Method for improving actual measurement precision of mining-induced stress

A technology for mining stress and accuracy, applied in force/torque/work measuring instruments, force sensors in the holes of force-bearing structures, measuring devices, etc. limited issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

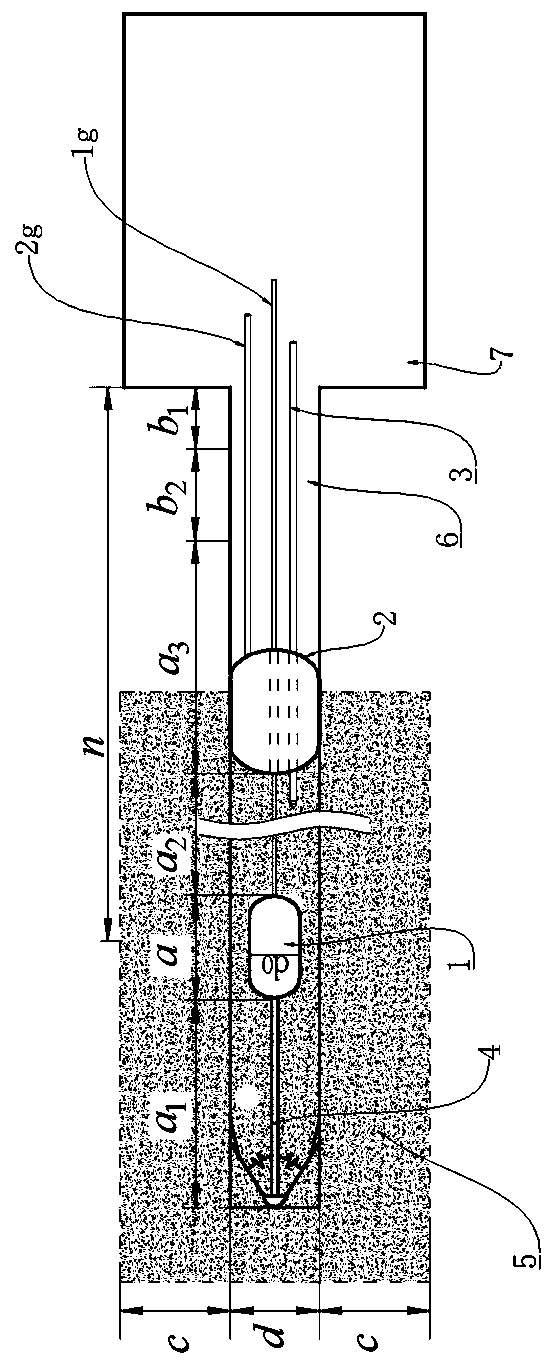

[0063] figure 1 It is a schematic diagram of a method for improving the actual measurement accuracy of mining stress of the present invention in a solid coal area. From the figure, it can be seen that a three-channel sealing plug 3, a stress gauge 1 and a fixed pressure gauge are arranged sequentially along the surrounding rock borehole 6 from shallow to deep. The outside of the distance rod 4 and the surrounding rock drilling 6 forms a consolidation zone 5 between the grout and the surrounding rock after grouting, and the diameter of the surrounding rock drilling 6 in the figure is d, The strain gauge diameter is d 0 , the slurry diffusion distance outside the surrounding rock drilling is c, and the roadway crushing zone width is b 1 , the roadway plastic zone width is b 2 ; Implement concrete method and step of the present invention to be respectively:

[0064] Step 1: Take a coal sample in the actual coal area to be measured, and test the uniaxial compressive strength...

Embodiment 2

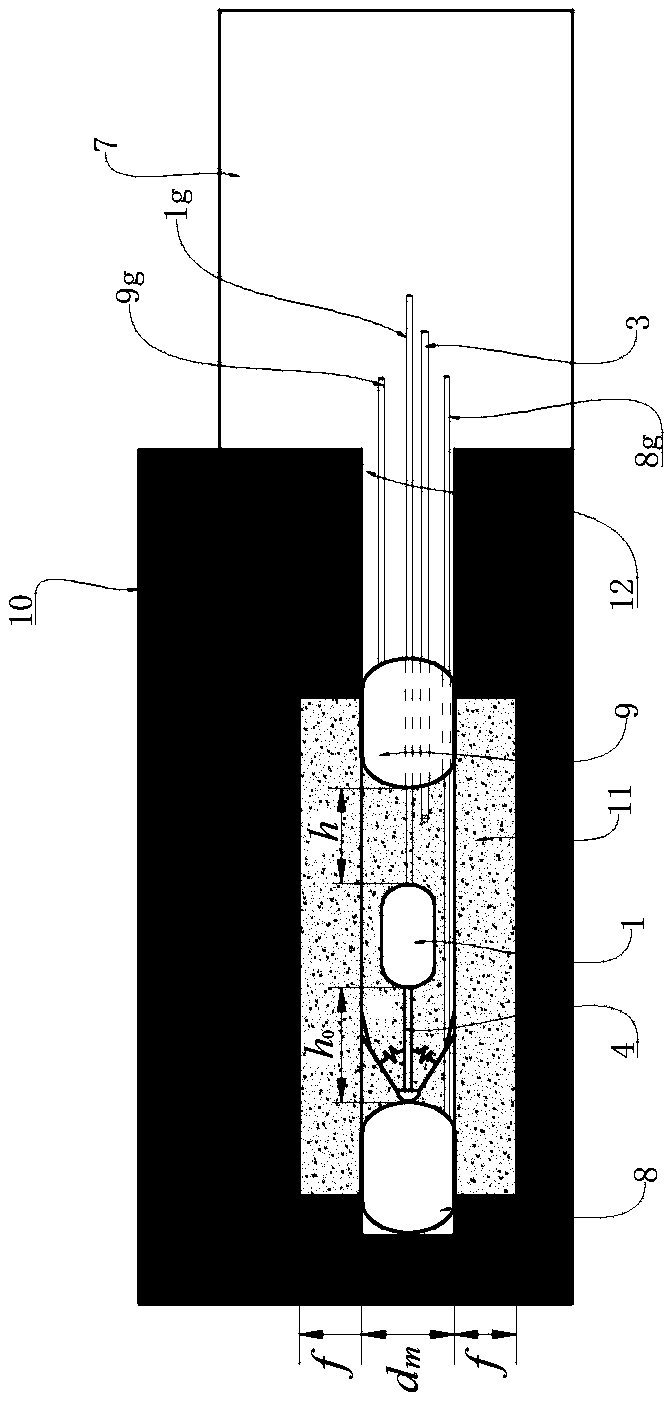

[0076] Such as figure 2 , the method and specific implementation steps to improve the accuracy of the actual measurement of mining stress when the test location is in the yielding coal pillar area are as follows:

[0077] It can be seen from the figure that there are four-channel sealing plugs 9, stress gauges 1, distance rods 4 and single-channel sealing plugs 8 arranged along the coal pillar borehole 12 from shallow to deep. After grouting, the slurry and coal pillar consolidation zone 11 is formed. The diameter of the coal pillar drilling hole in the figure is d m , The strain gauge diameter is d 0 , the slurry diffusion distance outside the coal pillar borehole is f , the distance between the stress gauge and the single-channel grout stopper is h 0 ; The distance between the stress gauge and the four-channel grout stopper is h, The concrete method and steps of implementing the present invention are respectively:

[0078] Step 1: Take a complete coal sample of the...

Embodiment 3

[0087] The method and specific implementation steps for improving the accuracy of the actual measurement of the mining stress when the actual measurement position of the mining stress is in the solid coal area, if the actual measurement position is in the rock mass area, the hole is grouted, and the grouting pressure is preferably 1 ~ 10MPa , if the uniaxial compressive strength of the rock mass is greater than 40MPa, the grouting pressure is 4~10MPa, and if the uniaxial compressive strength of the rock mass is less than 40MPa, the grouting pressure is 1~4MPa, which meets the requirements of the broken zone of the borehole. The rock mass in the plastic zone can be consolidated by grouting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com