A gravure printing process and equipment for paper packaging boxes

A technology of printing equipment and box gravure, which is applied in the direction of gravure rotary printing machine, printing, printing machine, etc. It can solve the problems of affecting image simulation, image transition is stiff, and there is no three-dimensional effect, so as to achieve convenient cleaning and typesetting, easy operation, good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A paper packaging box gravure printing process, comprising the following steps:

[0056] S1: Decompose the pattern to be printed according to the color level, and engrave the decomposed pattern on the printing roller with laser mirror image respectively. When performing laser mirror image engraving, determine the depth of the engraved pattern on the printing roller according to the ink thickness of the printed pattern , to complete the engraving of the printing roller; when decomposing the pattern, it can be decomposed according to the level or color of the pattern; when decomposing according to the color, it can be decomposed according to the similarity of its color, and the decomposed layers are based on 3-6 layers. The decomposed image of each layer is subjected to a stereotyped design, and the designed stereotyped pattern is respectively engraved on the printing roller that needs to be printed by laser. The depth of the engraved pattern on the printing roller is 15u-...

Embodiment 2

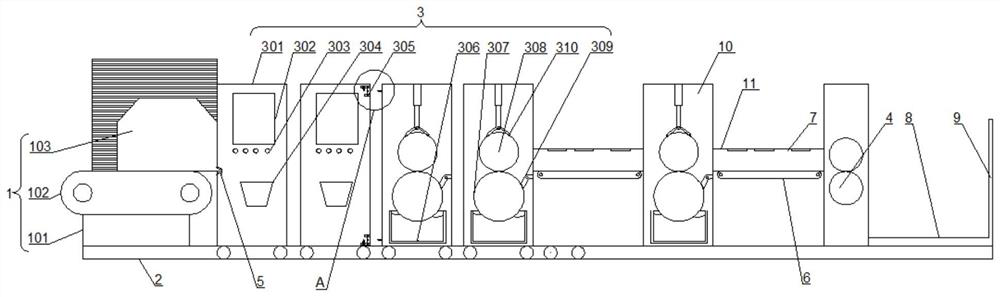

[0070] Such as figure 1 The gravure printing equipment for a paper packaging box shown includes:

[0071] The paper feeding assembly 1 sends the paper to be printed and stacked one by one into the printing assembly 3; the paper feeding assembly 1 includes a base 101, and the top of the base 101 is provided with a second conveyor belt 102, and the two conveyor belts 102 The side is provided with a baffle 103, and the paper placed on the base 101 is transported to the baffle 103 by the conveyor belt 2, and the paper is sent into the printing assembly 3 one by one by the baffle 103; There is a paper inlet 5 to ensure that the paper feeding assembly can feed paper into the printing assembly 3 through the paper inlet 5;

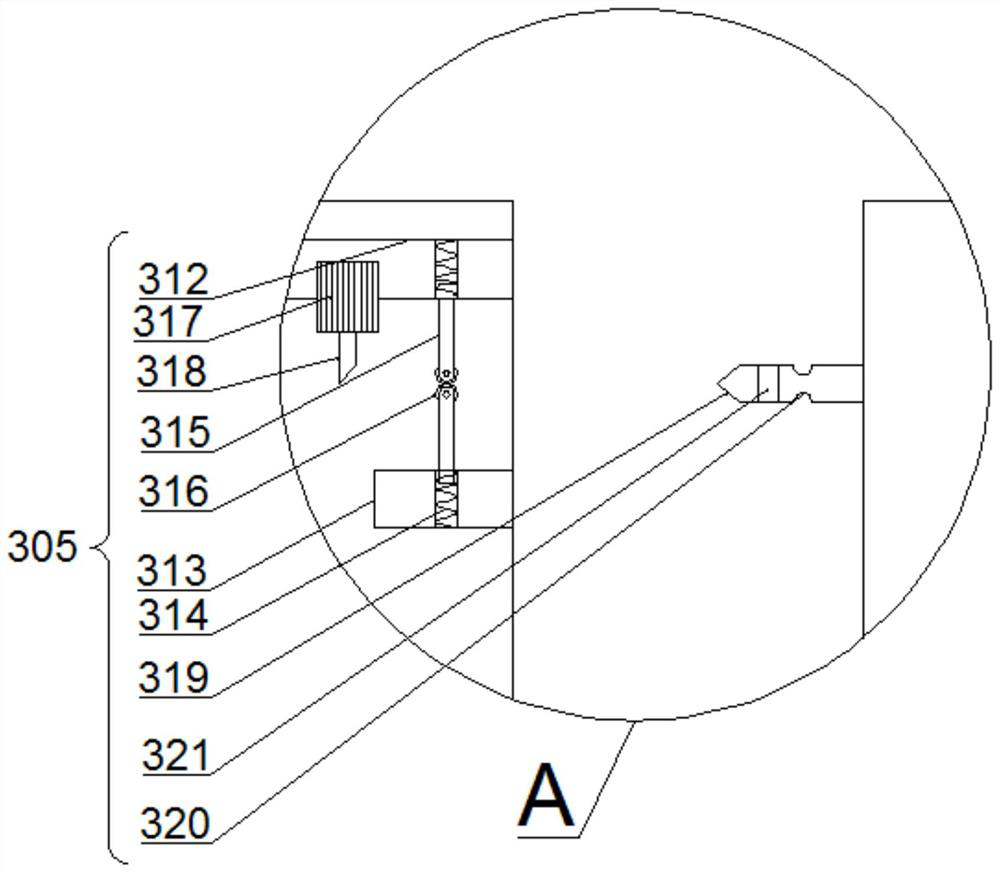

[0072] Several printing assemblies 3, the printing assemblies 3 are sequentially connected through the clamping mechanism 305 according to the printing order of the printing patterns, and the decomposed patterns of the paper entering the printing assemblies 3 are...

Embodiment 3

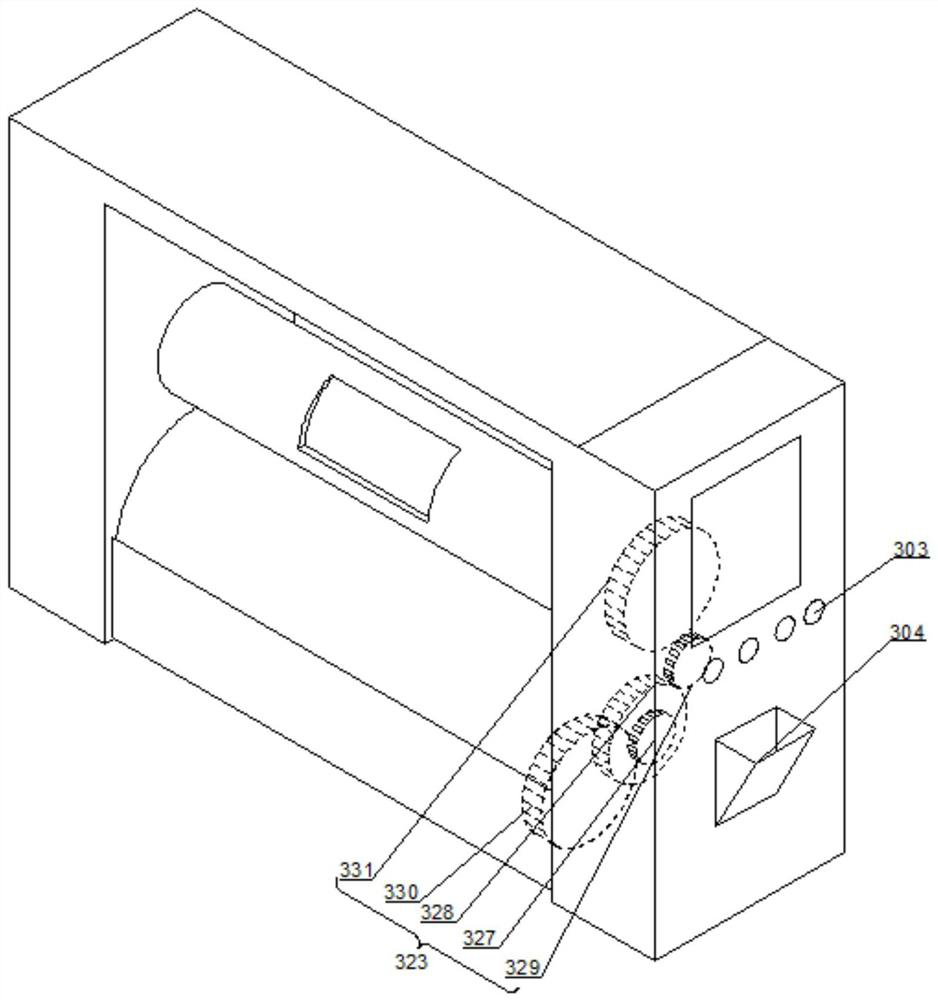

[0079] On the basis of embodiment 2, some of the printing components 3 and the oil layer printing components 10 are the same ink printing components;

[0080] This ink printing assembly comprises frame 301, and the bottom in this frame 301 is provided with ink tank 306, and this ink tank 306 communicates with the ink adding bucket 304 that frame 301 side is provided with; There is an ink roller 307, and the top of the ink roller 307 is provided with a platen roller 308 that is located on the same vertical plane with the central axis of the ink roller 307 and whose central axes are parallel to each other. The ink roller 307 and the platen roller 308 are rotating When rotating to the other side, the lower peripheral surface of the ink roller 307 is in contact with the ink in the ink tank 306; the prepared ink is added to the ink tank through the ink adding bucket, and the ink roller 307 is positioned at the front of the ink tank Above and in contact with the ink in the ink tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com