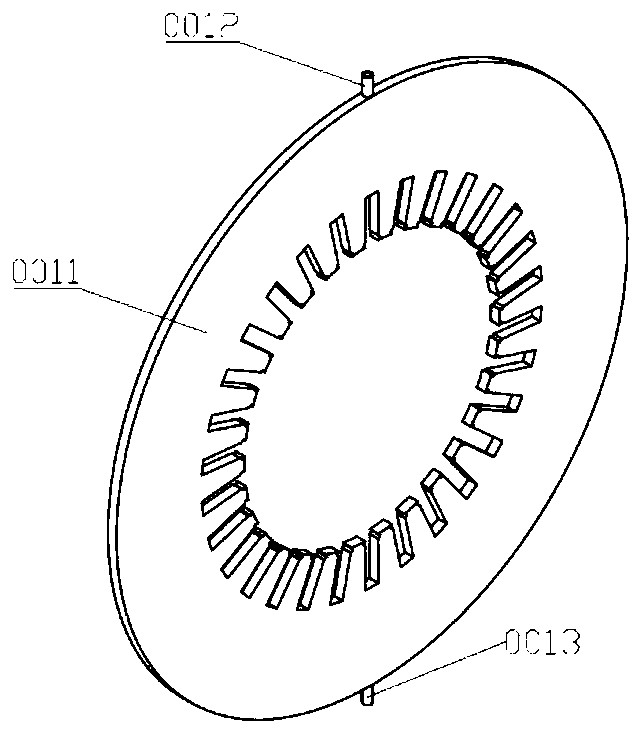

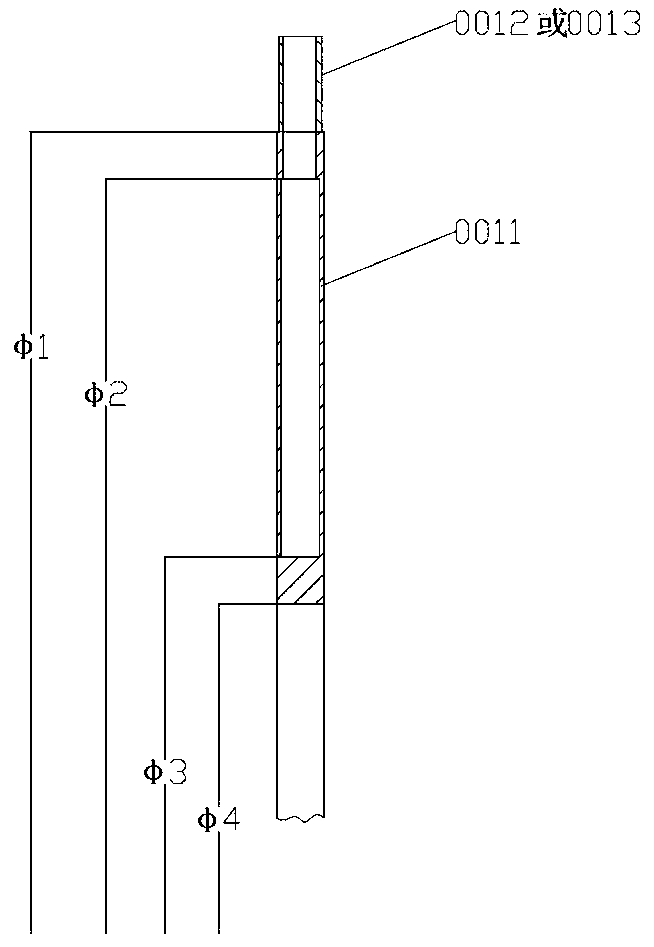

[0053]For horizontal motors, self-circulating liquid cooling can be realized by adopting stator iron core radial liquid cooling system. The flow of cooling medium does not need to be driven by circulating pumps. The cooling system is simple in structure and consumes almost no energy. The circulation mode of the radial self-circulating liquid cooling system of the stator core of the horizontal motor is as follows: figure 1 As shown, the arrows in the figure indicate the circulation direction of the cooling medium, among which, 001-cold plate, 002-outlet channel, 003-condenser, 004-liquid return channel, one end of the cold plate 001 or the core cooling pipe is connected to the outlet channel 002 , the other end is connected to the liquid return channel 004, and a condenser 003 is arranged between the gas outlet channel 002 and the liquid return channel 004. When the motor is run...

Embodiment 2

[0061] Embodiment 2 Stator core axial self-circulation liquid cooling system of vertical motor

[0062] For the vertical motor, the stator core axial liquid cooling system can realize self-circulating liquid cooling. The flow of the cooling medium does not need to be driven by a circulating pump. The cooling system has a simple structure and consumes almost no energy. The circulation mode of the axial self-circulating liquid cooling system of the stator core of the vertical motor is as follows: Figure 11 As shown, the arrows in the figure indicate the circulation direction of the cooling medium. Among them, 005-single-layer tubular core cooling pipe. The single-layer tubular core cooling tube 005 is a seamless metal tube arranged along the circumference in the stator core. When the single-layer tubular iron core cooling pipe 005 is in different radial positions, it can be coated with insulating material according to design requirements. When the motor is running, the heat ...

Embodiment 3

[0064] Embodiment 3 pump-driven stator core liquid cooling system

[0065] When the motor is installed obliquely at a small angle, within a certain angle, whether it is a radial liquid cooling system or an axial liquid cooling system, the iron core can be cooled by self-circulation. However, when the inclination angle of the motor is too large, when the radial liquid cooling system of the stator core is applied to a vertical motor, and when the axial liquid cooling system of the stator core is applied to a horizontal motor, it is necessary for the circulation pump to drive the cooling medium to overcome the flow resistance. cycle. Including the following two situations:

[0066] (1) Pump driven stator core radial liquid cooling system

[0067] When the motor is installed vertically or close to vertically inclined and the radial liquid cooling system of the stator core is used, the circulation power of the liquid cooling system is relatively small, and a circulating pump is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com