Semi-hydrogenated fatty acid and preparation method of the semi-hydrogenated fatty acid

A semi-hydrogenation and fatty acid technology, which is applied in the preparation/refining of fatty acids, fatty acid production, etc., can solve the problems such as the inability to adjust the proportion, the limited space for the development of the surfactant industry, and the inability to meet the refinement requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

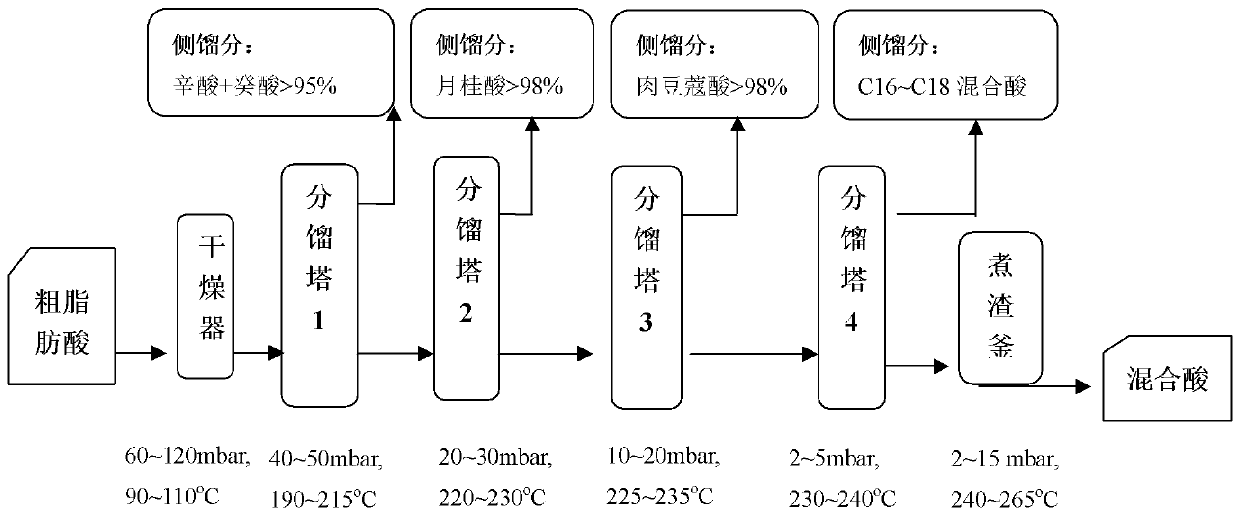

[0126] The preparation method of semihydrogenated fatty acid of the present invention is characterized in that, comprises the following steps in order:

[0127] In the hydrolysis step, the raw material oil is hydrolyzed to obtain a hydrolyzate;

[0128] In the half hydrogenation step, the product obtained in the previous step is half hydrogenated.

[0129] The hydrolysis step is a countercurrent hydrolysis step. In the hydrolysis step, the hydrolysis temperature is 240-260°C. In the hydrolysis step, the hydrolysis pressure is 4.5-5.5 MPa. Therefore, the hydrolysis step can also be referred to as a high temperature and high pressure countercurrent hydrolysis step.

[0130] In the hydrolysis step, the raw materials and deionized water are sent into the high-pressure hydrolysis tower in a countercurrent manner, and are fully contacted on the trays of the hydrolysis tower to generate a hydrolysis reaction. No catalyst is required in the hydrolysis step. Among the obtained rea...

no. 2 approach

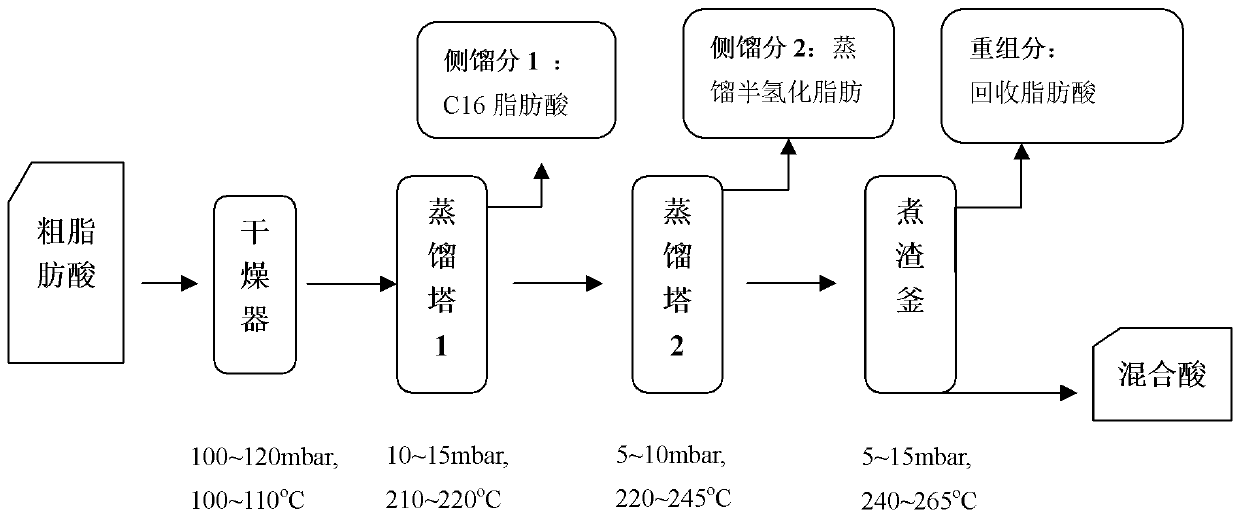

[0162] The preparation method of semihydrogenated fatty acid of the present invention is characterized in that, comprises the following steps in order:

[0163] In the hydrolysis step, the raw material oil is hydrolyzed to obtain a hydrolyzate;

[0164] In the half hydrogenation step, the product obtained in the previous step is half hydrogenated.

[0165] The hydrolysis step is a countercurrent hydrolysis step. In the hydrolysis step, the hydrolysis temperature is 240-260°C. In the hydrolysis step, the hydrolysis pressure is 4.5-5.5 MPa. Therefore, the hydrolysis step can also be referred to as a high temperature and high pressure countercurrent hydrolysis step.

[0166] In the hydrolysis step, the raw materials and deionized water are sent into the high-pressure hydrolysis tower in a countercurrent manner, and are fully contacted on the trays of the hydrolysis tower to generate a hydrolysis reaction. No catalyst is required in the hydrolysis step. Among the obtained rea...

no. 3 approach

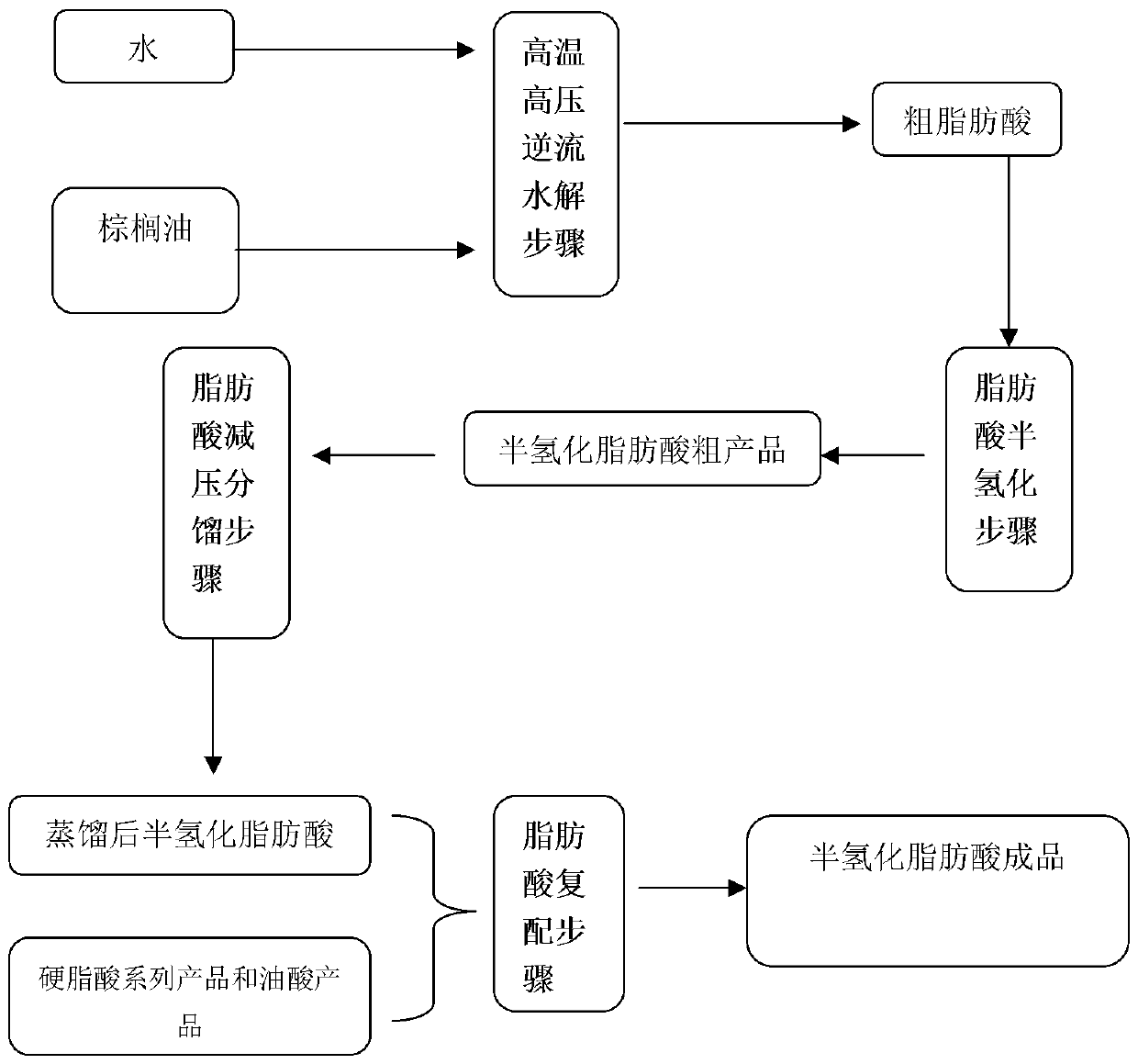

[0193] The preparation method of semihydrogenated fatty acid of the present invention is characterized in that, comprises the following steps in order:

[0194] In the hydrolysis step, the raw material oil is hydrolyzed to obtain a hydrolyzate;

[0195] In the half hydrogenation step, the product obtained in the previous step is half hydrogenated.

[0196] The hydrolysis step is a countercurrent hydrolysis step. In the hydrolysis step, the hydrolysis temperature is 240-260°C. In the hydrolysis step, the hydrolysis pressure is 4.5-5.5 MPa. Therefore, the hydrolysis step can also be referred to as a high temperature and high pressure countercurrent hydrolysis step.

[0197] In the hydrolysis step, the raw materials and deionized water are sent into the high-pressure hydrolysis tower in a countercurrent manner, and are fully contacted on the trays of the hydrolysis tower to generate a hydrolysis reaction. No catalyst is required in the hydrolysis step. Among the obtained rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com