A Split Drilling Tool Connection Structure for High-Speed Machining

A drilling tool and connecting structure technology, applied in the field of split drilling tool connecting structure, can solve the problems of asymmetric overall structure, reduce the strength of the connecting structure, limit the drilling speed, etc., to ensure accuracy and circumferential strength, Improve the overall dynamic balance and avoid the effect of tool eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

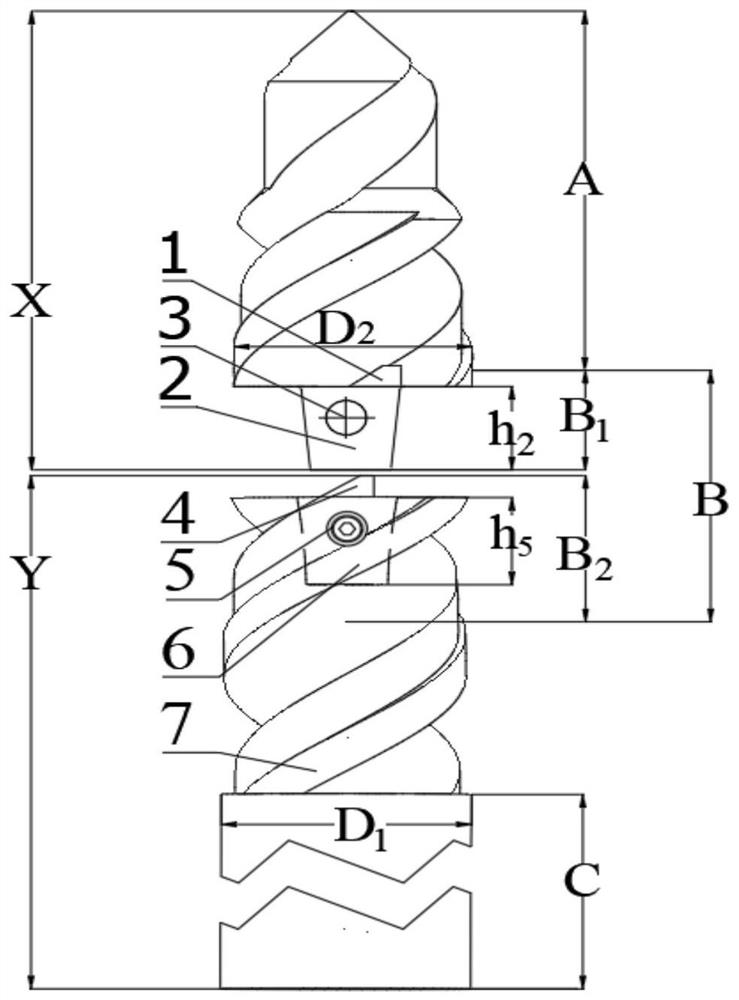

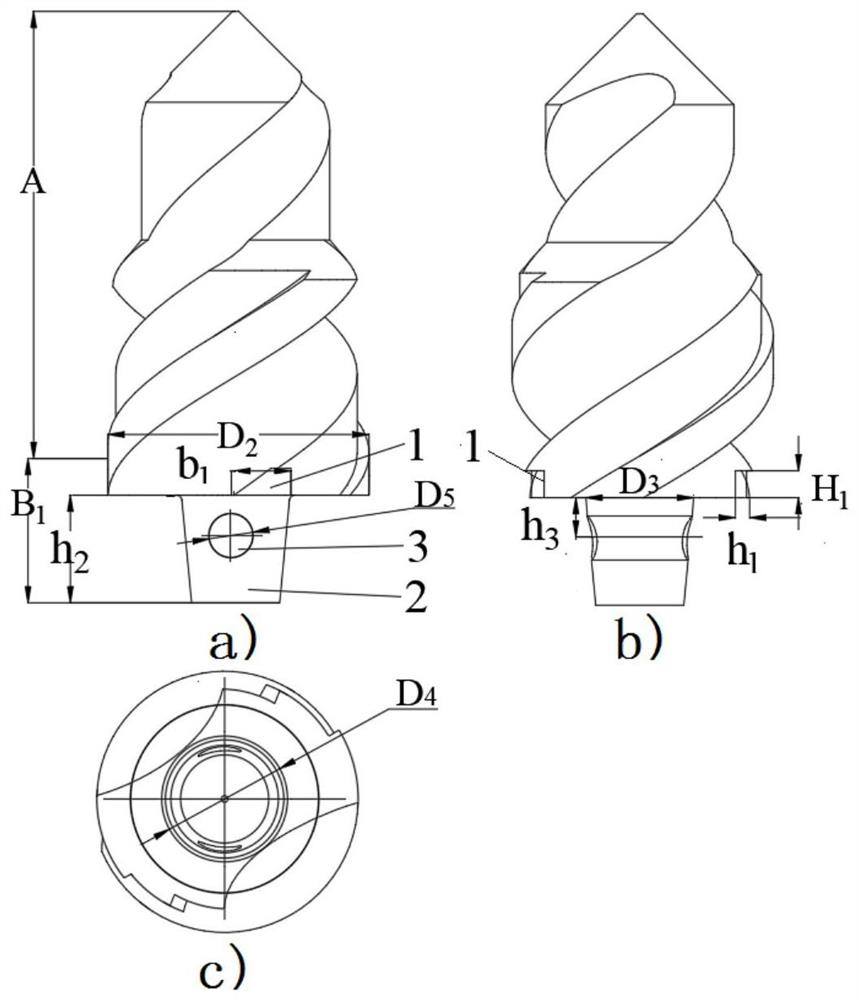

[0017] Specific embodiment 1, using CFRP as the material to be processed, the cutting part A adopts a double-stepped micro-tooth structure, the first step diameter is 7mm, the drill tip angle is 90°, the length is 8.5mm, and the second step diameter is the final hole diameter D 2 =10mm, the apex angle of the second stepped cutting edge is 90°; core thickness D 4 = 4.5 mm.

[0018] Drill tip connection part B 1 The outer profile is processed with a concave ring groove 1 and a conical frustum 2, and the thickness of the concave ring groove is h 1 =0.5mm, width b 1 =2mm, depth H of concave ring groove 1 = 1mm. A round hole 3 is processed on the frustum 2, and the diameter D of the large circle of the frustum 2 is 3 =4mm, height h of frustum 2 2 =4mm, the centerline of the circular hole 3 and the large circle diameter D of the frustum of the cone 2 3 distance h 3 = 2mm, the taper of the truncated cone 2 is 1:6, and the diameter of the circular hole 3 is D 5 = 1.6 mm.

[...

specific Embodiment 2

[0022] Specific embodiment 2, with the CFRP / aluminum alloy laminated structure as the material to be processed, the tool tip X is a combination of 120° and 140° double-vertex angle drill tip form, and the diameter of the final hole is D 2 = 10mm;

[0023] Drill tip connection part B 1 The outer profile is processed with a concave ring groove 1 and a conical frustum 2, and the thickness of the concave ring groove is h 1 =0.5mm, width b 1 =2mm, depth H of concave ring groove 1 = 1mm. A round hole 3 is processed on the frustum 2, and the diameter D of the large circle of the frustum 2 is 3 =4mm, height h of frustum 2 2 =4mm, the centerline of the circular hole 3 and the large circle diameter D of the frustum of the cone 2 3 distance h 3 = 2mm, the taper of the truncated cone 2 is 1:6, and the diameter of the circular hole 3 is D 5 = 1.6 mm.

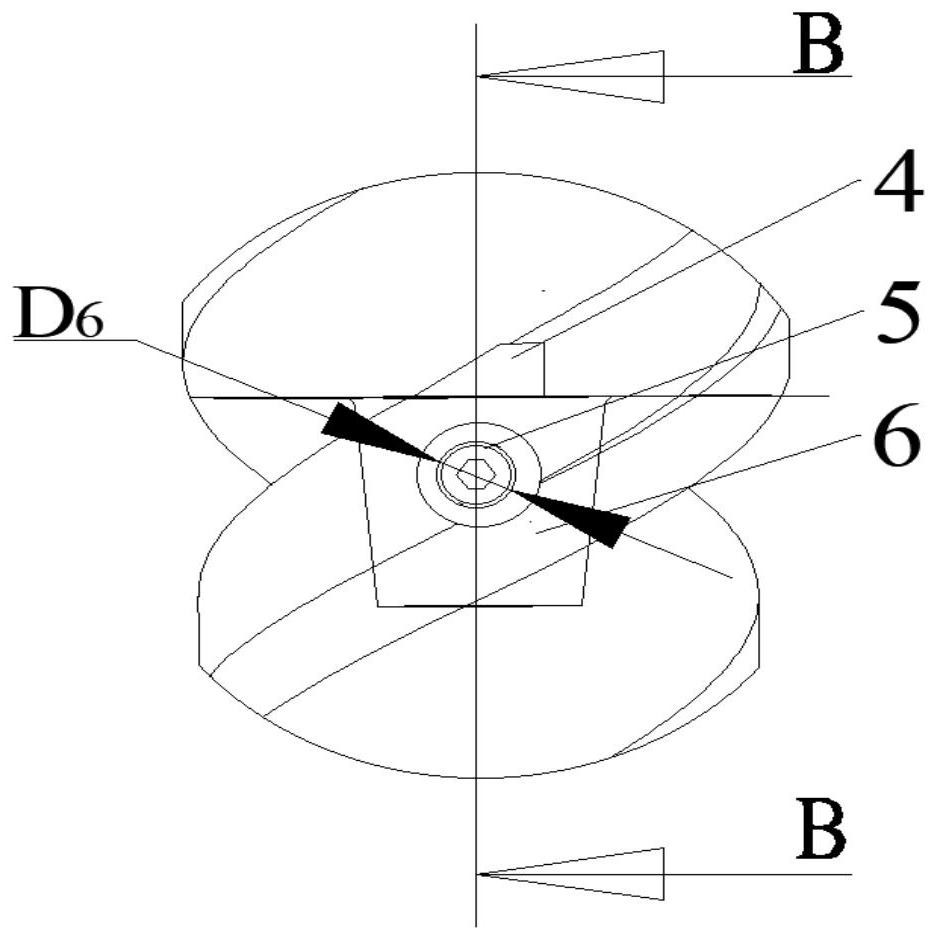

[0024] Shank connection part B 2 with B 1 Matching, the size of the boss 4 matches the groove 1, and the diameter of the left an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com