Photoresist bleaching and baking method and device

A baking device and photoresist technology, applied in the directions of light guides, optics, optical components, etc., can solve problems such as affecting production efficiency and long production distance, and achieve the effects of improving production efficiency, improving adaptability, and reducing equipment procurement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

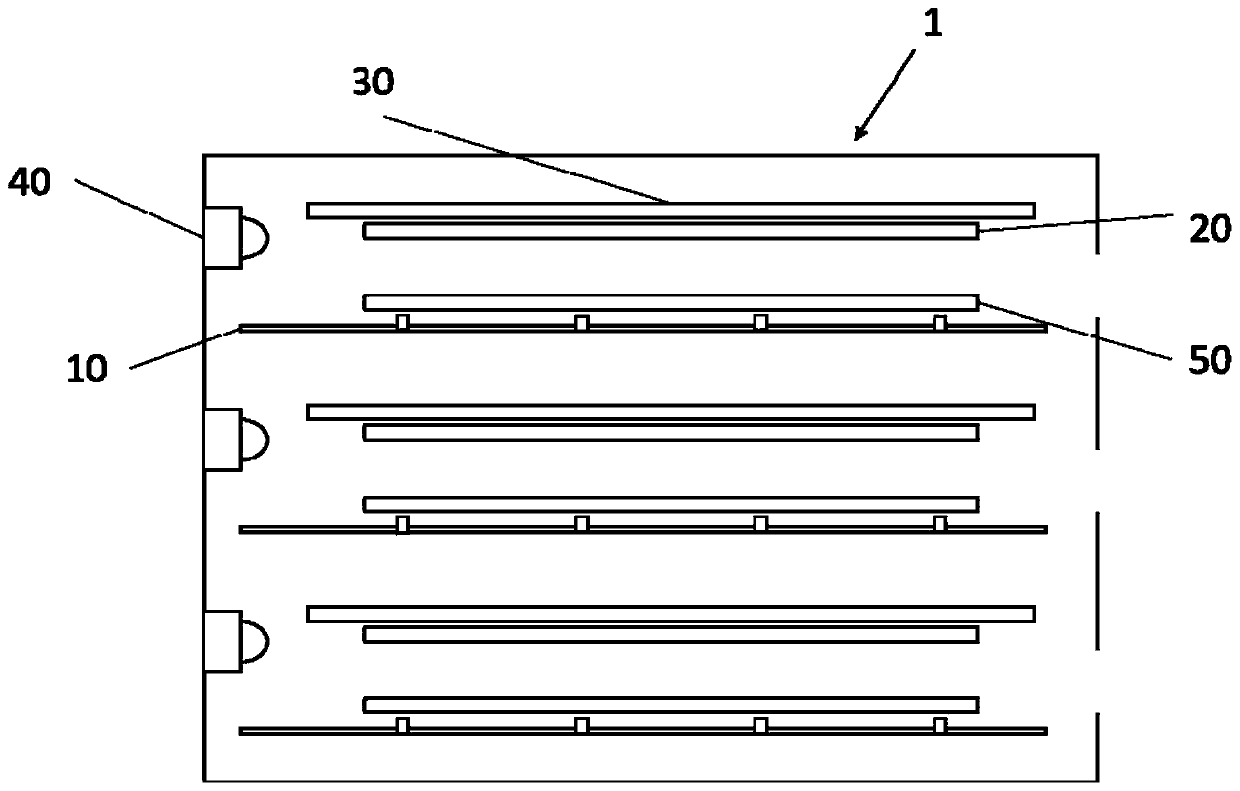

[0022] In one embodiment, a photoresist bleaching and baking device, such as figure 1 As shown, an oven 1 is included, and the oven 1 includes a plurality of heat-pressed board layers 10, a plurality of light guide plates 20, and the plurality of light guide plates 20 are arranged in the oven 1, and a plurality of reflective plates 30, the A plurality of reflective plates 30 are disposed on one side of the plurality of light guide plates 20 and are parallel to the light guide plates 30 , and a plurality of light sources 40 are disposed on the side wall inside the oven 1 .

[0023] Wherein, the plurality of light sources 40 project light on the plurality of light guide plates 20 for a period of time to perform a bleaching process, and at the same time, the plurality of hot-pressed plate layers 10 perform a hot air baking process.

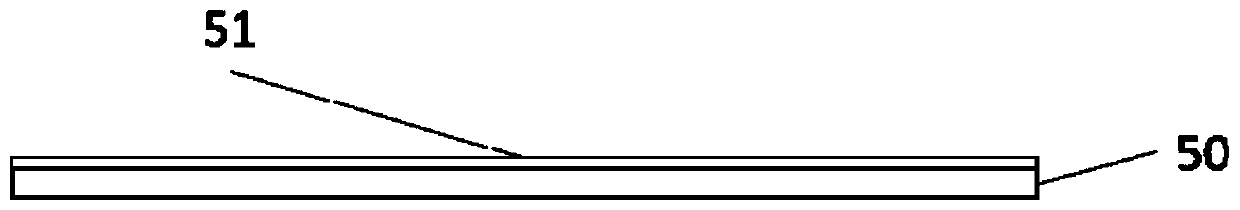

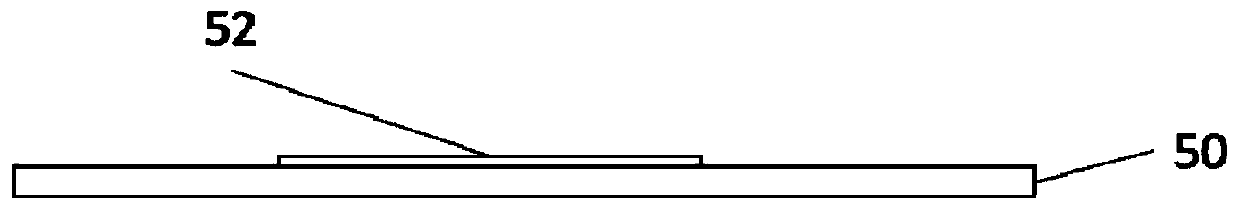

[0024] In one embodiment, as figure 2 with image 3 As shown, the oven 1 includes at least one substrate 50. The substrate 50 forms a photoresist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com