A direct silicon controlled process for sae1006crqz steel

A technology of process and steel grade, applied in the field of direct supply silicon controlled process, can solve problems such as the deterioration of the wire feeding process, and achieve the effect of guaranteeing the pourability of continuous casting, ensuring the pourability of molten steel, and reducing flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

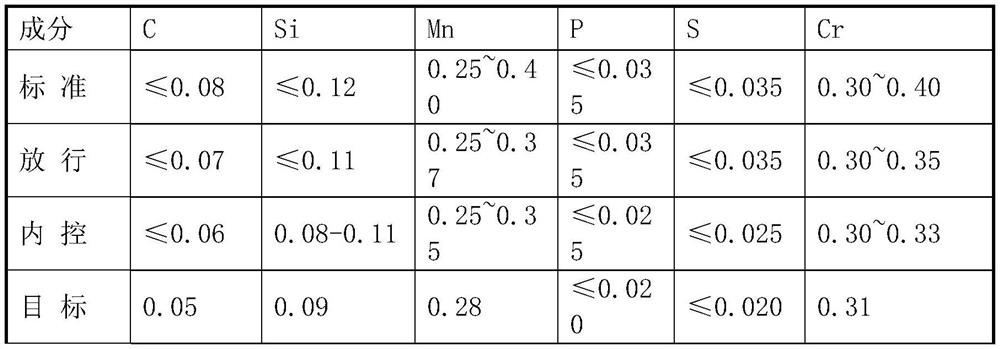

[0023] The present invention is used for the direct supply silicon control technology of SAE1006CrQZ steel type, specifically comprises the following steps:

[0024] (1) According to the production plan, three furnaces were continuously tested in the early stage of pouring, and ferrosilicon powder was used in the test instead of silicon-calcium wire or calcium-iron wire;

[0025] (2) The converter increases the rate of one-time downturning, strives for one-time downturning, and at the same time strengthens the slag blocking operation in the tapping process to reduce the pressure for the subsequent deoxidation treatment of molten steel;

[0026] (3) Operating requirements for argon blowing and deoxygenation in the argon station:

[0027] After the molten steel arrives at the station, turn on the argon gas and blow it for 1 minute to ensure that the slag on the liquid surface of the ladle is completely blown away. Conditions to adjust the addition of ferrosilicon powder.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com