Liquid crystal module hole inner wall light leakage detection method and device

A liquid crystal module and detection equipment technology, applied in the direction of optical instrument testing, optics, measuring devices, etc., can solve the problems of increasing the size of the equipment, being invisible, and bulky, and achieving the reduction of occupied space, convenient adjustment, and adaptability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] see Figure 4 , a method for detecting light leakage on the inner wall of a liquid crystal module hole of the present invention, comprising the following steps:

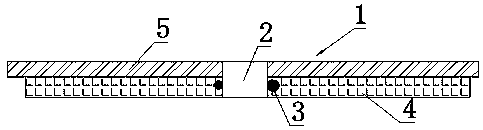

[0044] (1) Lay the liquid crystal module 1 under test flat, so that the round hole 2 of the liquid crystal module 1 under test faces the detection direction;

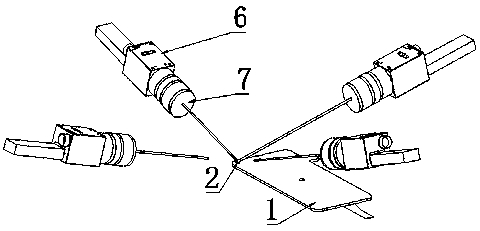

[0045] (2) In the detection direction of the round hole 2 of the liquid crystal module 1 under test, a mirror 8 and a CCD camera 6 are arranged in sequence; when there is a light leakage defect 3 on the side wall of the round hole 2, the light at the part of the light leakage defect 3 passes through the mirror After the reflection of 8, enter in the optical lens 7 of CCD camera 6;

[0046] (3) The CCD camera 6 takes photos, and performs image processing through the image processing module of the computer to judge whether there are image features generated by the light leakage defect 3 in the photos, and then judge whether there is a light leakage defec...

Embodiment 2

[0059] see Figure 4 , a detection device for detecting light leakage on the inner wall of the liquid crystal module hole of the present invention for realizing the above method for detecting light leakage on the inner wall of the hole of the liquid crystal module, comprising a CCD camera 6 and a mirror 8, and the mirror 8 is arranged on the liquid crystal module to be tested Above the circular hole 2 of 1, the CCD camera 6 is arranged above the reflector 8; when there is a light leakage defect 3 on the side wall of the circular hole 2, the light at the position of the light leakage defect 3 is reflected by the reflector 8 and enters the CCD The optical lens 7 of the camera 6 is easy to adjust, low in cost and small in space, and the CCD camera 6 or the optical lens 7 is not easy to interfere with the liquid crystal module 1 under test.

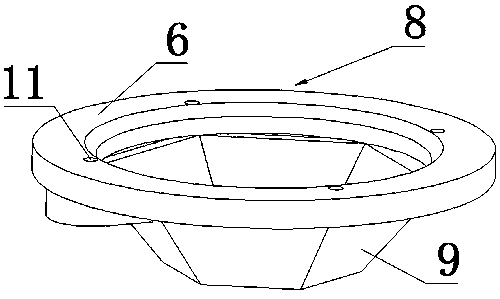

[0060] see Figure 4-5 , the reflector 8 includes an annular mirror surface 9, the radial size of the annular mirror surface 9 gradually in...

Embodiment 3

[0069] see Figure 7 The difference between this embodiment and Embodiment 2 is that in the detection device for light leakage on the inner wall of the liquid crystal module hole in this embodiment, the mirror surface of the annular mirror 9 is a curved surface, and the transverse section of the annular mirror 9 is a circle. shape.

[0070] Other implementations of this embodiment are the same as those of Embodiment 2 except for the above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com