Low carbon alkane aromatization method

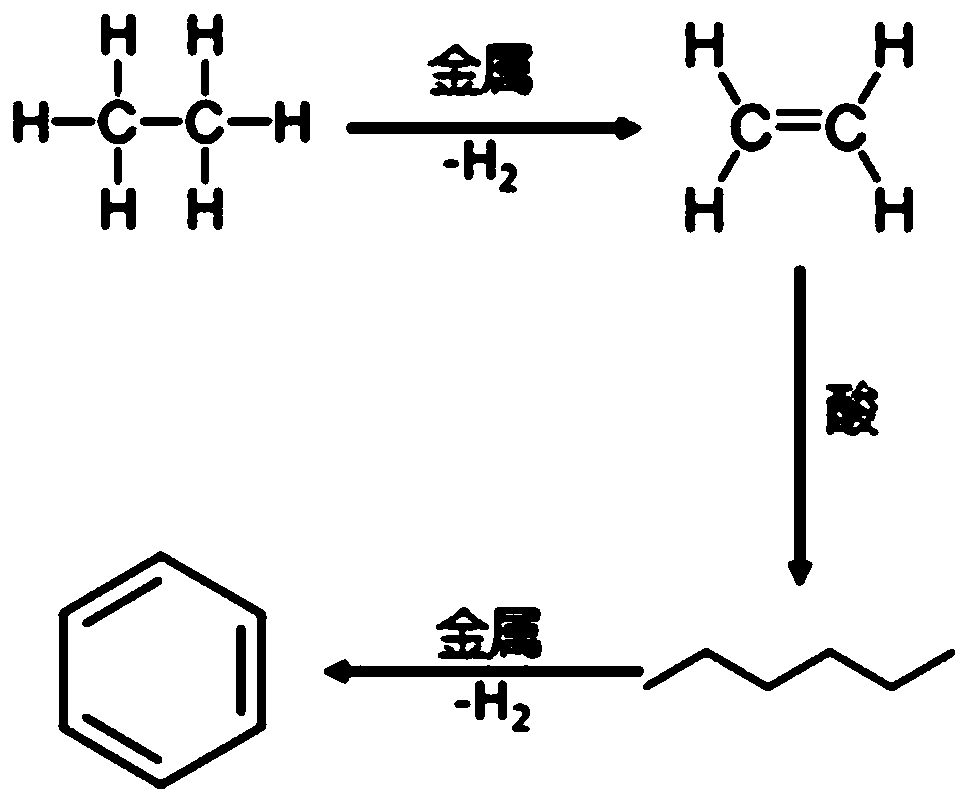

一种低碳烷烃、芳构化的技术,应用在化学仪器和方法、碳氢化合物、碳氢化合物等方向,能够解决催化剂机械强度差、无法在工业上获得应用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

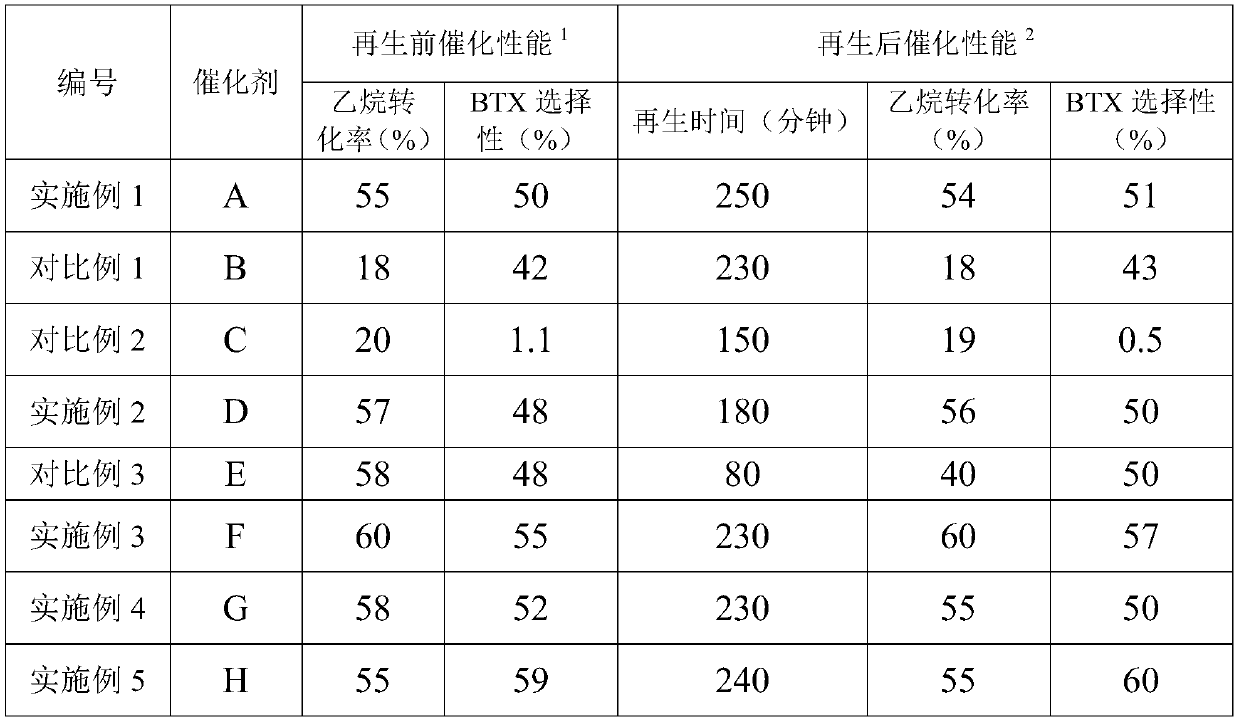

[0057] ZSM-5 powder was mixed with 0.05% by weight of Pt(NO 3 ) 2 aqueous solution mixed. The mixture was impregnated at room temperature for 1 hour, then heated to 80° C. in a rotary evaporator to obtain a dry product, followed by calcination at 300° C. for 3 hours. The resulting calcined product and Al 2 o 3 Mix according to 70:30 and extrude, bake at 550°C for 2 hours. The catalyst, denoted Catalyst A, contained 500 ppm Pt.

[0058] It can be seen from the elemental mapping image that 90% of Pt is distributed on the zeolite, and the ratio of this percentage to the percentage of zeolite in the carrier is 90% / 70%=1.29.

preparation example 2

[0065] Combine ZSM-5 powder with Al 2 o 3 Mixed and extruded at a mass ratio of 70:30, then calcined at 550°C for 2 hours, and the resulting calcined product was treated with 0.05% by weight of Pt(NO 3 ) 2 The aqueous solution was subjected to ion exchange (the volume ratio of the product to the solution amount was 1:5), stirred at a temperature of 35° C. for 2 hours, and then separated into solid and liquid. The resulting product was washed with water to remove the physical adsorption on ZSM-5 and Al 2 o 3 Pt on 2+ . Finally, the ion-exchanged product was dried overnight (8 hours) at 90°C in air, followed by calcination at 550°C for 3 hours to obtain a catalyst. The catalyst, denoted Catalyst D, contained 500 ppm Pt.

[0066] It can be seen from the elemental mapping image that 85% of Pt is distributed on the molecular sieve formed by zeolite, and the ratio of this percentage to the percentage of zeolite in the carrier is 85% / 70%=1.21.

preparation example 3

[0071] Mix ZSM-5 powder with colloidal silica and fumed silica at a mass ratio of 70:20:10, dry and shape it, then bake at 550°C for 2 hours, crush and sieve to obtain 20-40 mesh particles; after that The resulting particles were mixed with 0.05 wt% Pt(NO 3 ) 2 The aqueous solution was mixed, and the resulting mixture was impregnated at room temperature for 1 hour, then heated to 80° C. in a rotary evaporator to obtain a dry product, and calcined at 550° C. for 3 hours to obtain a catalyst. The catalyst, denoted Catalyst F, contained 500 ppm Pt.

[0072] It can be seen from the elemental mapping image that 85% of Pt is distributed on the zeolite, and the ratio of this percentage to the percentage of zeolite in the carrier is 85% / 70%=1.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com