Method and device for simultaneously determining moisture content and impregnating compound content in glass fibers

A technology of glass fiber and sizing agent, which is applied to measuring devices, analyzing materials, and using nuclear magnetic resonance to analyze, etc., and can solve problems such as long testing time and affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

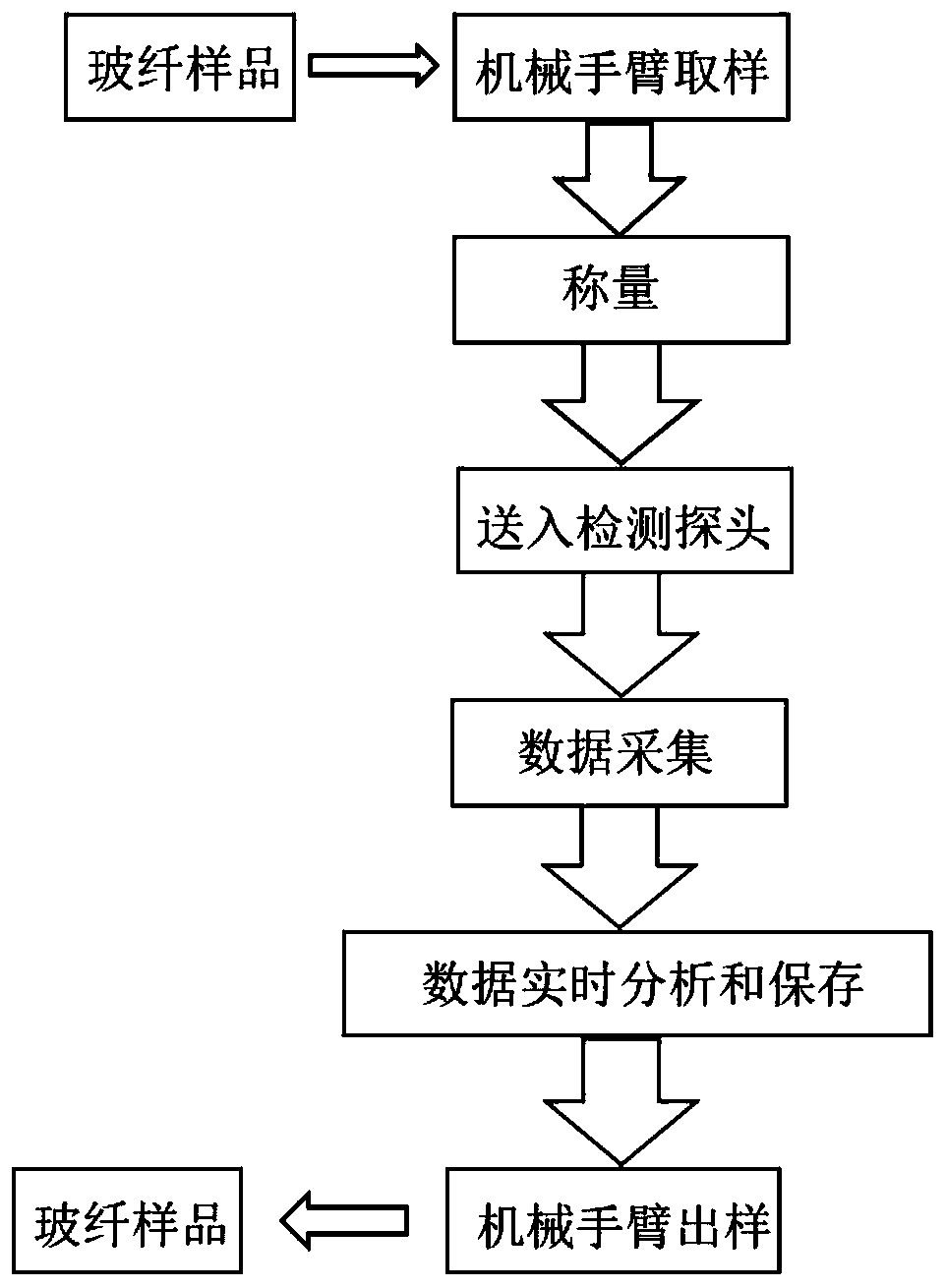

[0060] This embodiment provides a method for simultaneously measuring moisture and sizing in glass fibers, such as figure 1 As shown, the workflow of the test method is mainly divided into the following seven steps: 1. Establishing the working curve; 2. Sampling by the sampling device; 3. Putting it into the weighing device for weighing; Collection; 6. Data real-time analysis and storage; 7. Sampling device for sampling.

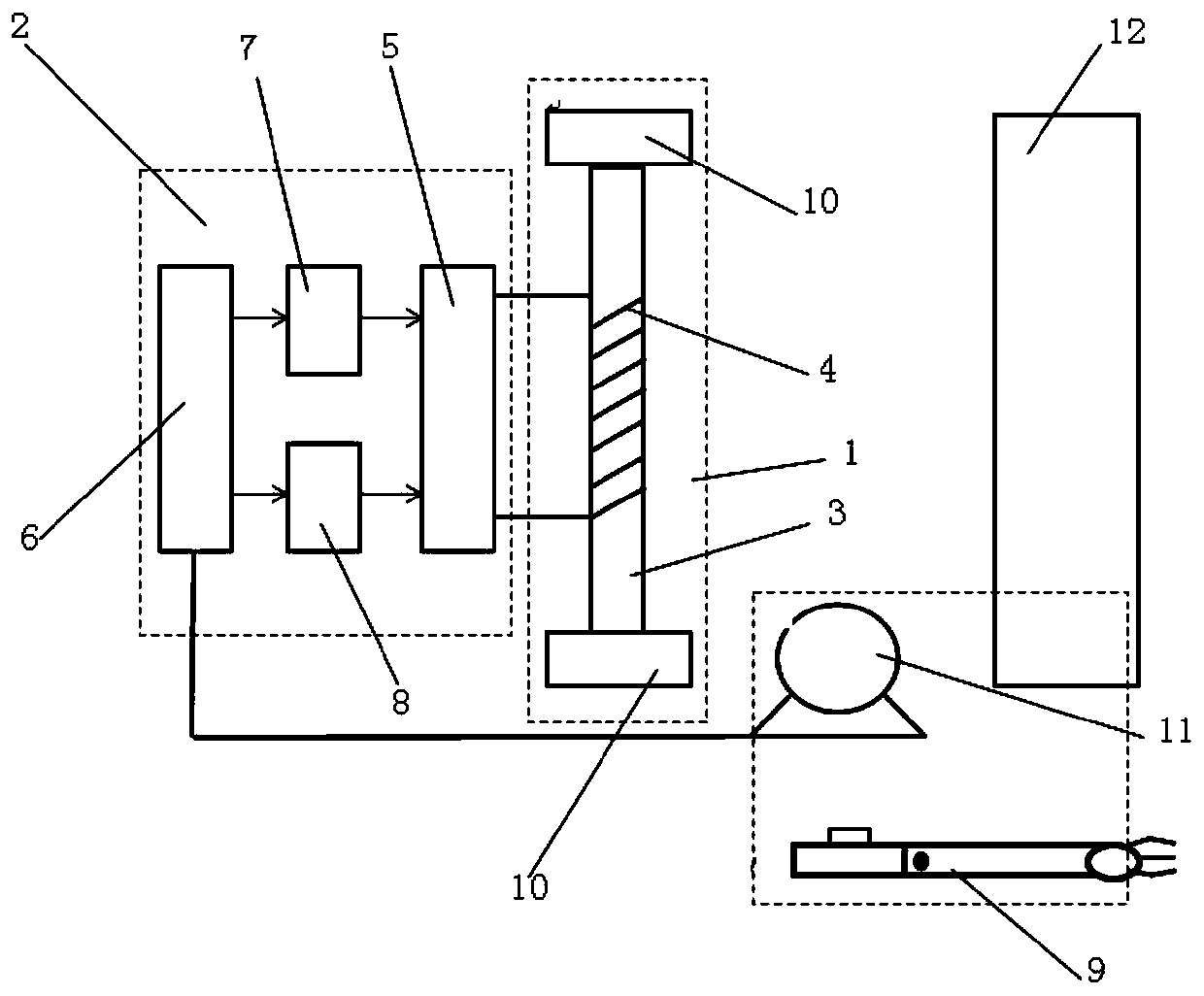

[0061] The device used in this embodiment, such as figure 2 shown, including,

[0062] The sampling device 9 is used to grab or return the glass fiber sample to be tested in the glass fiber transmission path 12 (on the production line). In this embodiment, the sampling device is a mechanical arm;

[0063] Weighing device 11, is used for weighing the quality of glass fiber sample;

[0064] The nuclear magnetic resonance detection device includes a detection probe system 1 and a spectrometer control system 2, and the spectrometer control system 2 controls ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com