Steel slag heat treatment and method

A technology of heat treatment system and steel slag, which is applied in the direction of separation method, chemical instrument and method, combined device, etc., can solve the problems of plant structure corrosion, affecting the workshop environment, and harsh working environment, so as to improve the service life, purify the working environment, and prevent dusty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

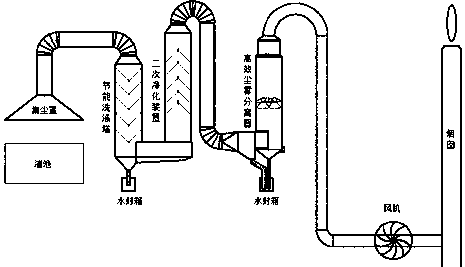

[0024] Iron and steel slag heat treatment system and method, its structure is as follows figure 1 As shown, including slag pool, dust hood and flue gas treatment mechanism, fan and chimney. The slag pool is used to treat steel and steel slag by hot-splashing gravel. The dust collection hood is set above the slag pool to suck in smoke and water vapor. The smoke treatment mechanism is connected to the dust collection hood through pipes to absorb The flue gas and water vapor are processed, and the fan is installed on the pipe connecting the flue gas treatment mechanism and the chimney, which is used to provide negative pressure for the dust collection hood to inhale the flue dust, and discharge the treated clean flue dust from the chimney.

[0025] The pipeline is made of steel and arranged on the factory column in the factory building....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap