Continuous miner drilling-type paste filling mining method for end slope coal

A paste filling and mining method technology, applied in drilling equipment and methods, fillings, ground mining, etc., can solve the problems of poor filling rate and roofing effect, destruction of ecological environment in mining areas, and low resource recovery rate, etc. The effect of high coal extraction rate, protection of ecological environment and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

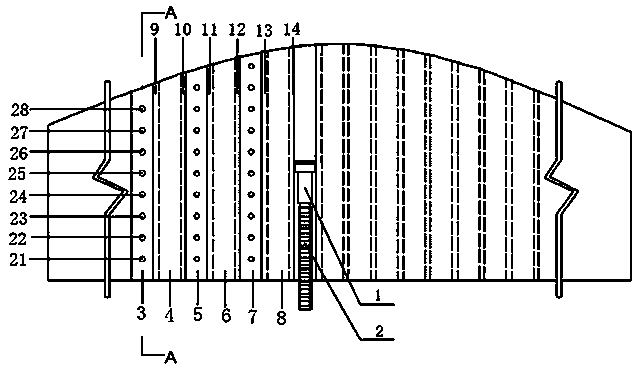

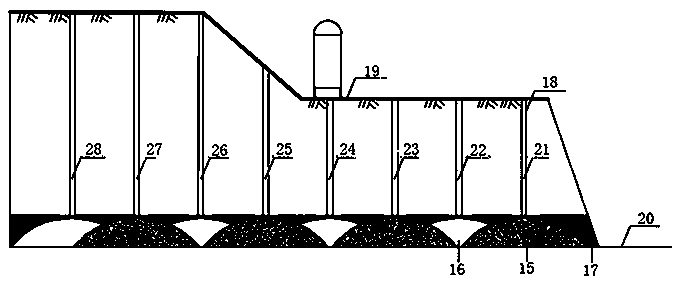

[0020] The present invention will be further described in conjunction with the accompanying drawings.

[0021] Working face parameters: This method is suitable for coal seam thickness 1.3m~5.5m, coal seam inclination angle ±6°, mining tunnel penetration depth ≤300m, mining tunnel width 3.3m, coal pillars between mining tunnels 0.5m~1.5m, medium and stable above Roof, the condition that coal pressing depth is ≤100m. Drilling parameters: drilling spacing 15m~25m, hole diameter 350mm~450mm.

[0022] 1. The overall layout of the roadway, firstly, divide the side coal pressing into several sections, and divide the section into multiple mining tunnels equal to the width of the cutting part of the continuous miner, namely mining tunnel-3, mining tunnel Two 4, mining tunnel three 5, mining tunnel four 6, mining tunnel five 7, mining tunnel six 8. Coal pillars between mining tunnels are set up in the mining tunnels, which are coal pillars 1 between mining tunnels, coal pillars 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com