Single-motor double-shaft driving mechanism, feeding shovel-taking stir-frying device and automatic cooker of feeding shovel-taking stir-frying device

A dual-axis drive, single-motor technology, applied to cooking utensils, household appliances, applications, etc., can solve the problems of complex control structure and very high accuracy requirements, achieve low accuracy requirements, low manufacturing costs, eliminate friction and friction The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

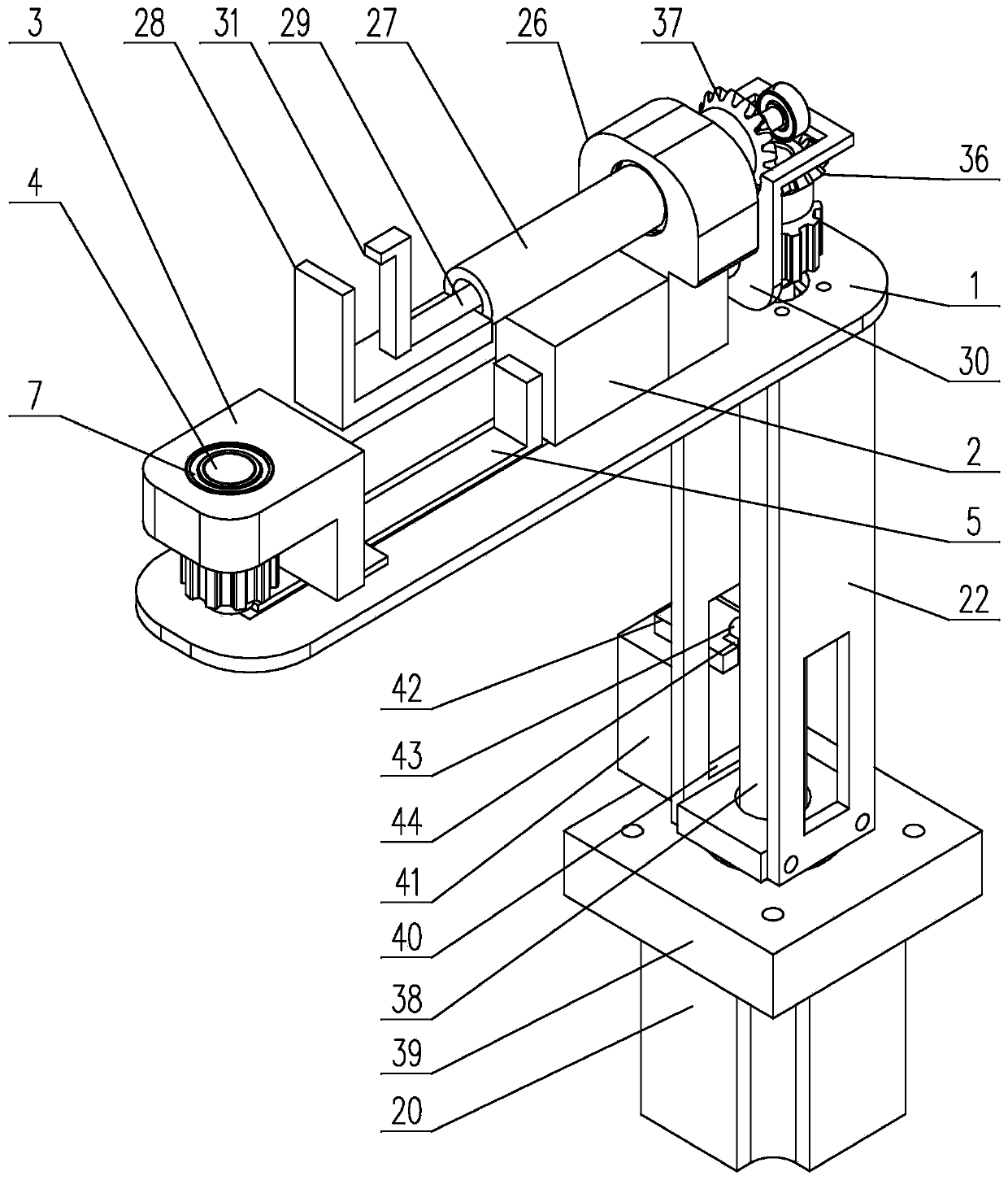

[0075] Such as Figure 1~Figure 7 As shown, a single-motor dual-axis drive mechanism of the present invention includes a vertically arranged motor 20, a Z-axis drive assembly, an X-axis drive assembly, and an adjustment assembly. A fixed seat 39 is installed at the end of the motor 20, and the motor The output shaft of 20 moves through the fixed seat 39;

[0076] The Z-axis drive assembly includes an external connecting piece 22 and a support arm 1, the external connecting piece 22 is sleeved on the output shaft of the motor 20, and its bottom end is rotatably connected to the fixed seat 39 through a bearing, and its top end is connected to the supporting arm. 1 connection, a strip-shaped relief hole 40 is provided on the lower side of the side wall of the outer connector 22;

[0077] The X-axis driving assembly includes an inner shaft 38 connected in sequence, a gear reversing transmission mechanism, a support plate 26 and a sleeve 27. Coaxial connection, the top end of whi...

Embodiment 2

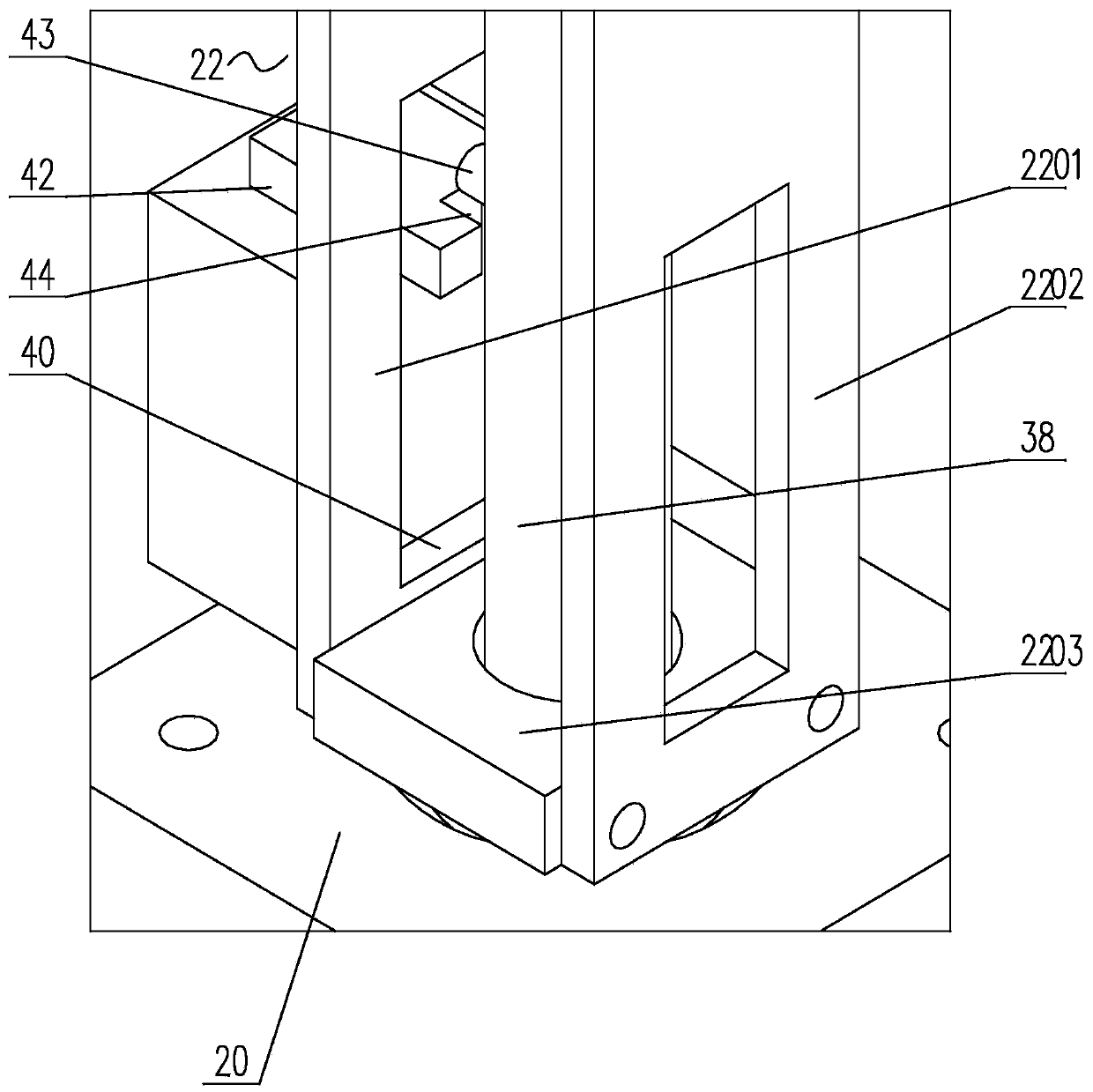

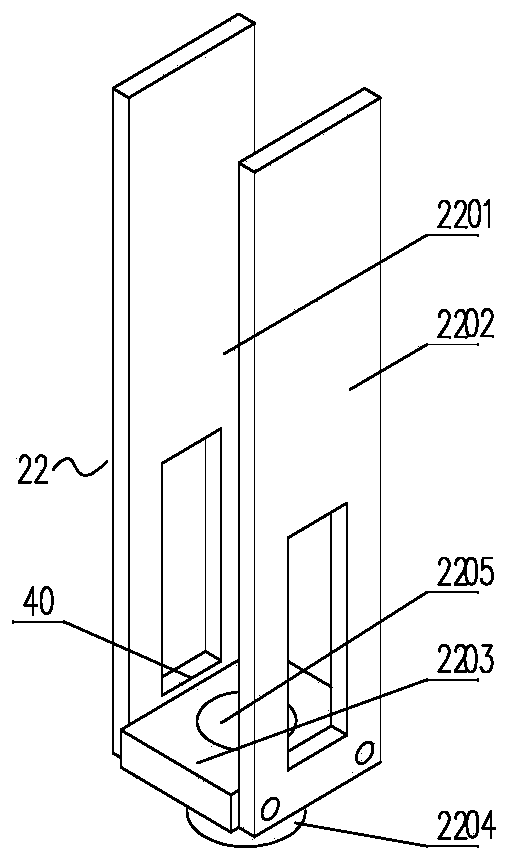

[0088] This embodiment is an illustration of the first implementation structure of the outer connecting member 22 in the first embodiment.

[0089] Such as Figure 1~Figure 3 As shown, in the present invention, the outer connector 22 includes a left vertical plate 2201, a right vertical plate 2202, a horizontal plate 2203 and a main cylinder 2204 between them, and the two sides of the horizontal plate 2203 are connected with the left vertical plate respectively. 2201, the bottom end of the right vertical plate 2202 is connected, and the horizontal plate 2203 is provided with a main through hole 2205 through which the output shaft of the power supply motor 20 can move. The axis of the main cylinder 2204 coincides with the axis of the output shaft of the motor 20. It is connected with the horizontal plate 2203, and its bottom end is inserted into the fixed seat 39, and is rotatably connected with the fixed seat 39 through a bearing. A strip-shaped relief hole 40 is provided on ...

Embodiment 3

[0093] This embodiment is an illustration of the second implementation structure of the outer connecting member 22 in the first embodiment.

[0094] Such as Figure 4~Figure 5 As shown, in the present invention, the outer connecting member 22 includes an outer cylinder 53, an engaging plate 54 and a main cylinder 2204, the axes of the outer cylinder 53 and the main cylinder 2204 coincide with the axis of the inner shaft 38, and the connecting plate 54 is a U-shaped plate, and its upper and lower side plates are respectively connected with the outer cylinder 53 and the main cylinder 2204, and the bottom end of the main cylinder 2204 is inserted into the fixed seat 39, and is rotatably connected with the fixed seat 39 through a bearing, The bottom end of the inner shaft 38 passes through the lower edge plate of the connecting plate 54 and is located in the central hole of the main cylinder 2204, and is connected with the output shaft of the motor 20, and its top passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com