Linolenic acid compound drink and preparation method thereof

A technology of linolenic acid and beverages, which is applied in dairy products, food ingredients, milk preparations, etc., and can solve problems such as inaccurate product standards, many equipments, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

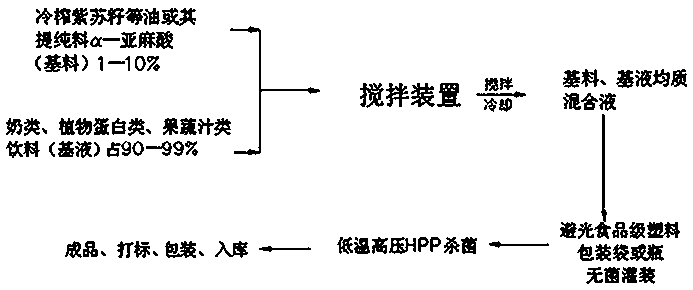

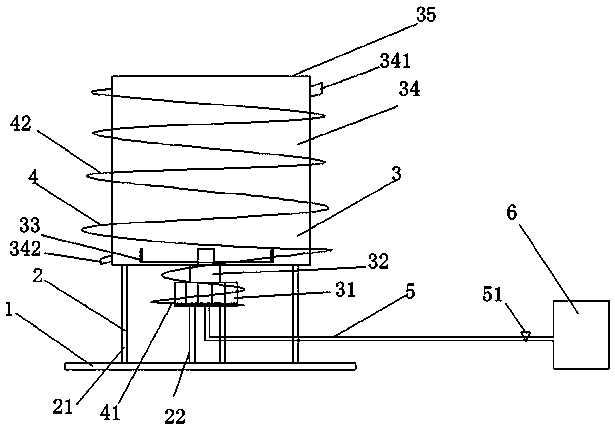

Method used

Image

Examples

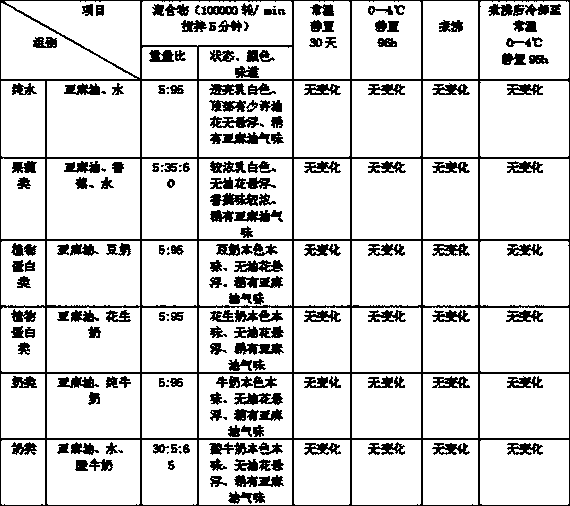

Embodiment 1

[0038] Embodiment 1, 5% linseed oil, 35% bananas, and 60% pure water are added to the mixing tank 34, and the stirring motor 31 and the refrigerator 6 are started at the same time, that is, the materials in the mixing tank 31 are stirred at a high speed. Cooling is carried out, the rotating speed of the stirring motor 31 is 100000 r / min, the stirring time is kept at 5min, the linseed oil is completely emulsified, and a uniformly mixed liquid is obtained. The mixture is milky white, without suspension and stratification, with a slight smell of linseed oil and a strong banana smell.

[0039] Further, the banana-flavored mixed solution was left standing at room temperature for 30 days, and the mixed solution remained unchanged; the banana-flavored mixed solution was left to stand at 0-4°C for 96 hours, and the mixed solution remained unchanged; the banana-flavored mixed solution was boiled, There was no change in the mixture; when the banana-flavored mixture was boiled and cooled...

Embodiment 2

[0041] Embodiment 2, 5% linseed oil and 95% soybean milk are added in the mixing tank 34, and the stirring motor 31 and the refrigerator 6 are started at the same time, that is, the material in the mixing tank 31 is stirred at a high speed while cooling, and the stirring motor 31 The rotation speed of the machine is 100000r / min, the stirring time is kept at 5min, the linseed oil is completely emulsified, and a uniformly mixed mixture is obtained. The surface of the mixture is free of oil suspension and stratification, the mixture has a slight smell of linseed oil, and the overall taste of soy milk is present.

[0042] Further, the mixed solution was left standing at room temperature for 30 days, and the mixed solution did not change; the mixed solution was placed at 0-4°C for 96 hours, and the mixed solution remained unchanged; the mixed solution was boiled, and the mixed solution remained unchanged; the mixed solution was boiled After cooling to normal temperature, the mixtur...

Embodiment 3

[0044] Embodiment 3, 5% linseed oil and 95% peanut milk are added in the mixing tank 34, and the stirring motor 31 and the refrigerator 6 are started at the same time, that is, the material in the mixing tank 31 is stirred at a high speed while cooling, and the stirring motor The rotation speed of 31 is 100000r / min, and the stirring time is kept at 5min. At this time, the linseed oil is completely emulsified, and a uniformly mixed mixture is obtained. The surface of the mixed solution has no oil suspension and layering, has a slight smell of linseed oil, and presents the original taste of peanut milk as a whole.

[0045] Further, the peanut milk-flavored mixed solution was left standing at room temperature for 30 days, and the mixed solution remained unchanged; the mixed solution was left at 0-4°C for 96 hours, and the mixed solution remained unchanged; the mixed solution was boiled, and the mixed solution remained unchanged; Boil the mixed solution and cool it to normal tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com