Method for removing center line shrinkage and controlling center segregation of 280mm*320mm fracture surface high-carbon steel

A technology of central shrinkage cavity and control center, which is applied in the field of continuous casting in the metallurgical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

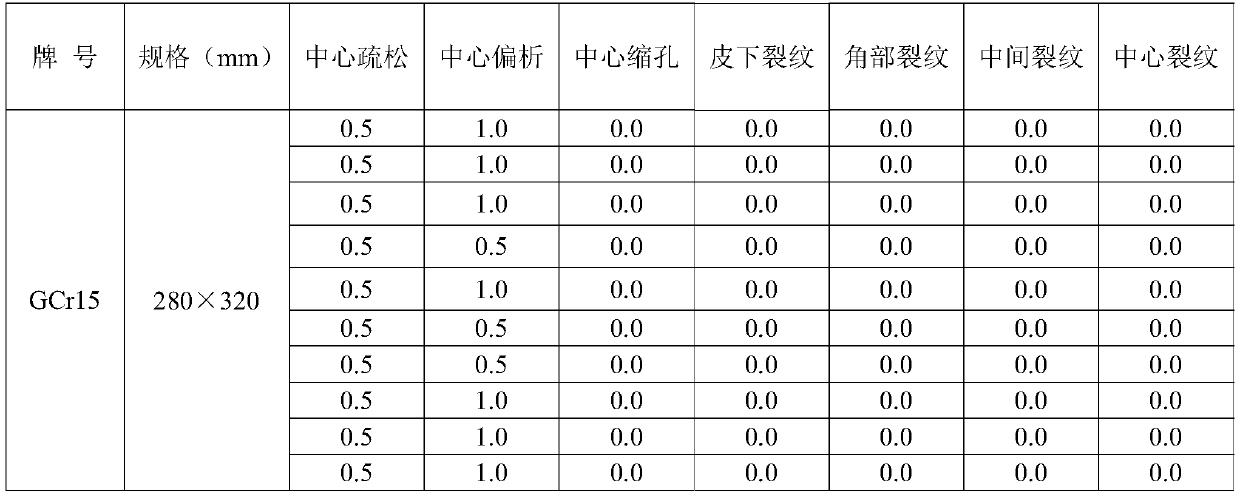

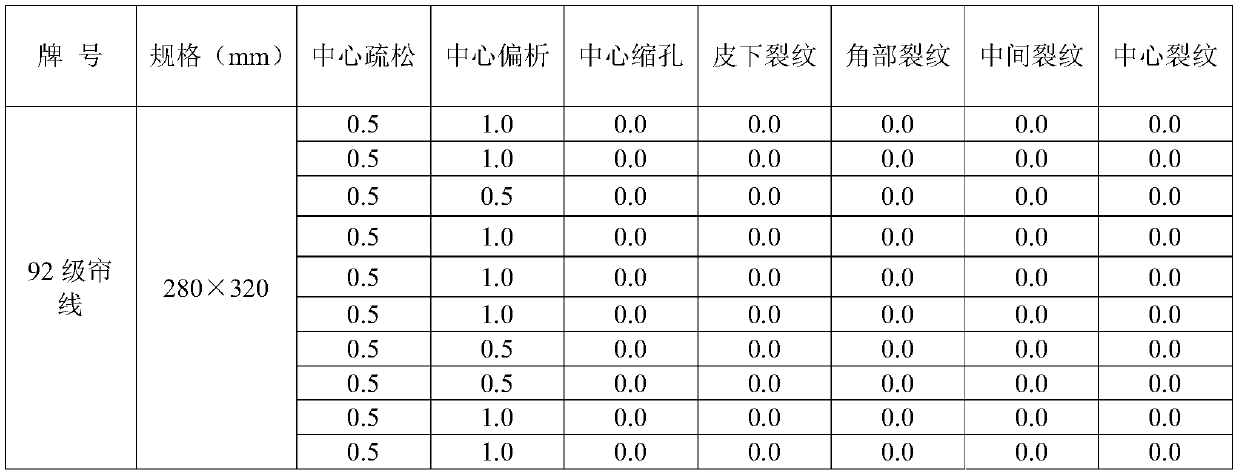

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with embodiment:

[0012] The present invention will be described in further detail below in conjunction with specific examples.

[0013] The soft reduction technology implements multi-roll continuous rolling in the section where the solid phase ratio in the mushy zone of the slab is 0.3-0.8 (the proportion of the solid phase in the mushy zone, when the solid phase ratio is 1, it is equivalent to the complete solidification of the slab). Improve the center segregation of the slab with a small reduction, or adopt heavy reduction technology at the end of solidification, aiming to apply a large reduction in the range of solid phase ratio of 0.8-1.0 in the mushy area of the slab to solve the problem of shrinkage cavity in the core of the slab, but looking for To the real position of the coagulation end is the focus of implementing this technology. In the production of high carbon steel, the mushy z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com