High-ductility non-heat treatment die-casting aluminum alloy and preparation method thereof

A non-heat-treated, cast aluminum alloy technology, applied in the field of metal alloys, can solve the problems of low mechanical properties, unsatisfactory casting properties, and poor fluidity of Al-Mg alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

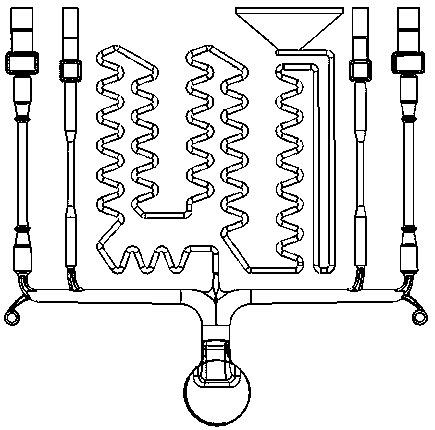

Image

Examples

Embodiment 1

[0043] This embodiment discloses a high-ductility non-heat-treated die-casting aluminum alloy, which includes the following components according to mass percentage: 5.0% Mg, 0.2% Mn, 0.1% Ti, 0.02% Sc and 94.1% Al, And the content of Fe is lower than 0.4%, and the content of Si is lower than 0.1%.

[0044]This example also discloses a method for preparing a high-ductility non-heat-treated die-casting aluminum alloy. Commercially available pure Al ingots (purity 99.9%), pure Mg ingots (purity 99.9%), Al-10Mn master alloys and Al-Ti-2Sc master alloy as raw material. The smelting device is equipped with a crucible for the furnace body.

[0045] Concrete preparation method comprises the following steps:

[0046] S1, preparing each raw material according to the mass percentage;

[0047] S2. Pre-treat each raw material and preheat to 200°C to remove moisture;

[0048] S3, putting the prepared pure Al ingot into the crucible, heating and melting;

[0049] S4. Add Al-10Mn master ...

Embodiment 2

[0060] This embodiment discloses a high-ductility non-heat-treated die-casting aluminum alloy, which includes the following components according to mass percentage: 8.6% Mg, 1.0% Mn, 0.3% Ti, 0.05% Sc and 89.5% Al, And the content of Fe is lower than 0.4%, and the content of Si is lower than 0.1%.

[0061] For the preparation method of the high-ductility non-heat-treated die-casting aluminum alloy in this embodiment, refer to Embodiment 1.

Embodiment 3

[0063] This embodiment discloses a high-ductility non-heat-treated die-casting aluminum alloy, which includes the following components according to mass percentage: 3.7% Mg, 2.0% Mn, 0.5% Ti, 0.5% Sc and 92.7% Al, And the content of Fe is lower than 0.4%, and the content of Si is lower than 0.1%.

[0064] For the preparation method of the high-ductility non-heat-treated die-casting aluminum alloy in this embodiment, refer to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com