Novel container hoisting equipment

A technology for hoisting equipment and containers, applied in the direction of transportation and packaging, load hanging components, door/window accessories, etc., can solve problems such as permanent deformation, box deformation, impact, etc., and achieve the goal of improving work efficiency and operation safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

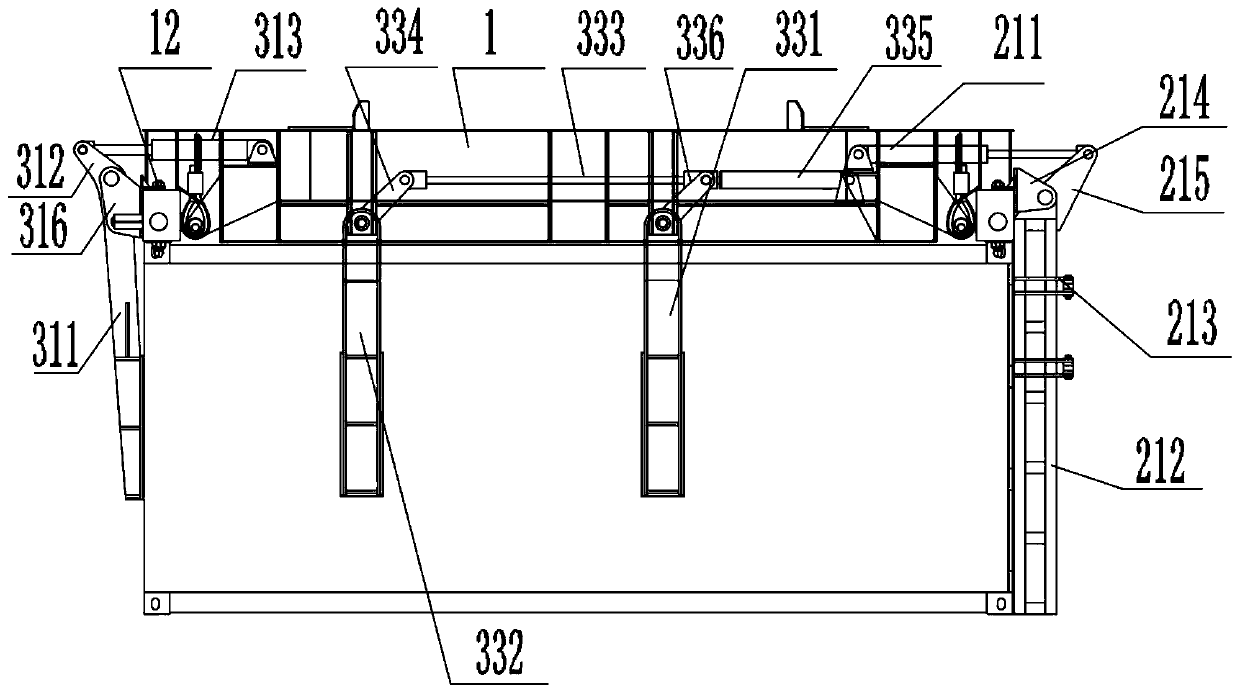

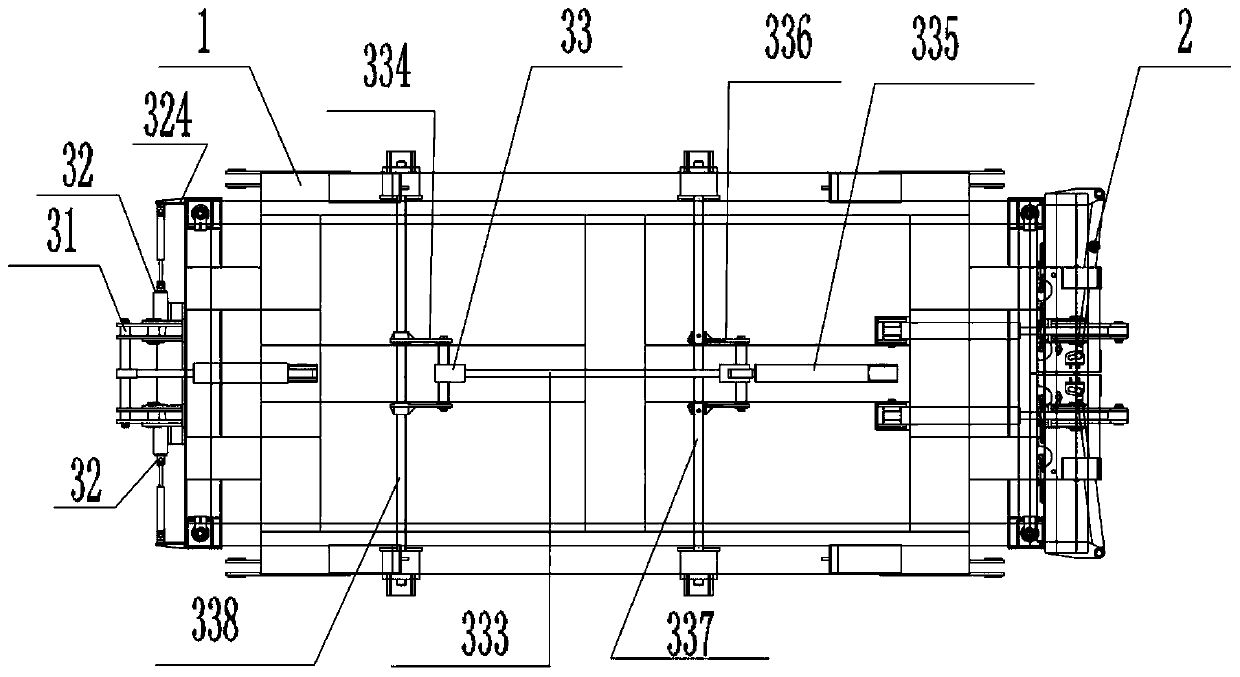

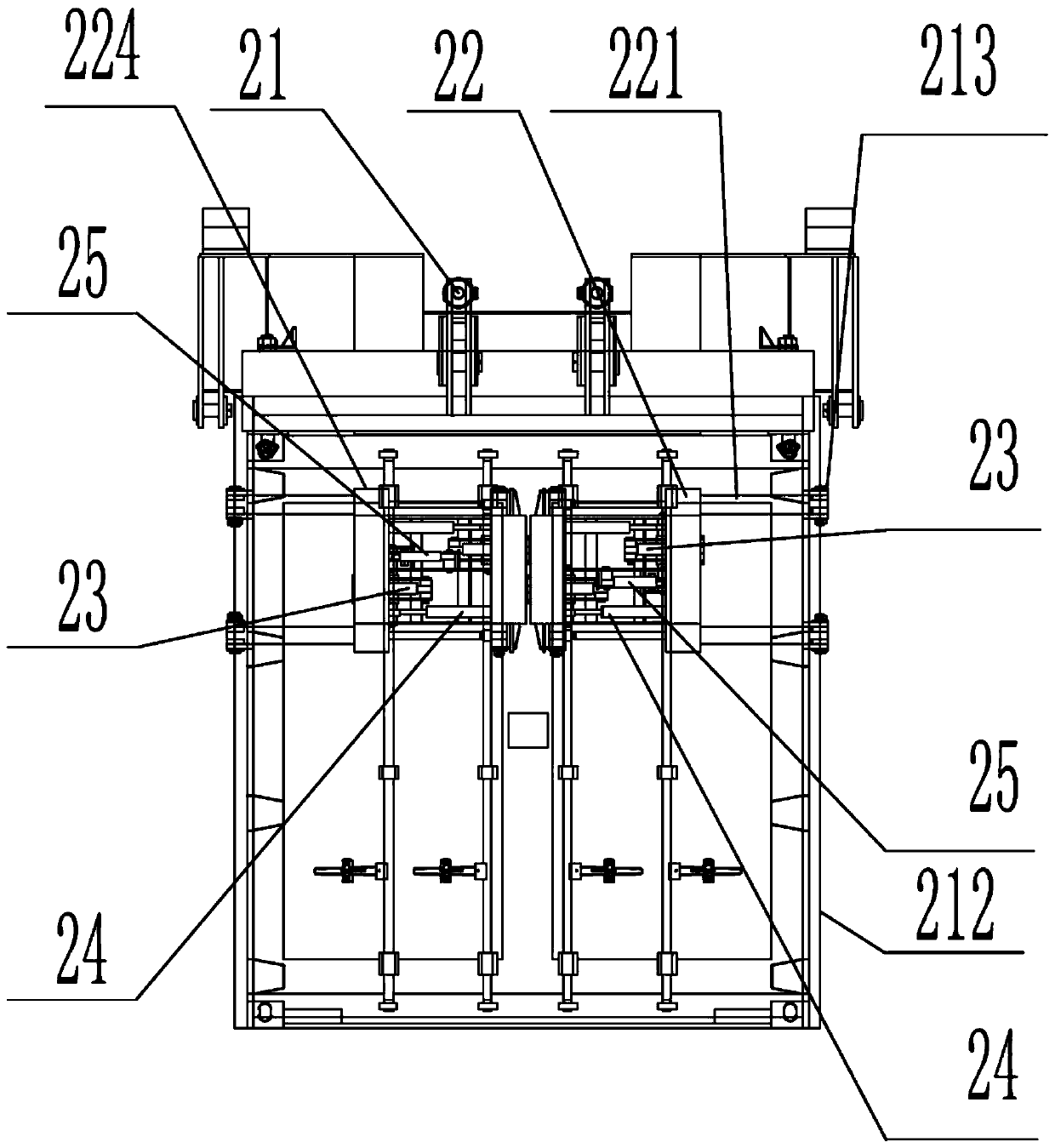

[0049] like Figure 1-Figure 23 As shown, a new type of container hoisting equipment described in this embodiment includes a spreader 1, and one end of the spreader 1 is installed with a door switch device 2 for controlling the automatic opening of the container door. A box protection mechanism 3 for compressing and protecting the outer wall of the container.

[0050] In the above structure, the spreader 11 is composed of the lifting point 111 carried by the spreader, the longitudinal beams 112 on both sides of the spreader, the connecting beam 113 in the middle, the beam 114 near the door, the beam 115 near the end of the box, the longitudinal beam 116 in the middle of the box, and the turning beam. Locking stop 117 and spreader end beam structure 118 are formed. Among them, the lifting point 111 of the spreader is the node connected to the container turning machine, and also the maximum stress point of all components and the load of the fully loaded container, which needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com