Device for removing paint mist

A paint mist and adjusting device technology, which is applied in the directions of grease/oily substance/float removal device, combination device, and dispersed particle separation, etc., can solve the problems of increased humidity in the spray paint space, easy blockage of the filter device, and high treatment cost. Easy to maintain and operate, to solve the effect of easy clogging, to improve removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

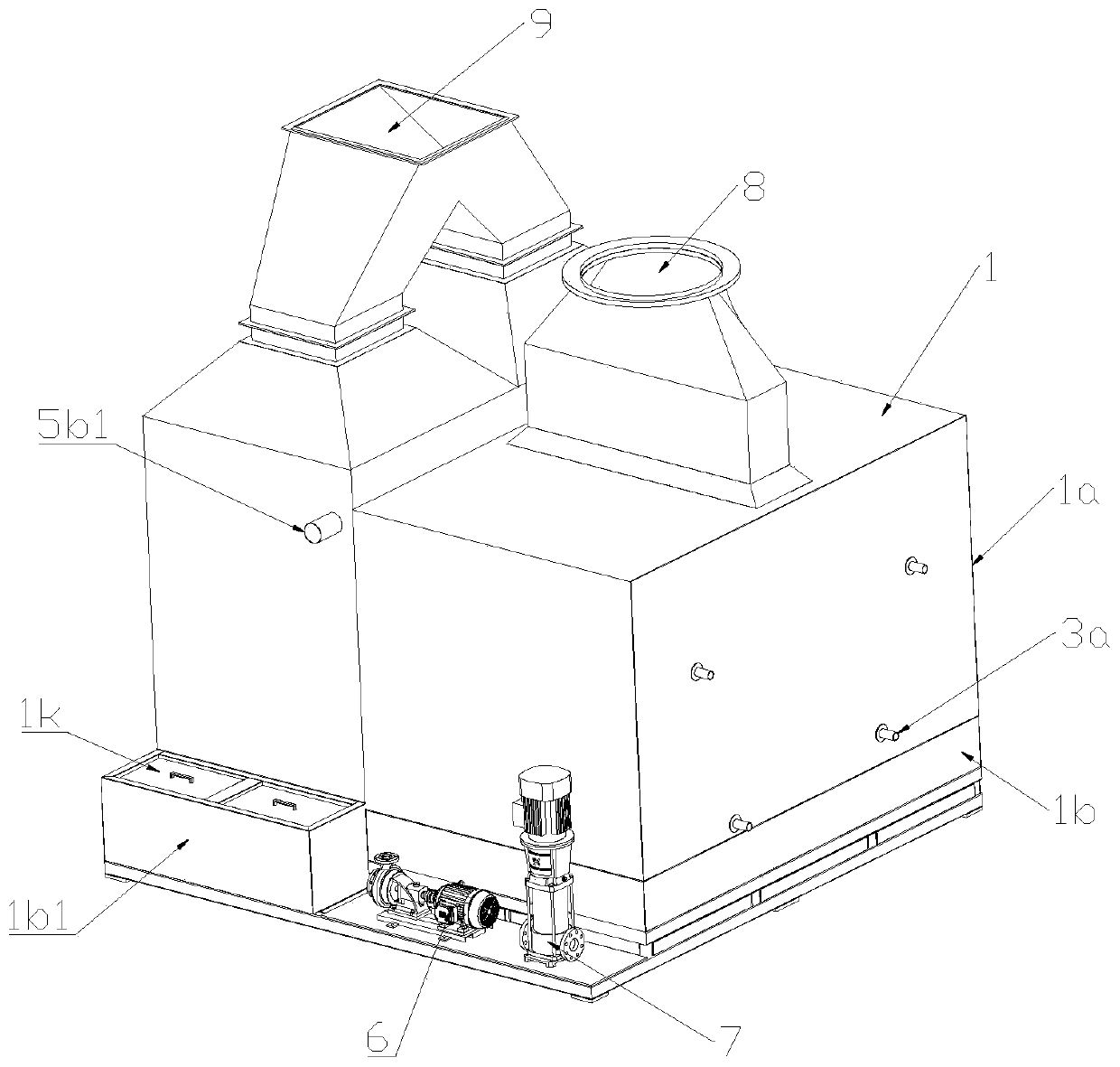

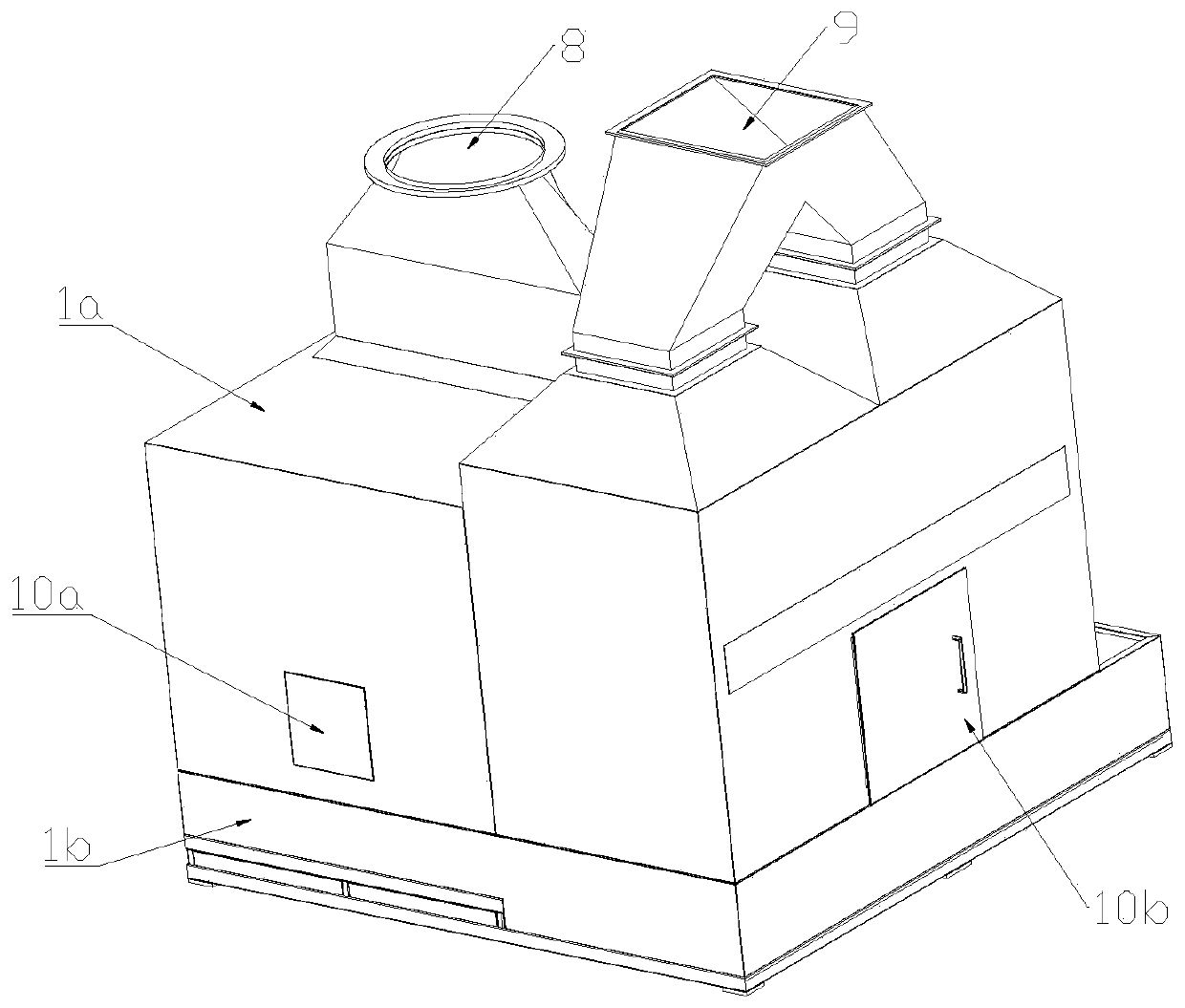

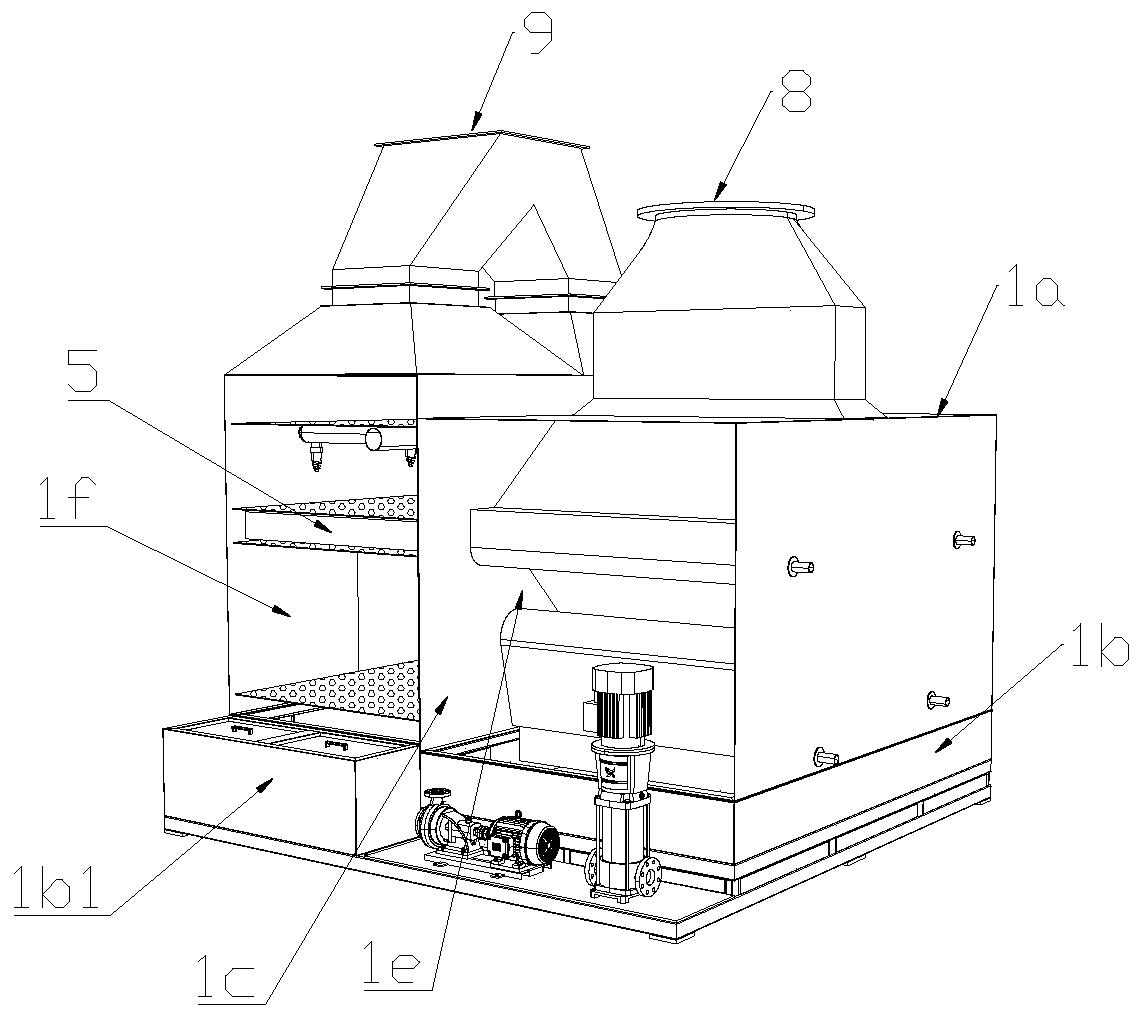

[0050] Such as Figure 1-9 A device for removing paint mist is shown, which is mainly used in the treatment of waste gas discharge in chemical enterprises, including casing 1, flow guide mechanism 2, water spray device 3, adjustment device 4, filter device 5, waste water pump 6, centrifugal pump 7. Exhaust gas inlet 8, exhaust gas outlet 9 and maintenance area 10.

[0051]The casing 1 includes an upper casing 1a and a lower casing 1b distributed up and down. A gasket 1d is connected between the upper casing 1a and the lower casing 1b to ensure the sealing of the casing 1. The inner space of the casing 1 is divided into two parts by a partition 1c. The first chamber 1e and the second chamber 1f, the partition 1c is provided with a plurality of through holes 1g for communicating the first chamber 1e and the second chamber 1f, and the through holes 1g are located in the lower casing 1b, both Make sure that the water in the first chamber 1e and the second chamber 1f can communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com