Tubular reactor device

A tube-and-tube reactor and reaction layer technology, applied in the field of reactors, can solve the problems of pipeline leakage, many pipeline connection nodes, and uneven heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

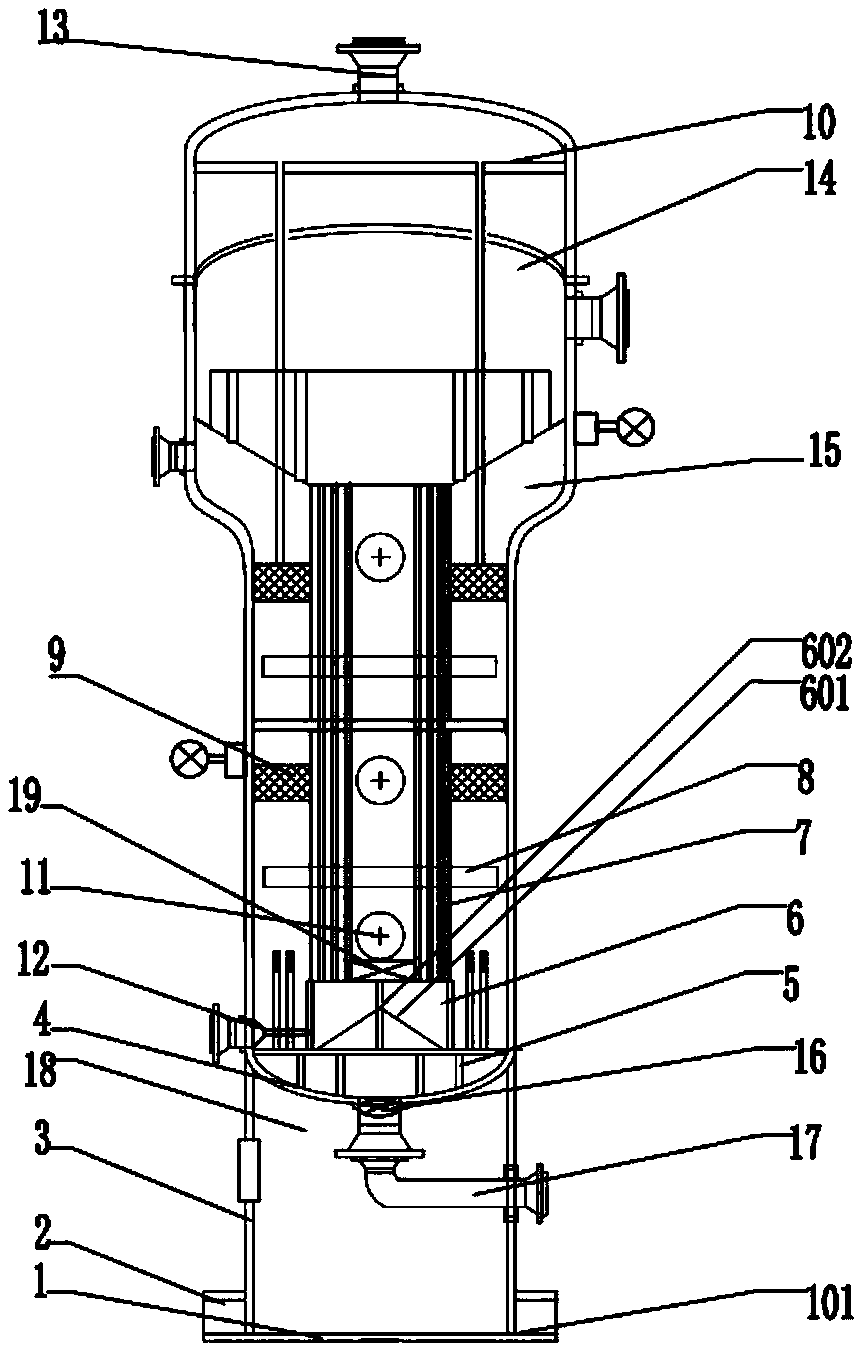

[0013] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention. A tube-and-tube reactor device as shown in the figure, including: a base plate 1, 2 sets of support pads, a cylinder body 3, a piping system, and a flange set; the base plate 1 is fixedly installed on the bottom of the device, on the base plate 1 A base ring 101 is provided, and 2 sets of support pads are fixedly installed on the bottom plate 1. Two support pads 2 are distributed on both sides of the device and fixedly connected with the base ring 101 at the bottom, and a cover plate is installed on it, and the cylinder body 3 is fixedly installed. On the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com