Aerosol conveying assistant device and conveying method

An auxiliary device, aerosol technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of polluted pipeline, atmospheric pressure difference, liquid aerosol input control, etc., to achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

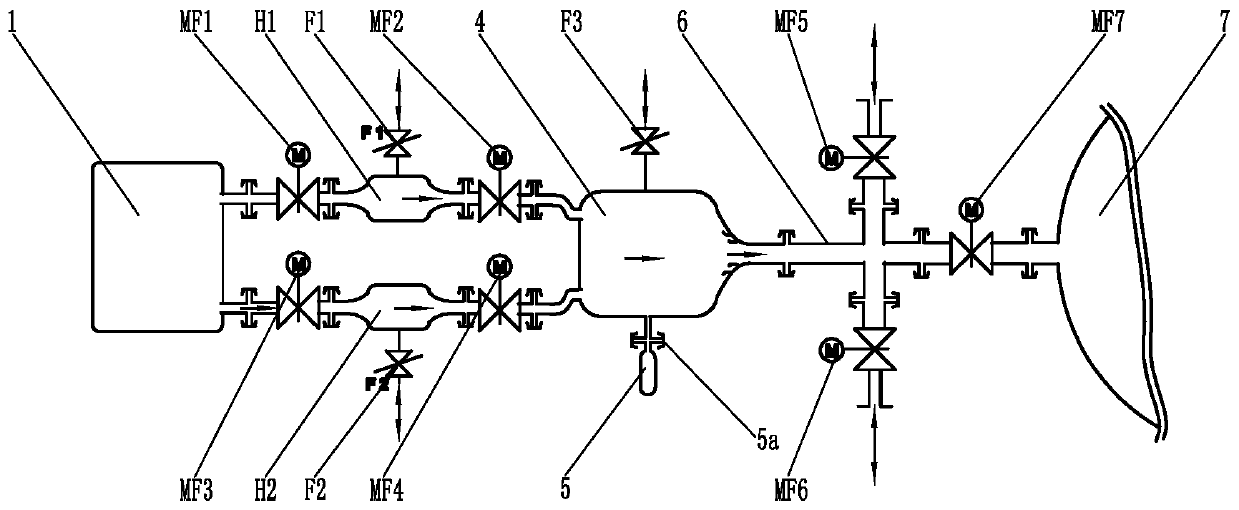

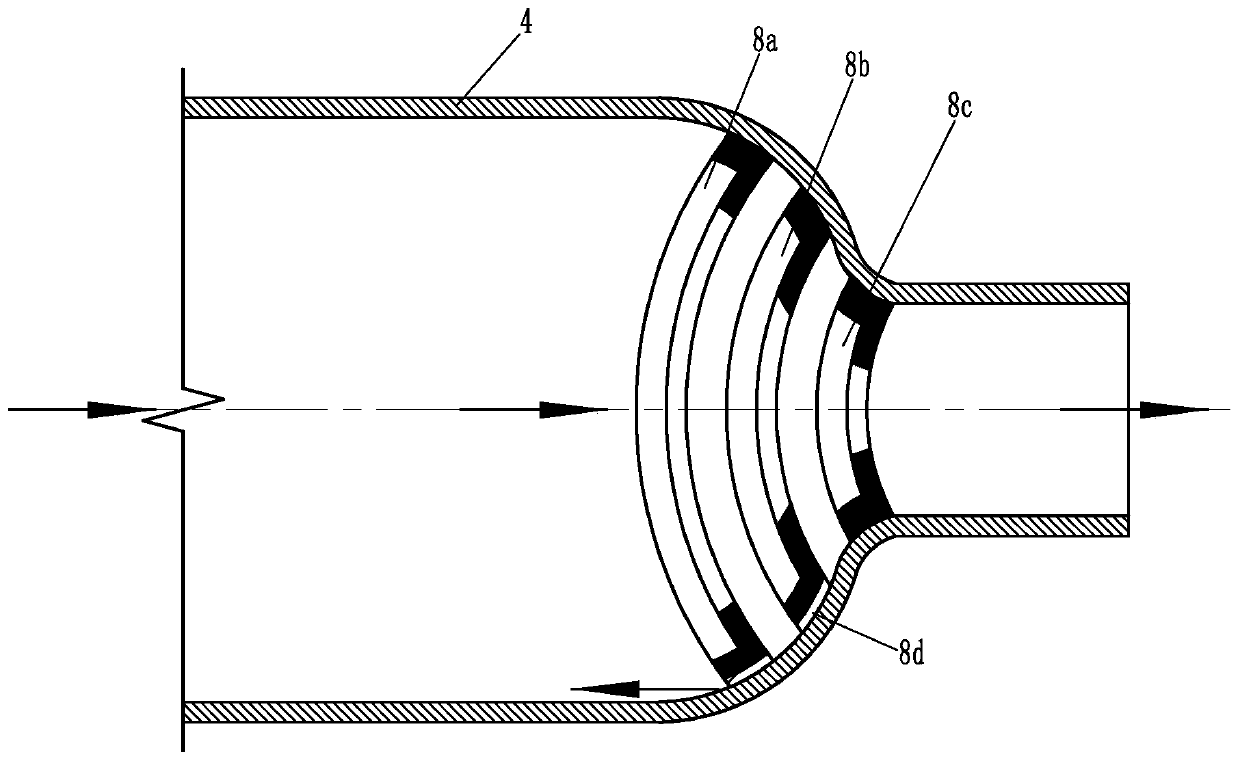

[0030] Such as figure 1 and figure 2 As shown, an aerosol transmission auxiliary device and delivery method include an atomization generator 1 , a mixing buffer chamber 4 and a cross-shaped pipe joint 6 . Among them, it should be noted that: in the field of material preparation, the atomization generator 1 is generally a device that generates liquid aerosol based on ultrasonic atomization, and the atomization amount is related to the composition, concentration, temperature and air pressure of the solution. There is a relationship, and usually a stable atomization is achieved at normal pressure.

[0031] Between the atomization generator 1 and the mixing buffer chamber 4, at least two aerosol transmission branch pipelines with the same structure are arranged in parallel. It should be noted that in this case, only two aerosol transmission branch lines with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com