A bopp film production extruder uniform thickness extruder

A technology with uniform thickness and extruder, applied in the field of BOPP film production, can solve the problems of incomplete and uneven plasticization of materials, affecting product quality, etc., and achieve the effect of increasing quality, uniform plasticization, and saving maintenance time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

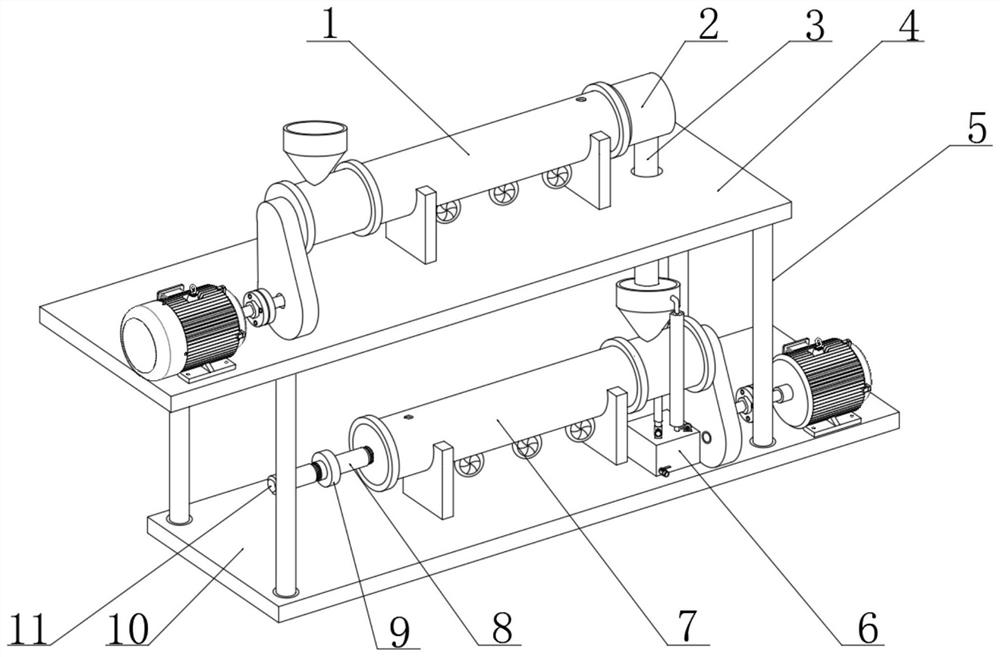

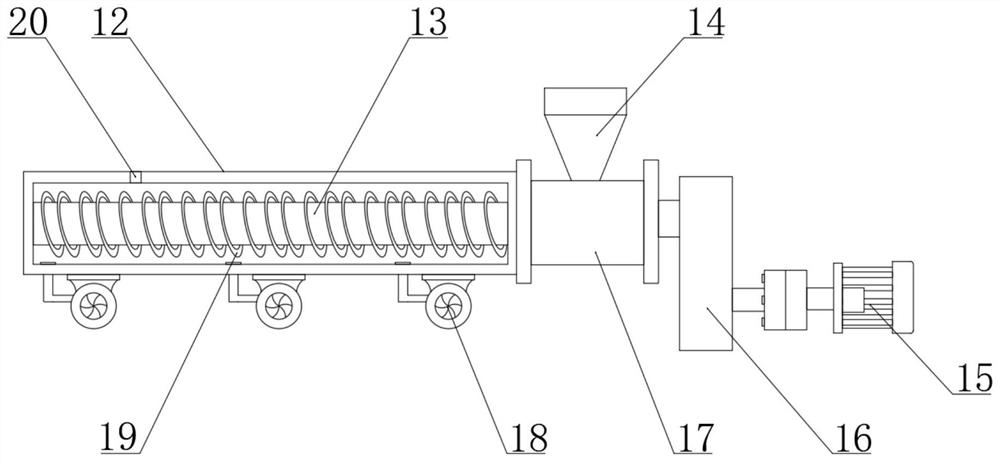

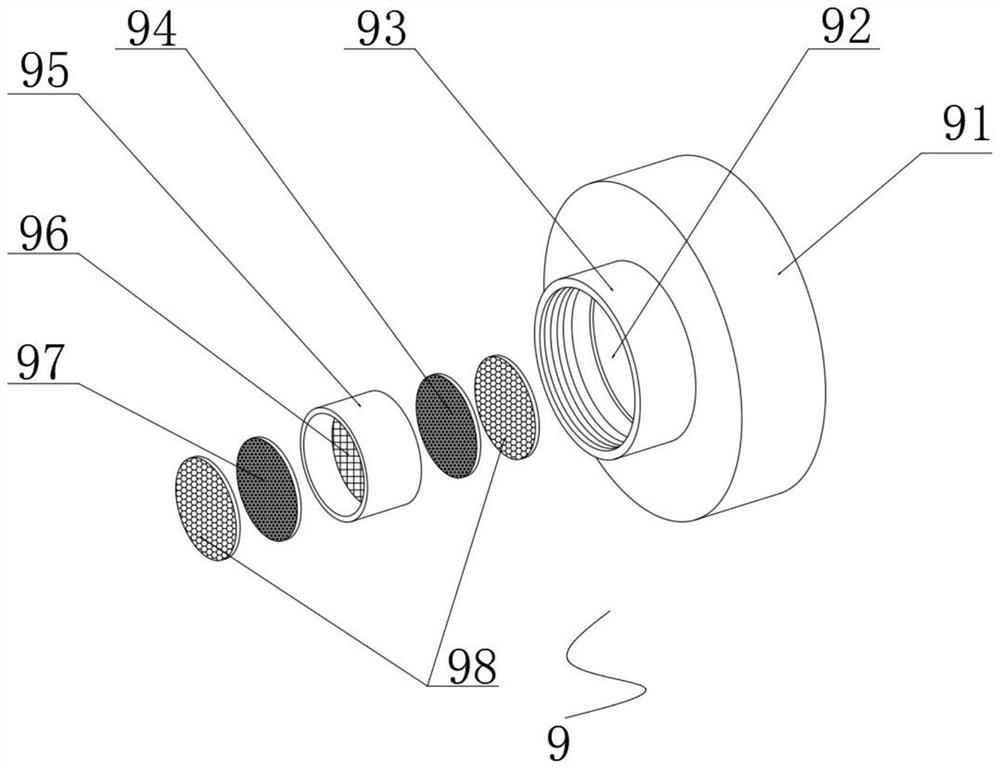

[0021] see Figure 1~5 , in the embodiment of the present invention, a BOPP film production extrusion extruder with uniform thickness includes a base plate 10, an upper support plate 4 is arranged above the base plate 10, and four wires in the form of The guide posts 5 distributed in a rectangle are supported and fixed, and the upper surface of the bottom plate 10 is provided with a second extrusion device 7, the second extrusion device 7 includes an outer tube 12, and a melt tube 13 is provided through the inside of the outer tube 12, and the outer tube One end of 12 is communicated with a feed pipe 17, the surface of the melt pipe 13 is wound with a heating pipe 19, and the inside of the melt pipe 13 is provided with a screw extending to the outside of the feed pipe 17, and the top of the feed pipe 17 is provided with Feed hopper 14, and one end of feed pipe 17 is provided with reduction gear box 16, and one side of reduction gear box 16 is connected with the drive shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com