A cold rolling rolling oil recovery pretreatment device

A pretreatment device and cold rolling technology, applied in the field of cold rolling, can solve the problems of photochemical pollution, difficult cleaning, increased oil concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

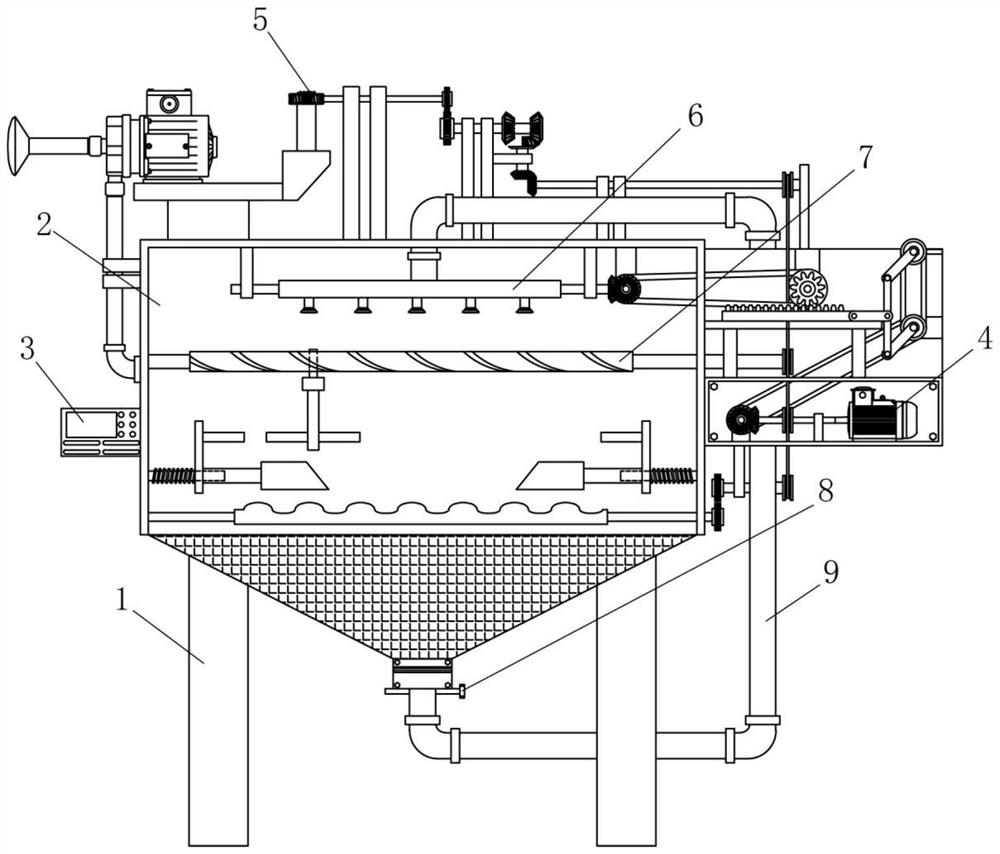

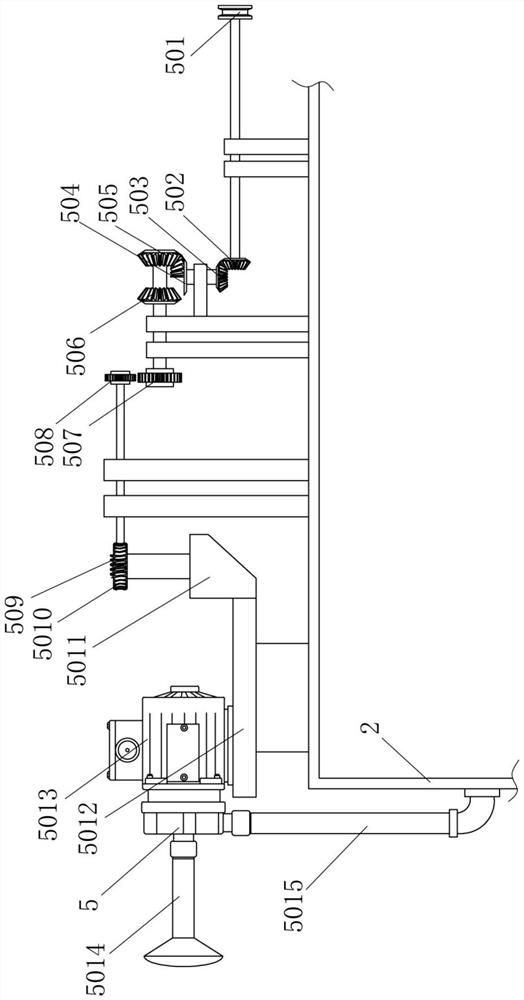

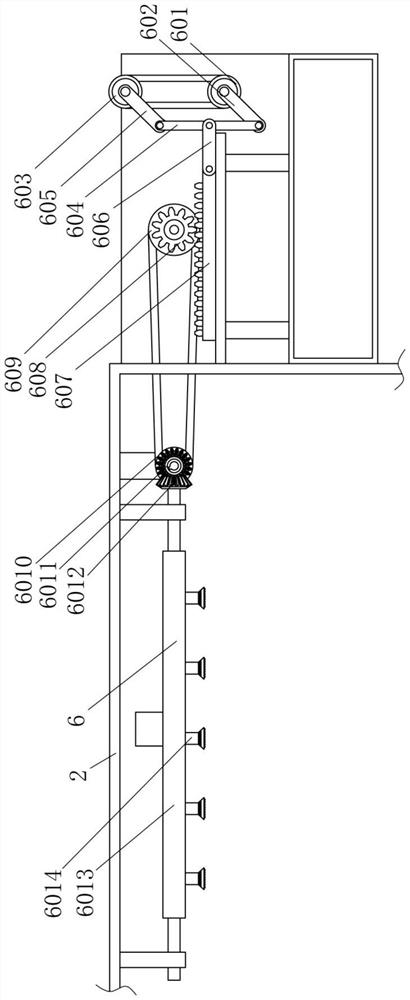

[0025] Cold rolling oil recovery pretreatment device, such as Figure 1-5As shown, including the support frame 1, the oil mist collection, the control screen 3, the motor 4, the oil mist collection mechanism 5, the oil mist settling mechanism 6, the oil mist aggregation mechanism 7, the switch valve 8, and the infusion tube 9; support frame 1 The top and right of the top are connected to the oil mist collection. The bottom of the oil mist collection compartment 2 is provided with a control screen 3; the oil mist collection compartment 2 is provided with a motor 4; oil mist collection compartment 2 top Oil mist collection mechanism 5; oil mist settling mechanism 6 is provided in the right top of the oil mist collection, and the oil mist assembly mechanism 7 is disposed in the middle portion of the oil mist collection compartment 2, and the middle portion of the oil mist aggregation mechanism 7 is connected to the motor 4 Moreover, and the top of the oil mist aggregation mechanism 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com