Sewage ecological treatment system

A technology of ecological treatment and ecological treatment pool, applied in the direction of biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor purification effect, increased treatment cost, and impact on ecology Degradation and absorption of vegetation layer, to achieve the effect of enhancing oil and impurity removal ability, promoting discharge efficiency, and ensuring anti-blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

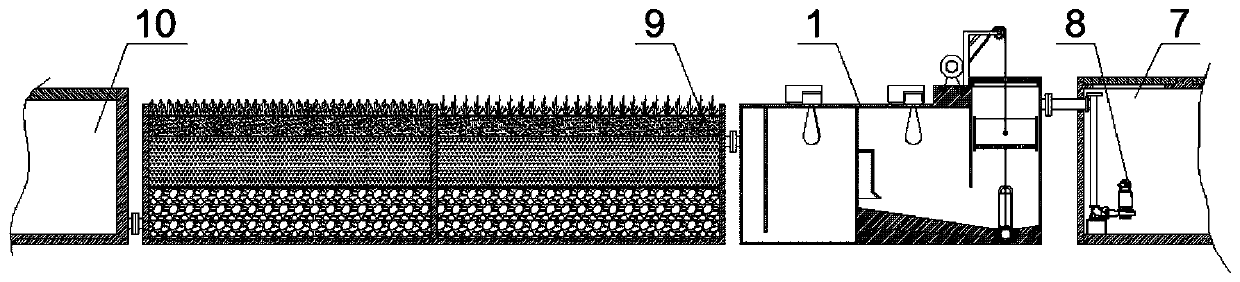

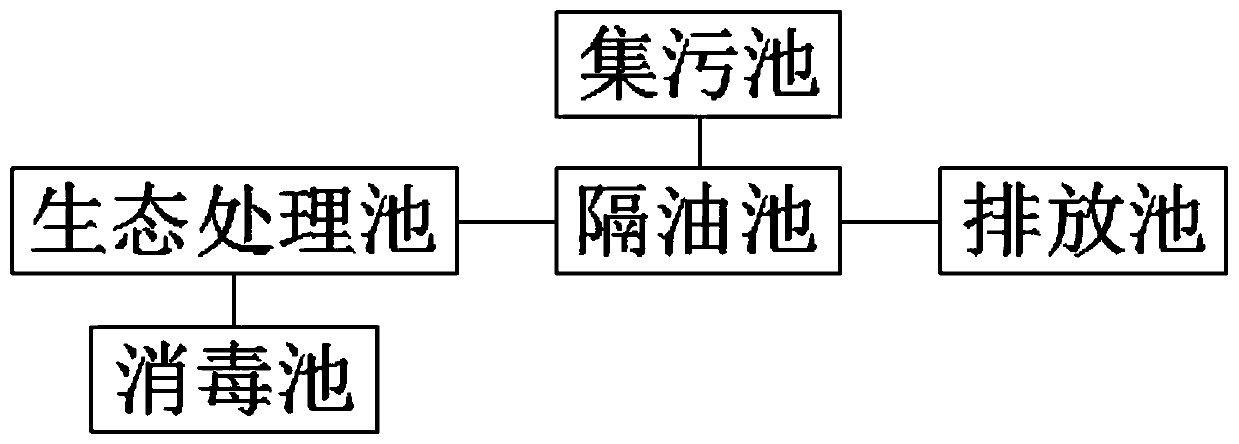

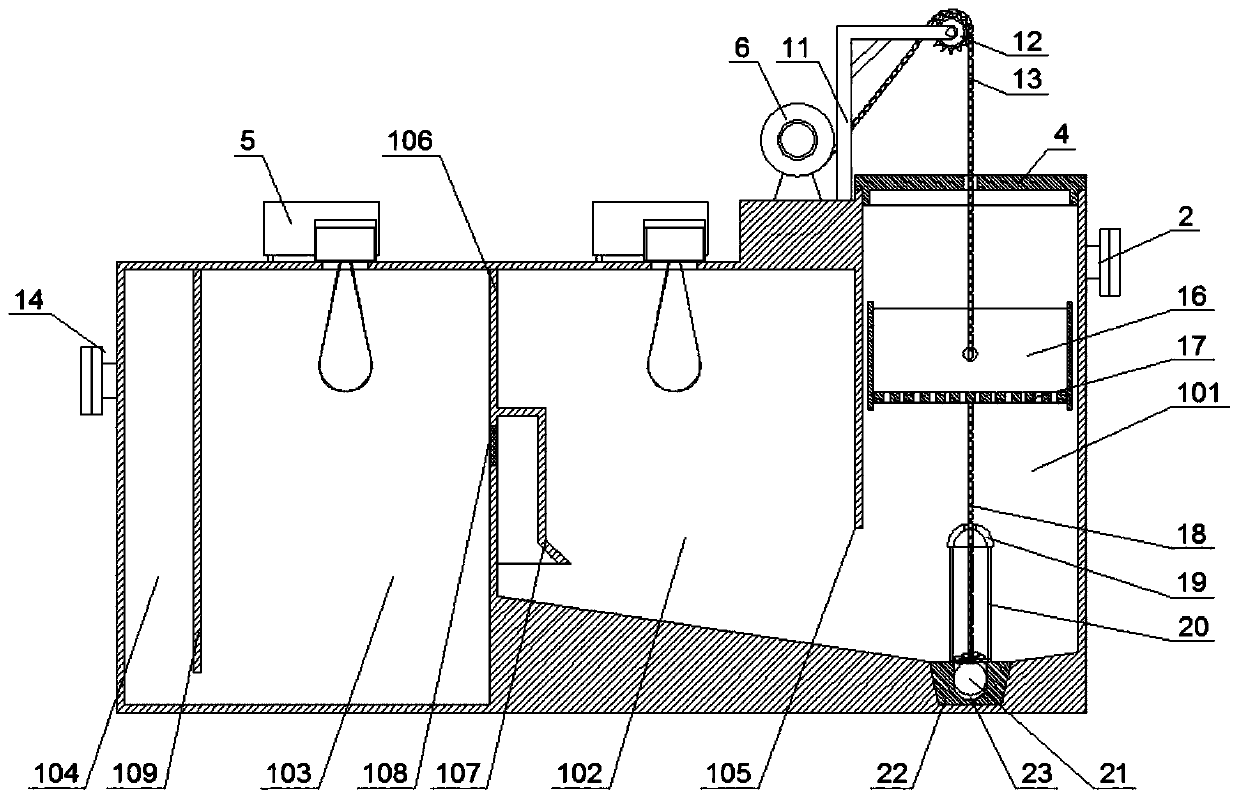

[0021] Such as Figure 1 ~ Figure 4 As shown, the sewage ecological treatment system provided in this embodiment includes a discharge pond 7, a grease trap 1, an ecological treatment pond 9 and a disinfection pond 10 connected by pipelines in sequence, and the water inlet end of the discharge pond 7 is used to receive industrial waste to be purified. For waste water, a cutting-type submersible sewage pump 8 is installed at the water outlet of the discharge pool 7. The cutting-type submersible sewage pump 8 adopts existing mature products, which can cut the large garbage in the industrial wastewater into small garbage and then discharge it to prevent damage to the system. The top of the grease trap 1 is capped and an inspection port is processed on the cap. Capping refers to changing the form of the upper opening of the grease trap 1 into a sealed form to improve a certain degree of safety and prevent a large amount of peculiar smell. dissipated in the air.

[0022] The inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com