Full hydraulic constant-power closed type driving system of tooth roller type breaker

A drive system and hydraulic system technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of high energy consumption, inability to switch the crushing speed by the motor, and inability to select the crushing force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

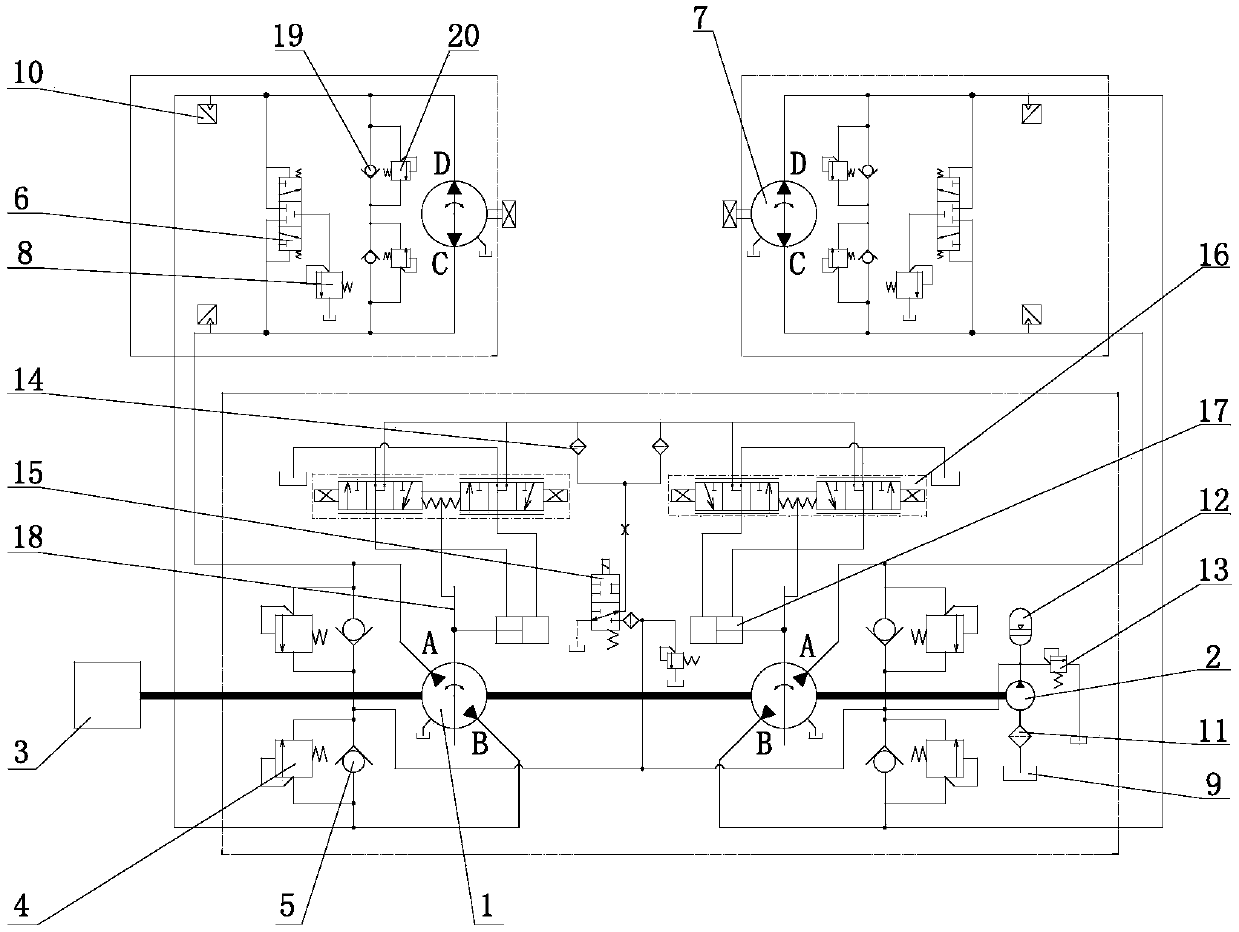

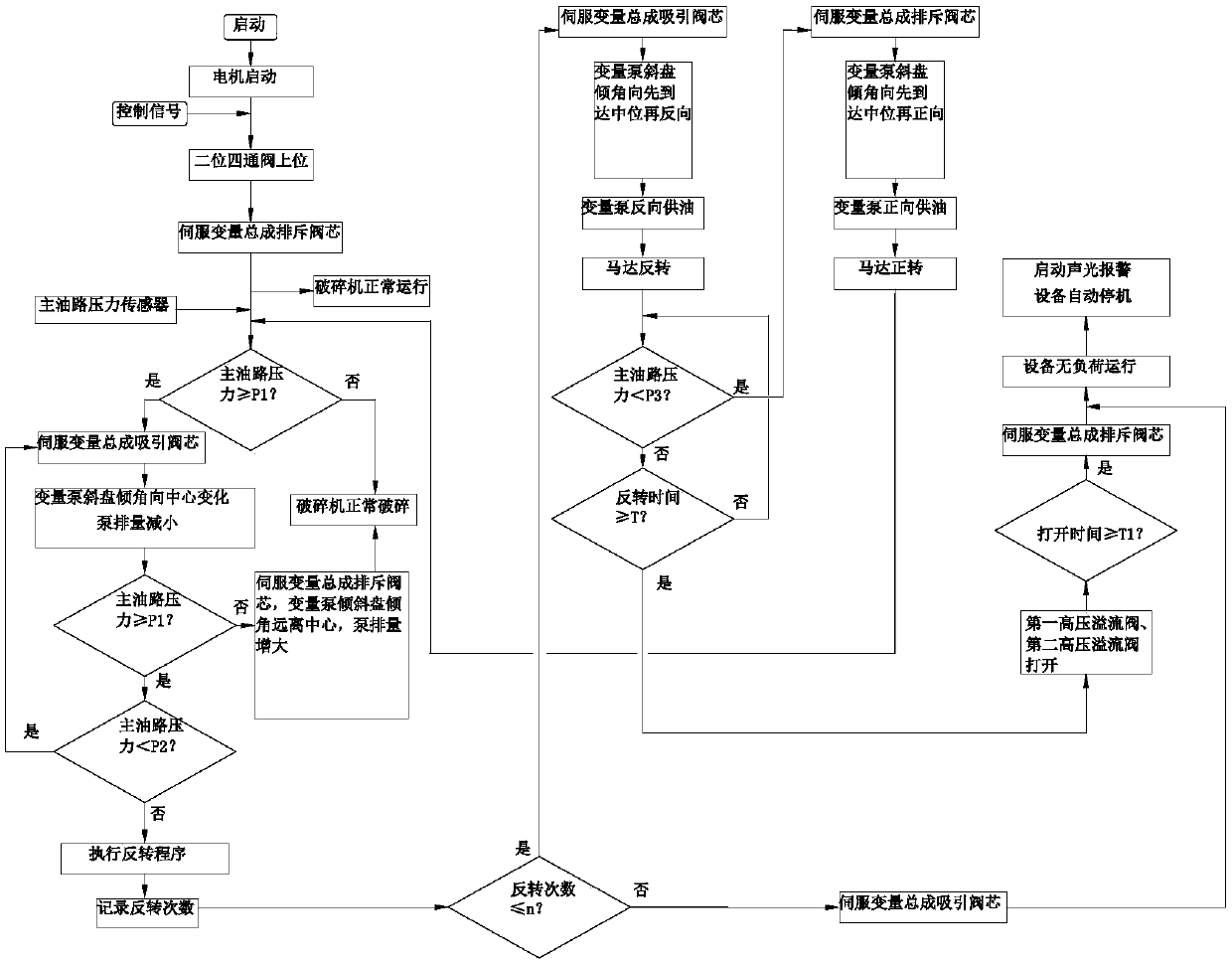

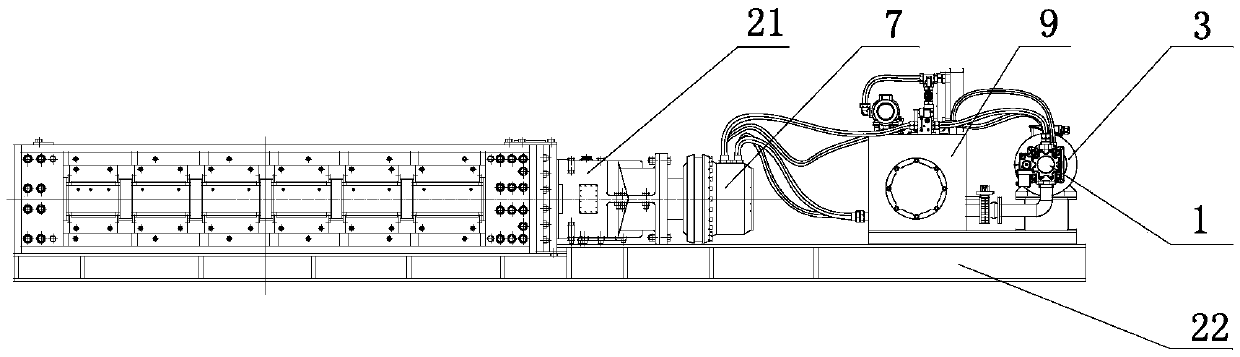

[0035] Such as Figure 1-5 As shown, the full hydraulic constant power closed drive system of the toothed roller crusher according to the present invention includes a control module and a hydraulic system. The hydraulic system includes two sets of main oil circuits, two sets of control oil circuits and one set of Supplementary oil circuit, the main oil circuit includes a two-way variable plunger pump 1, the A and B oil ports of the two-way variable piston pump 1 are respectively connected to the C and D oil ports of the hydraulic motor 7, and the A and B oil ports of the main oil circuit Pressure sensors 10 are respectively arranged on the road; the oil supply circuit includes a charge control pump 2, the oil inlet of the charge control pump 2 is connected with the fuel tank 9, and the oil outlet of the charge control pump 2 is connected with the first check valve 5 The oil inlet is connected, and the oil outlet of the first one-way valve 5 is connected with the A and B oil ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com