Textile material cleaning device with rapid dehydrating function for spinning

A technology for textile materials and cleaning devices, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles and papermaking, etc., can solve the problem that textile materials are difficult to dry, affect the processing quality of textile materials, and prevent materials from being cleaned sufficiently. and other problems, to achieve the effect of reducing water content, increasing practicability, and reducing drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

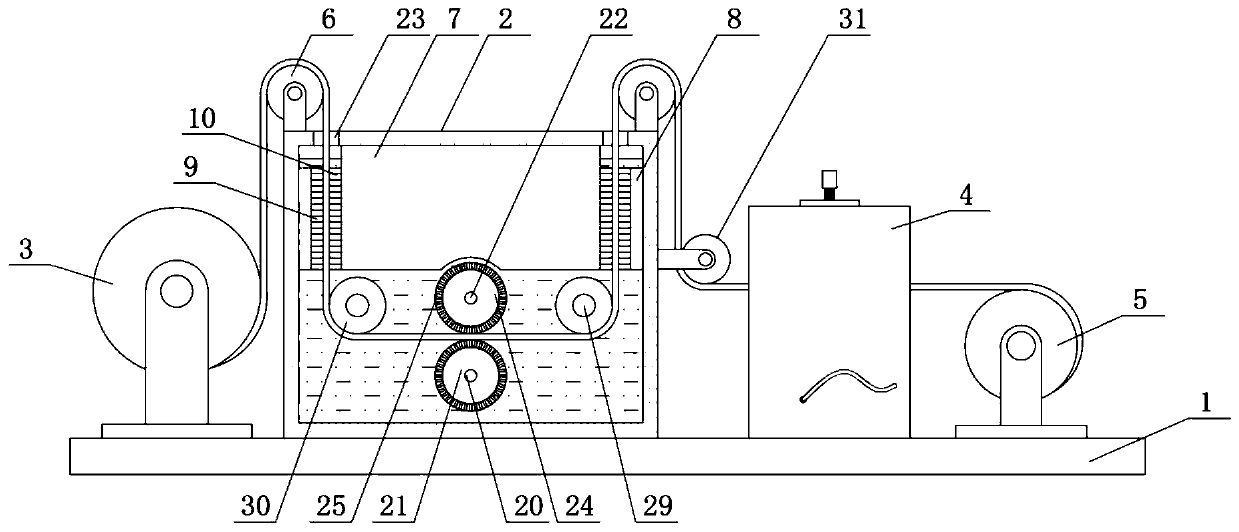

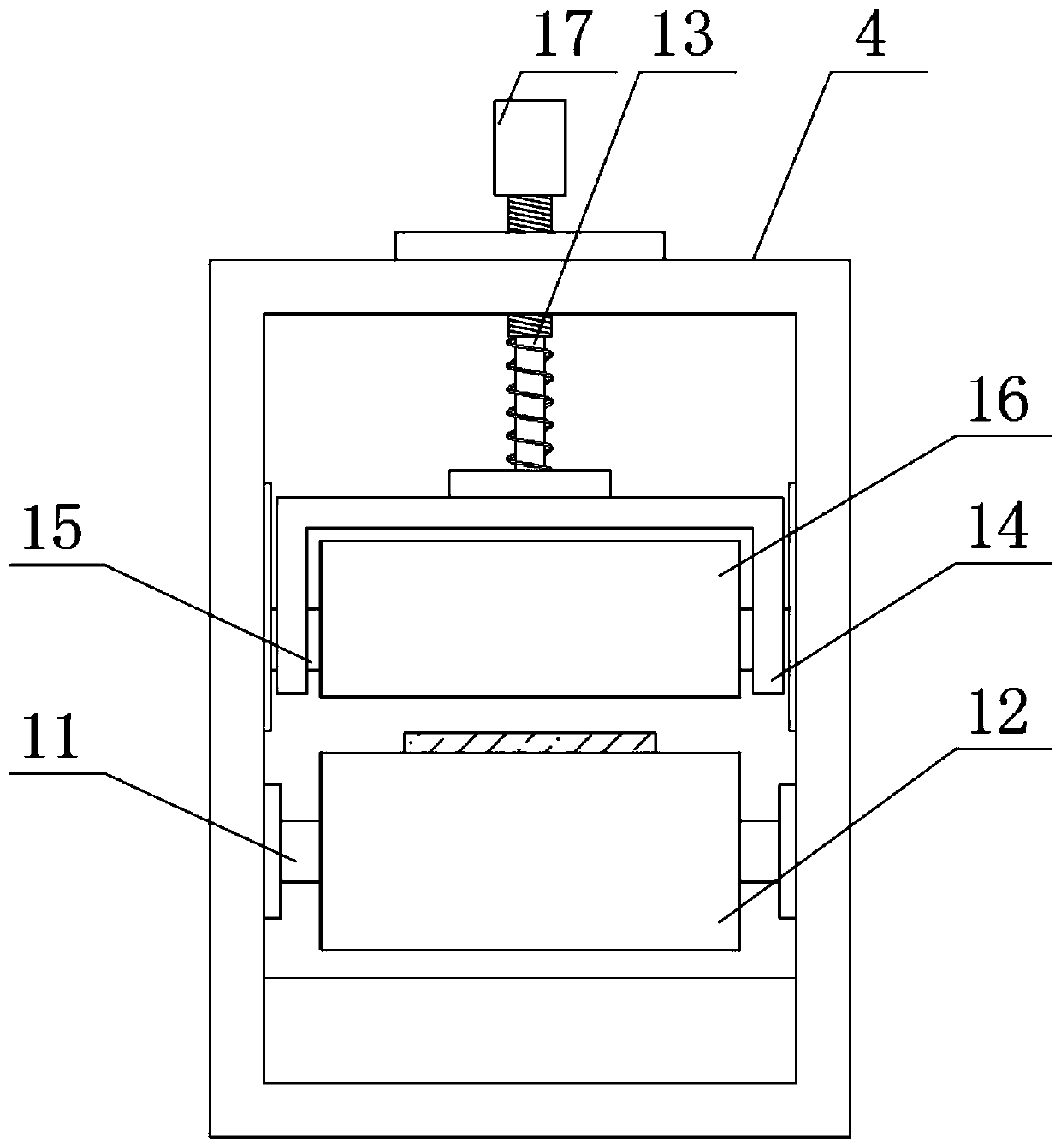

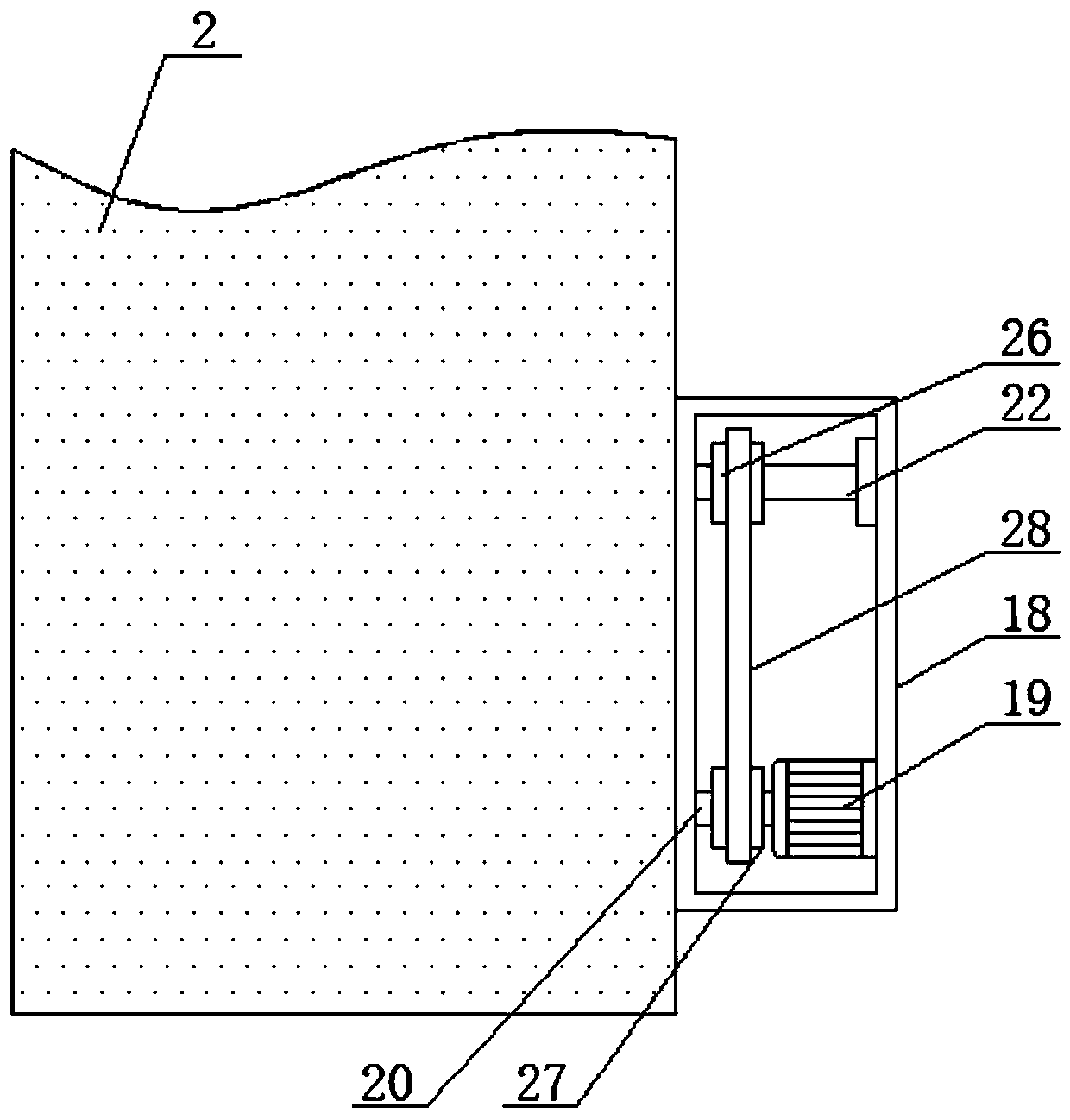

[0031] see Figure 1-5 A textile material cleaning device for rapid dehydration for textile use, comprising a base 1, a cleaning box 2 is fixedly installed on the top of the base 1, a third guide wheel 31 is fixedly installed on the right side of the cleaning box 2, and a third guide wheel 31 is fixedly installed on the top of the base 1 The winding roller 3, the top of the base 1 is fixedly installed with the extrusion box 4 on the right side of the cleaning box 2, the top of the base 1 is fixedly installed with the winding roller 5 on the right side of the extrusion box 4, and the two sides of the top of the cleaning box 2 All are fixedly installed with the first guide wheel 6, the back side of the cleaning box 2 is fixedly installed with a back box 18, the bottom of the right side of the back box 18 inner cavity is fixedly installed with a drive motor 19, and the other end of the drive motor 19 output shaft is fixedly sleeved with The rotating shaft 20, the other end of the...

Embodiment 2

[0038] Reference manual attached Figure 6 , the specific difference from Example 1 is: the 9 and 10 at the outlet of the cloth are replaced with two sets of rubber extruded blocks, and the distance between the two groups of rubber extruded blocks is less than 2-5 mm than the thickness of the cloth in the normal state.

[0039] Adopting the above-mentioned technical means: the primary dehydration of the textile material is realized, the phase rate of the subsequent dehydration is increased, the problems of difficult subsequent dehydration and excessive water accumulation are avoided, and the normal operation of the device is guaranteed.

[0040] When working, the operator first rotates the rotary block 17, so that the top force rebounding member 13 drives the second pressure roller 16 to descend through the installation frame 14, and finally through the cooperation between the second pressure roller 16 and the first pressure roller 12, thereby The textile material is extruded,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com